A method and system for producing carbon dioxide from coal-to-methanol

A carbon dioxide and coal-to-methanol technology, which is applied in chemical instruments and methods, microorganism-based methods, biochemical equipment and methods, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

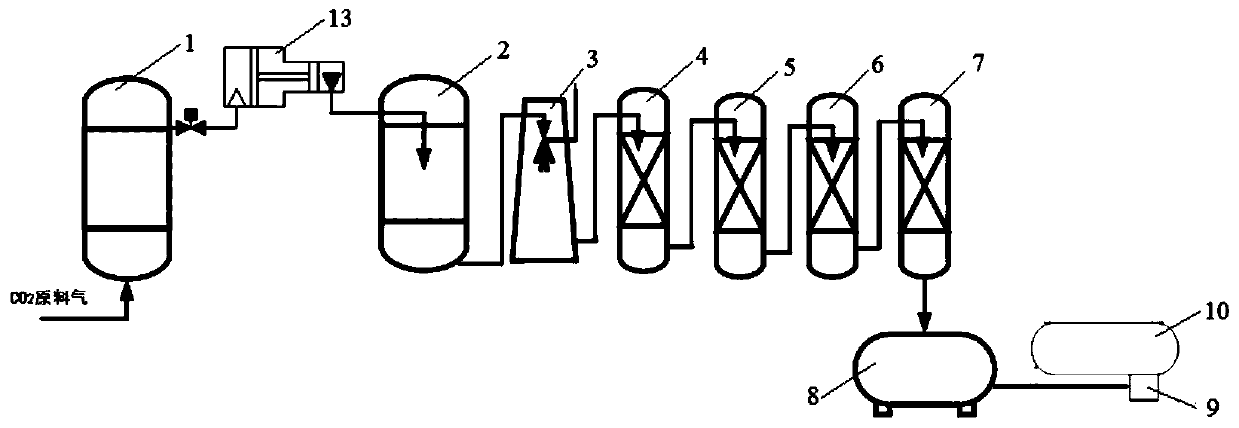

[0082] Such as figure 1 As shown, the system of fixed coal-to-methanol production of carbon dioxide in this embodiment includes a carbon dioxide pretreatment system, a carbon dioxide supply system, and a carbon dioxide absorption system; the carbon dioxide pretreatment system includes a pre-desulfurization tower 1, a hydrolysis tower 2, a cooling tower 3, and a fine desulfurization tower 4. Dehumidification tower 5, dealcoholization tower 6, liquefied distillation tower 7 and liquefied carbon dioxide storage tank 8; the carbon dioxide supply system includes a carbon dioxide dissolution pool 9; the carbon dioxide absorption system includes a microalgae cultivation pool 10.

[0083] The raw material gas is the exhaust gas from the medium and low temperature methanol washing device in the production of coal-to-methanol, which contains CO 2 98.9-99.2%, pressure 0.17-0.19MPa, temperature 4-10℃, containing CO 1.4-1.6%, H 2 0.45-0.6%, CH 4 0.015-0.03%, N 2 0.003-0.005%, H 2 S ...

Embodiment 2

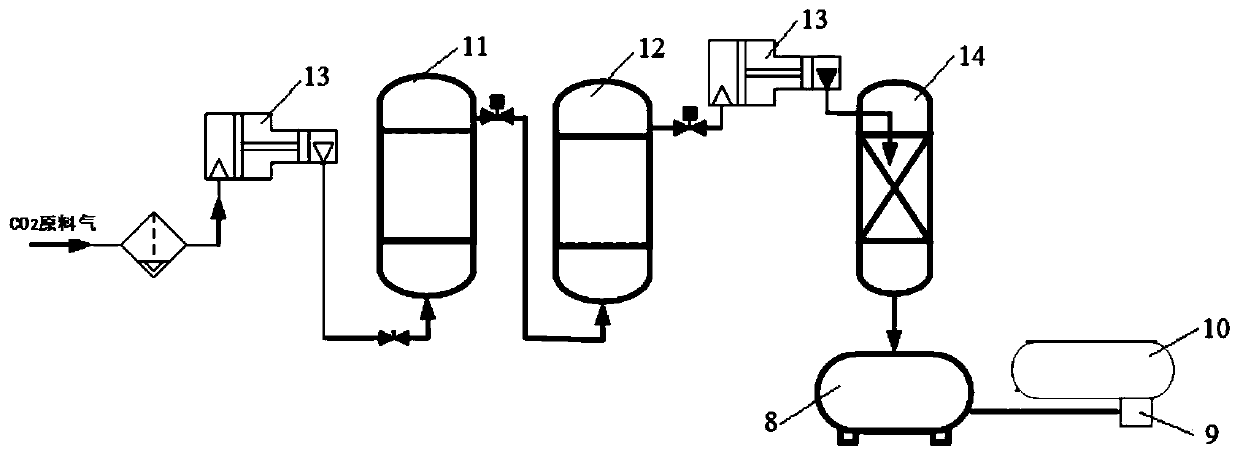

[0088] Such as figure 2 As shown, the system of fixed coal-to-methanol production of carbon dioxide in this embodiment includes a carbon dioxide pretreatment system, a carbon dioxide supply system and a carbon dioxide absorption system; the carbon dioxide pretreatment system includes a desulfurization tower 11, an adsorption tower 12, a compressor 13, a condensation tower 14 and The liquefied carbon dioxide storage tank 8, the carbon dioxide supply system includes a carbon dioxide dissolution pool 9; the carbon dioxide absorption system includes a microalgae cultivation pool 10.

[0089] The raw material gas is the exhaust gas from the medium and low temperature methanol washing device in the production of coal-to-methanol, which contains CO 2 60-70%, pressure 0.10-0.12MPa, temperature 10-20℃, containing N 2 28-33%, others are CO, H 2 , CH 4 , H 2 S, COS and CH 3 OH and other impurities.

[0090] The raw material gas first undergoes gas-liquid separation, then enters t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com