Solar cell glass plate offline reflective strip sticking device

A solar cell and glass plate technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inability to control the quality of the coating, low production efficiency, and increase production costs, and achieve simple structure and equipment manufacturing costs. low, efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

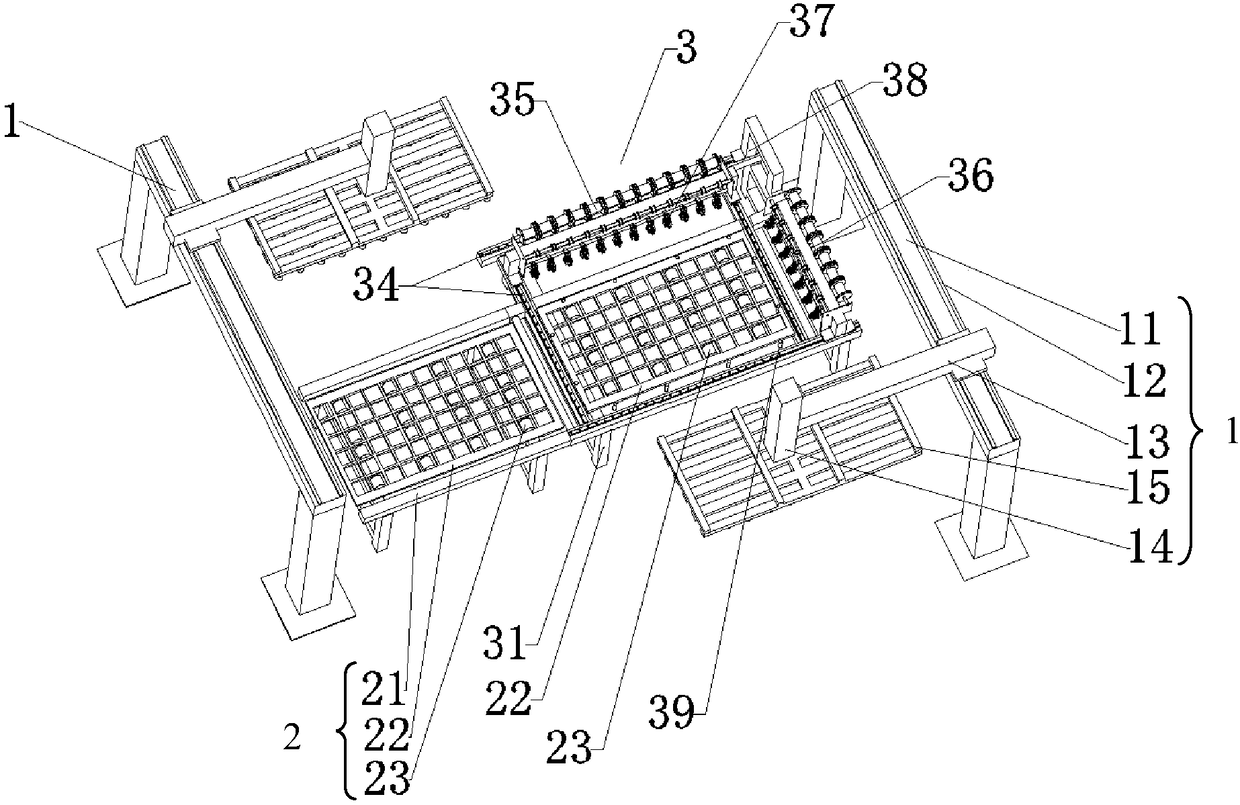

[0024] An off-line reflective strip sticking device for solar battery glass plates of the present invention includes a grabbing device 1, a preheating device 2 and a pasting device 3. The preheating device 2 and the pasting device 3 are placed adjacent to each other. The glass plate is heated, and then the reflective strip is pasted by the pasting device 3; there are two grabbing devices 1, one of which grabs the glass plate into the preheating device 2, and the other grabbing device 1 Grab the glass plate in the sticking device 3; Wherein,

[0025] Preheating device 2 comprises preheating support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com