Determination method of reflection intensity at melting point of photonic crystal fiber ring based on otdr

A photonic crystal fiber, reflection intensity technology, applied in the measurement of refractive power, testing optical performance and other directions, can solve the problem of inability to measure the back-reflection light intensity of the melting point in the photonic crystal fiber optic gyroscope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

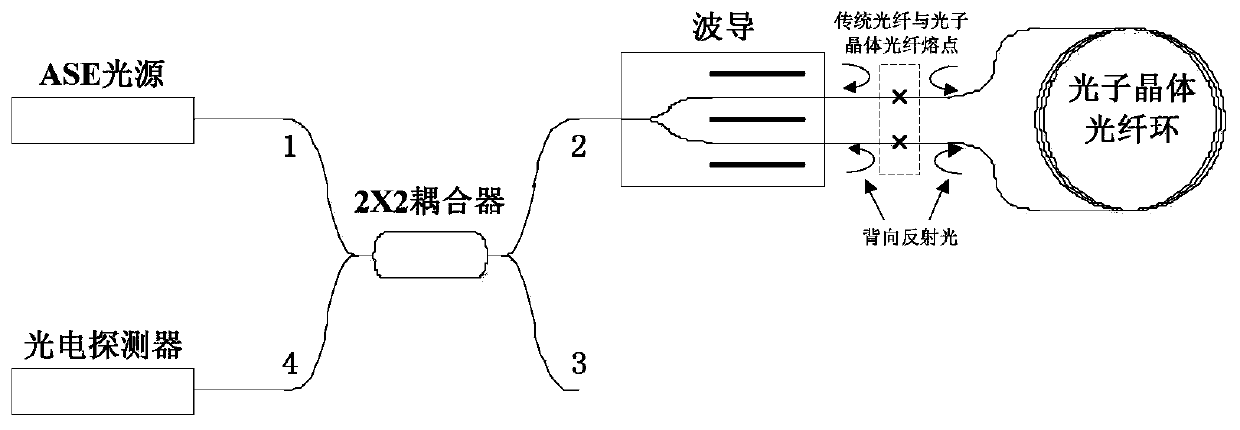

[0029] The photonic crystal fiber optic gyroscope is an angular velocity sensor based on the Sagnac effect. The basic principle is as follows: figure 1 As shown, the transmission path of the signal light wave is: the light emitted by the light source enters the coupler through port 1 of the 2×2 coupler, and outputs from the ports 2 and 3 of the coupler after beam splitting, and the port 2 of the coupler is connected to the input end of the waveguide. After entering the optical fiber ring through the waveguide, it interferes for a circle, and outputs from the waveguide, enters the coupler through the coupler 2 port, and outputs from the coupler 1 and 4 ports in reverse after the coupler splits the beam, and the coupler 4 port is connected to the detector , the output interference light wave enters the detector for detection. figure 1 At the same time, the back-reflected light wave generated by the melting point is marked, and its transmission path is the same as the output inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com