High-speed intelligent plastic bag arranging and bundling mechanism

A strapping mechanism and plastic bag technology, which is applied to the parts of strapping machines, paper product packaging, and types of packaging items, etc., can solve the problem of inability to remove unqualified products, narrow application range of strapping machines, and inability to meet the characteristics of plastics with different thicknesses. Bag binding and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing:

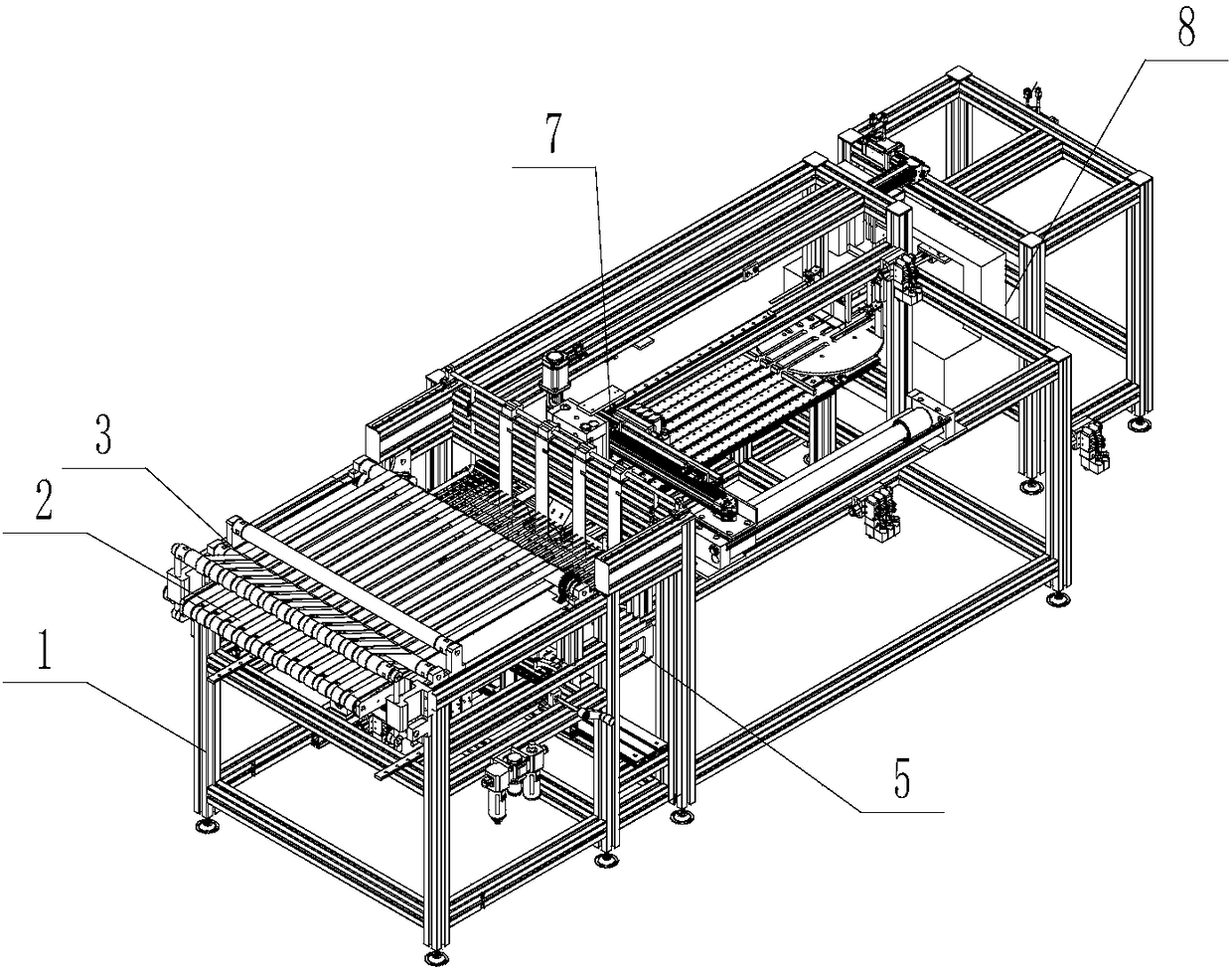

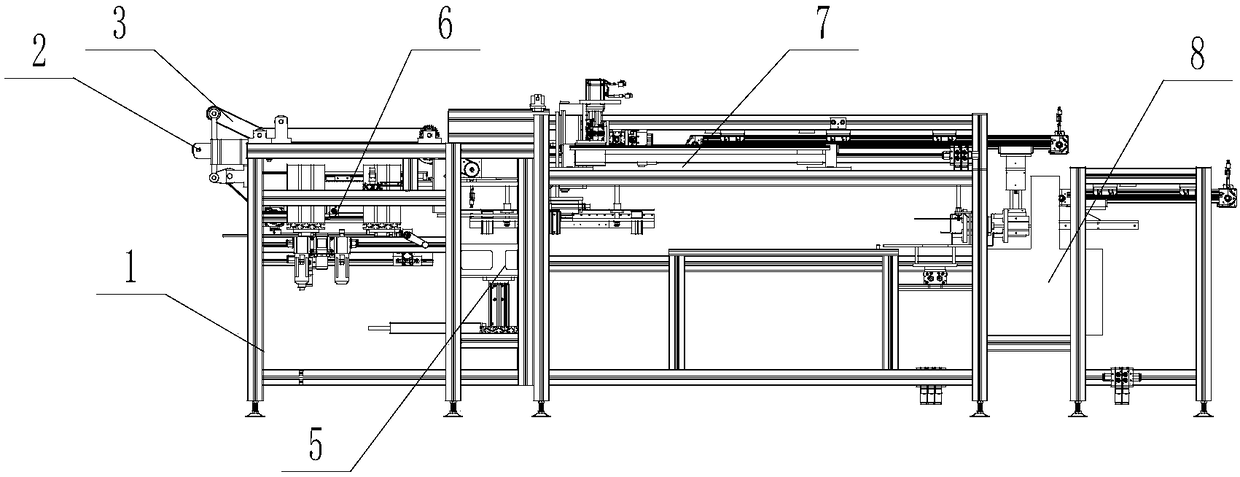

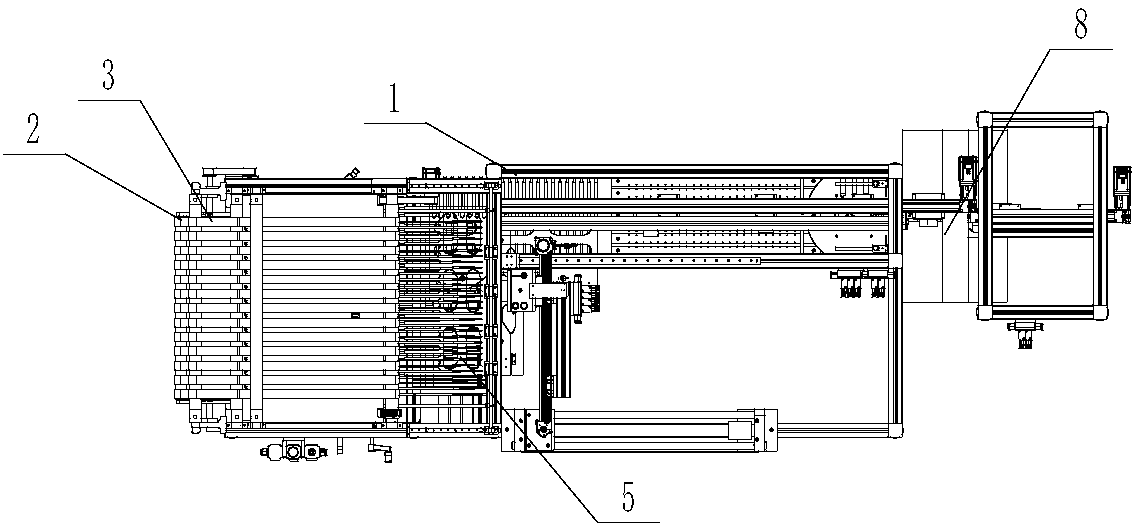

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 ,and Figure 15 As shown, a high-speed intelligent plastic bag sorting and binding mechanism includes an overall frame 1, a feeding transmission module 2, a guiding module 4, a blanking chute module 5, a reciprocating push bar module 6, a transfer module 7 and a binding module 8 , the feeding conveying module 2, guiding module 3, lane-dividing baffle module 4, blanking chute module 5, reciprocating push bar module 6, transfer module 7 and binding module 8 are all arranged on the overall frame 1, The feeding conveying module 2 is arranged at the front end of the overall frame 1, and the last process at the front end of the overall frame 1 is the outlet of the bag making machine, and the bag making machine of the last process performs horizontal and vertical processing of the plastic bags produced. The cutting, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com