Cargo transmission method for vending machine platform

A technology for vending machines and goods, which is applied to coin-free or similar appliances, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. The platform design and control process is complex, the delivery structure manufacturing cost is high, and the control process is complicated, which can simplify the design difficulty, run smoothly, and have fewer components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

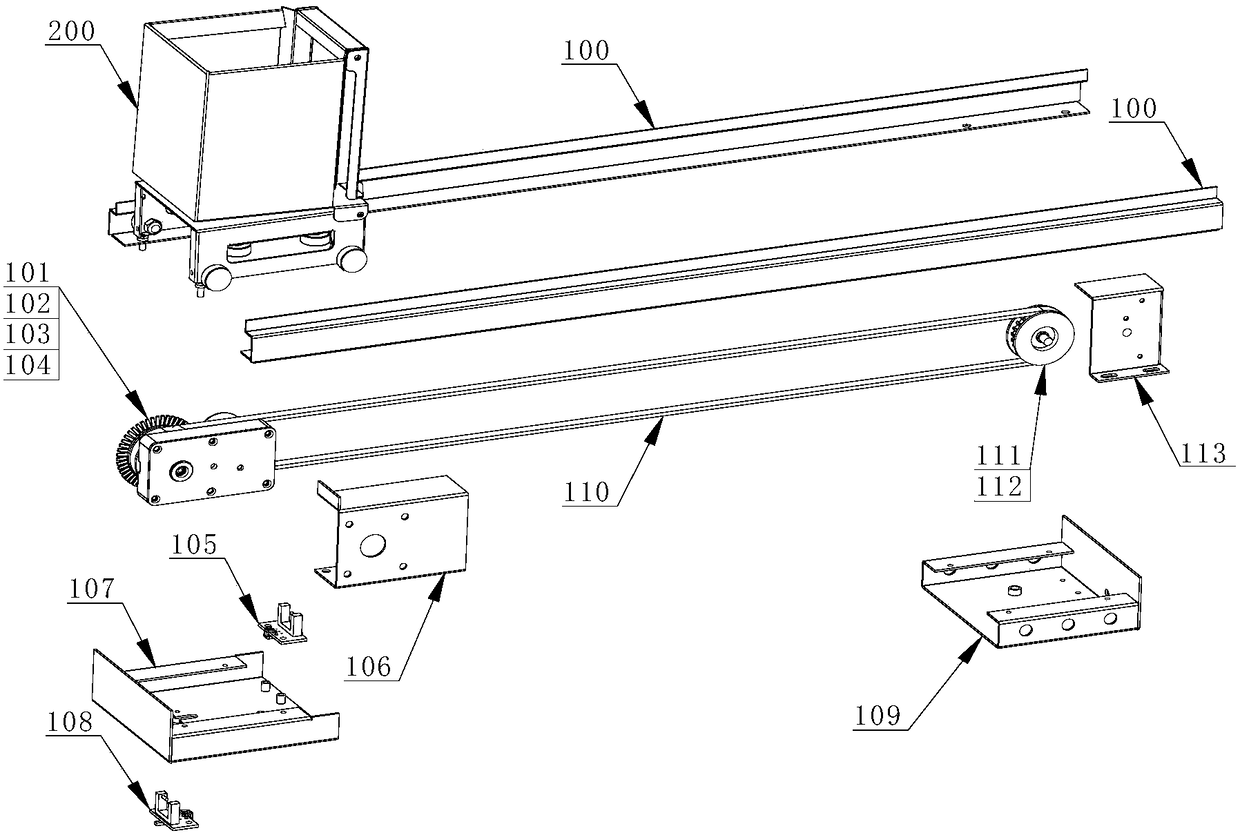

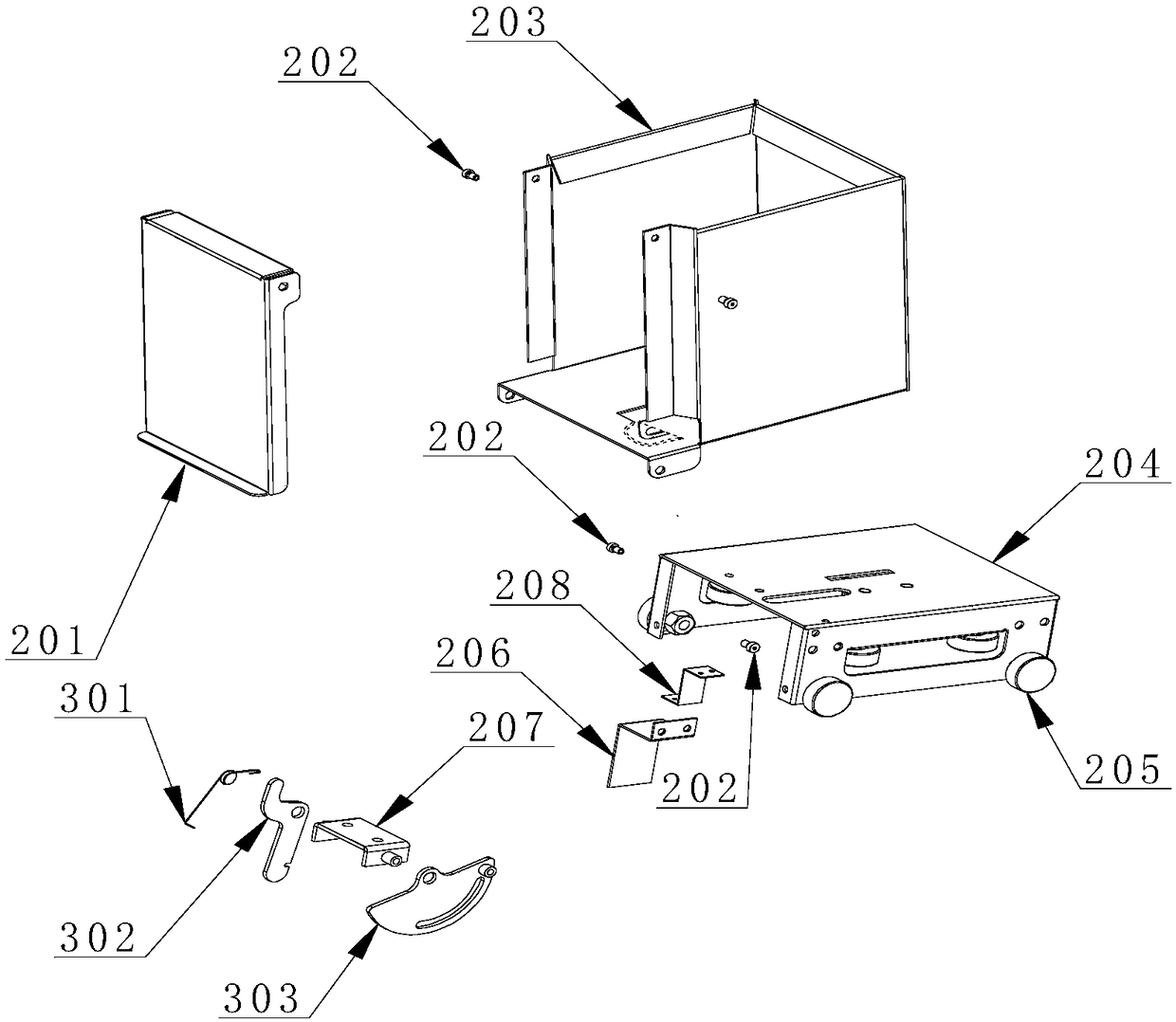

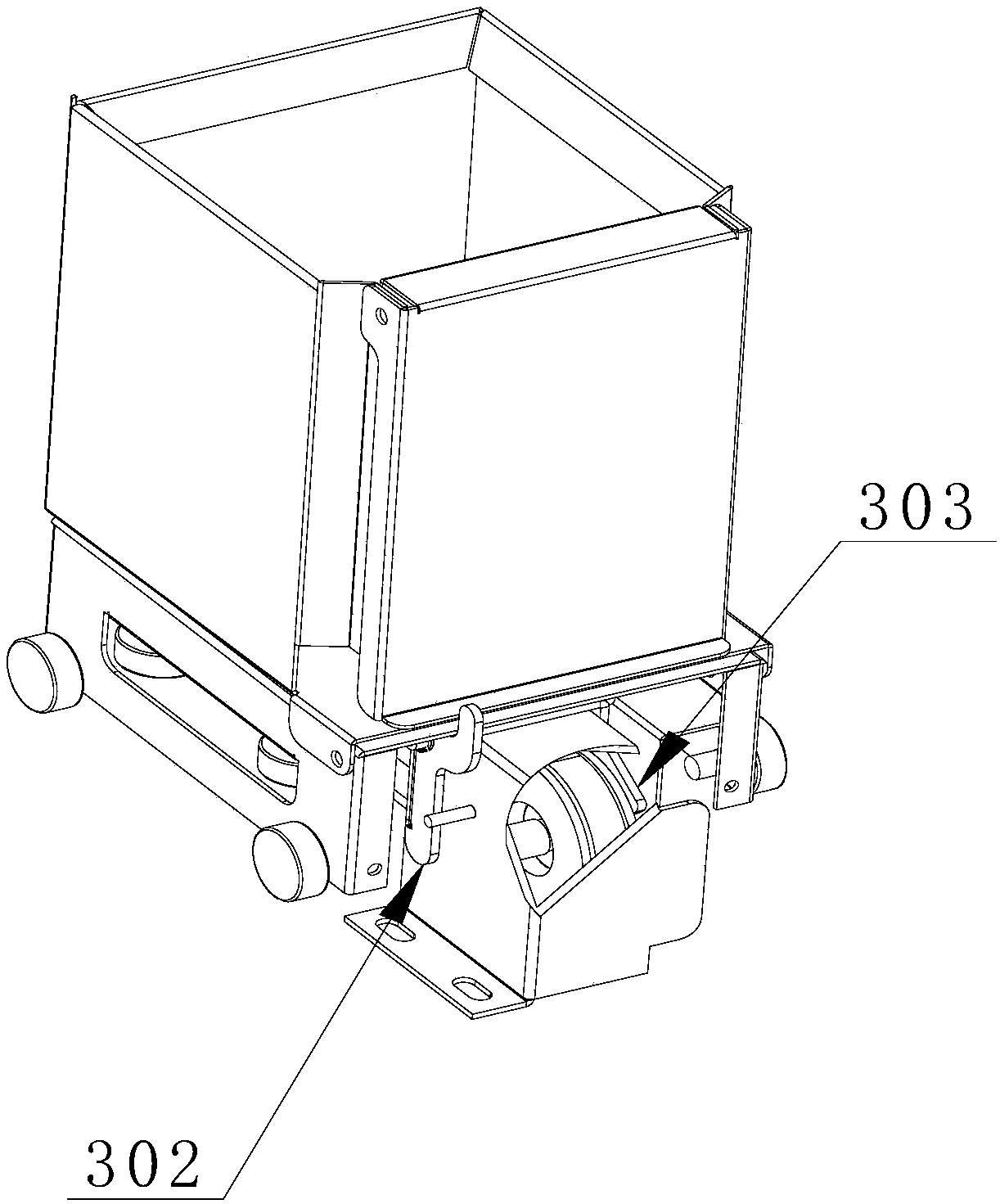

[0041] Embodiment 1: as Figure 1~5 , a method for delivering goods on a vending machine platform, comprising the following steps:

[0042] Step 1: At the starting position, load the goods;

[0043] At the starting position, the goods fall into the dumper to complete the loading of the goods;

[0044] Step 2: Transfer the goods to the unloading position;

[0045] Driven by the driving mechanism, the cargo loading mechanism moves forward until it reaches the unloading position; the cargo loading mechanism includes a dump seat (204) and a dump bucket (200); the dump bucket seat is hinged to the dump bucket;

[0046] Step 3: Dump the goods out of the tipping bucket at the unloading position;

[0047] At the unloading position, the tipping bucket is tilted, and the goods in the tipping bucket are poured out; the goods are released from the warehouse;

[0048] Step 4: Reset;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com