Piston transfer type deep sea sediment pressure holding sampler

A deep-sea sediment and transfer technology, applied in sampling devices and other directions, can solve the problems of not ensuring the in-situ characteristics of pressure-holding samples, unfavorable acquisition of sediments, and unstable pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

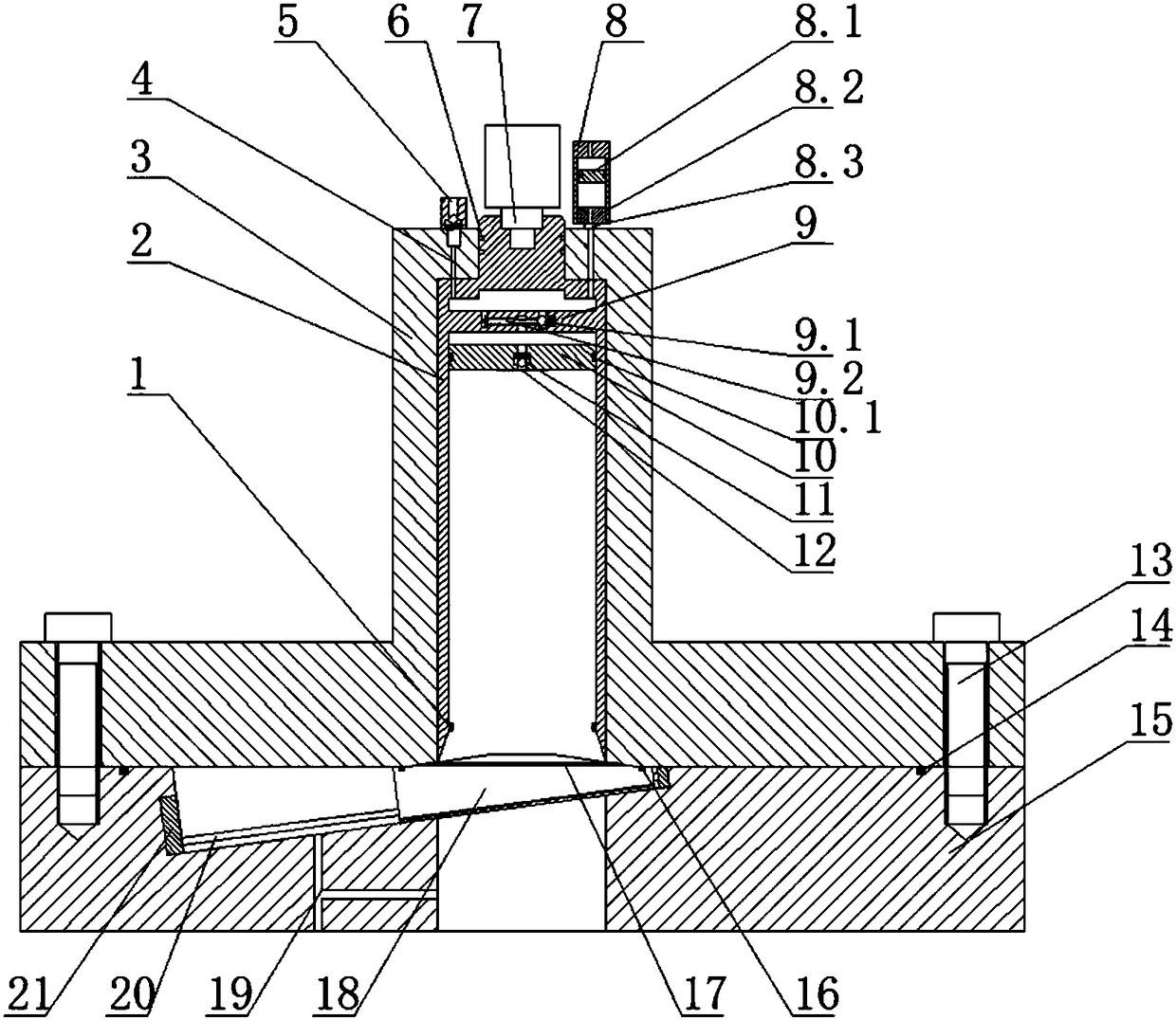

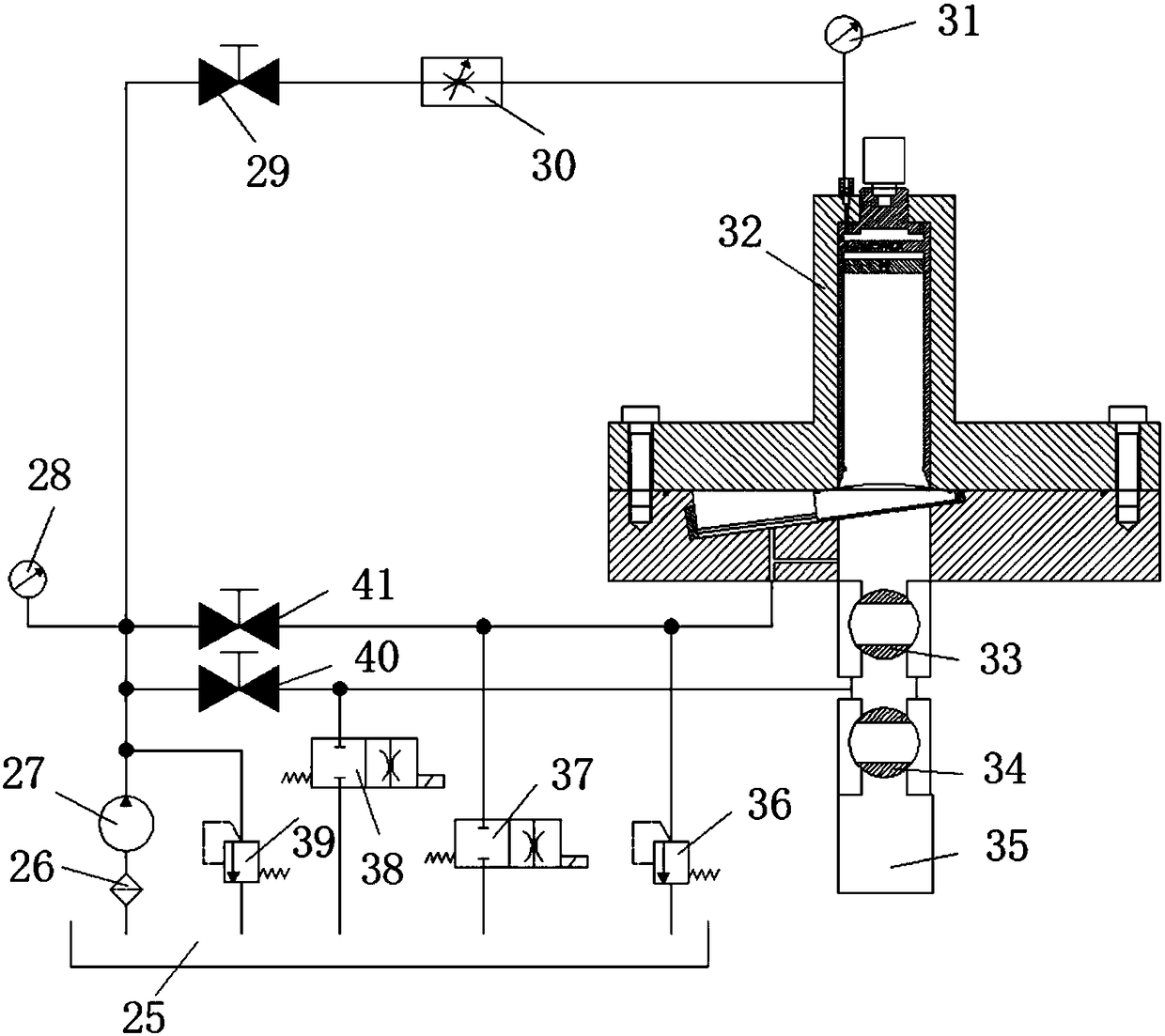

[0018] The piston transfer type deep-sea sediment pressure holding sampler of the present invention includes a mechanical structure part and a sample transfer pressure holding part;

[0019] The mechanical structure part includes a pressure holding cylinder 3, a sampling cylinder 2, and a push rod 7; the upper and lower end caps of the pressure holding cylinder 3 are ring-shaped, the sampling cylinder 2 is set in the pressure holding cylinder 3, the lower end of the sampling cylinder 2 is open, and its upper end is closed And stretch into the ring of the upper end cover of the pressure-holding cylinder 3, and seal it through the sealing ring. There is a slope groove inside the cover 15 and a wedge block 18 and a motor screw 20 are provided. The angle of the slope is a self-locking angle. The wedge block 18 is fixed on the screw slide seat, and the motor screw 20 drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com