Liquid crystal display panel, method for internally installing polarizer in liquid crystal display panel and production method of liquid crystal display panel

A technology of liquid crystal display device and liquid crystal panel, which is applied in the direction of photographic plate-making process, optics, optical elements, etc. on the pattern surface, which can solve the problems of difficult light on-off control, etc., so as to improve the service life, improve the utilization rate, and use high The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

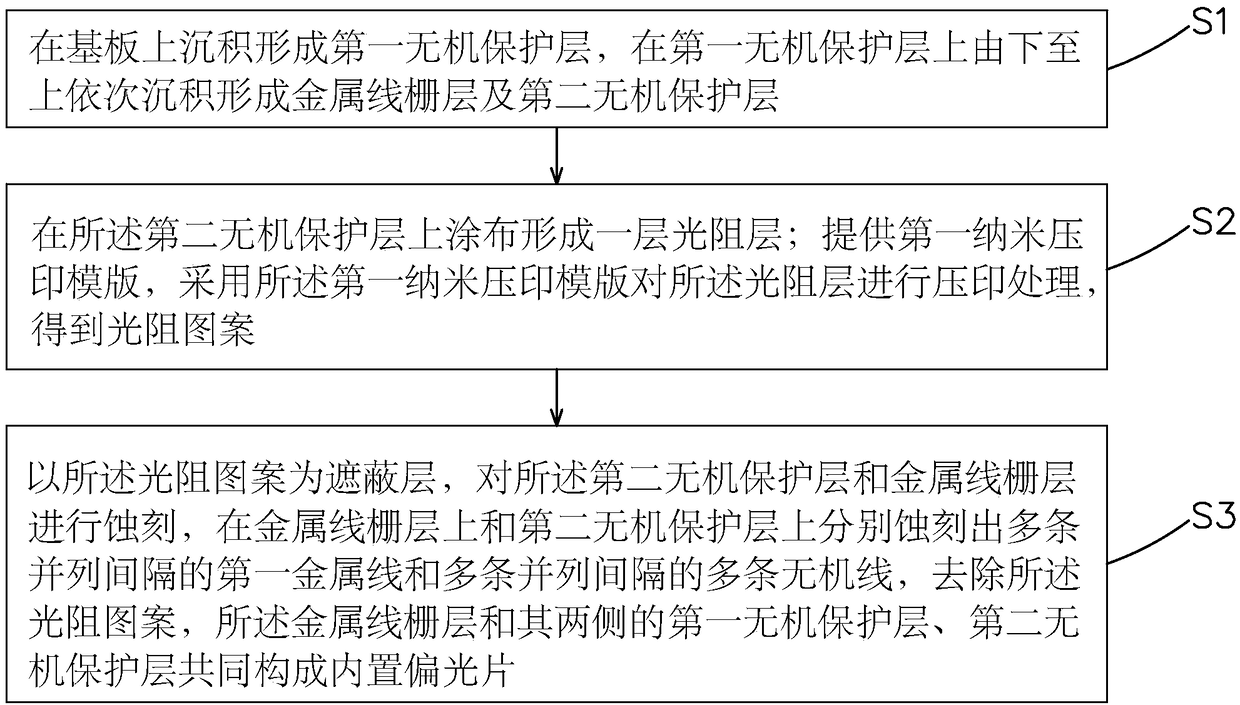

[0050] see figure 2 , the present invention firstly provides a kind of manufacturing method of built-in polarizer 30, comprises the following steps:

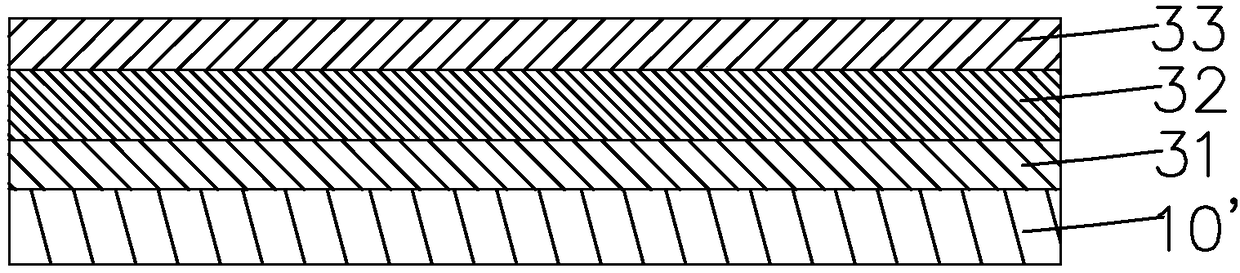

[0051] Step S1, such as image 3 As shown, a substrate 10' is provided, a first inorganic protection layer 31 is deposited and formed on the substrate 10', and a metal wire grid layer 32 and a second inorganic protection layer 33 are sequentially deposited on the first inorganic protection layer 31 from bottom to top. .

[0052] Step S2, such as Figure 4-6 As shown, a photoresist layer 80 is formed by coating on the second inorganic protective layer 33; a first nanoimprint template 90 is provided, and the photoresist layer 80 is processed by using the first nanoimprint template 90 In the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com