Glue for corrugated paper

A corrugated paper and glue technology, applied in the direction of adhesive types, adhesive additives, non-polymer adhesive additives, etc., can solve the problems affecting the normal use of corrugated paper, decrease in strength, poor moisture resistance of corrugated paper, etc. The effect of improving strength and good moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

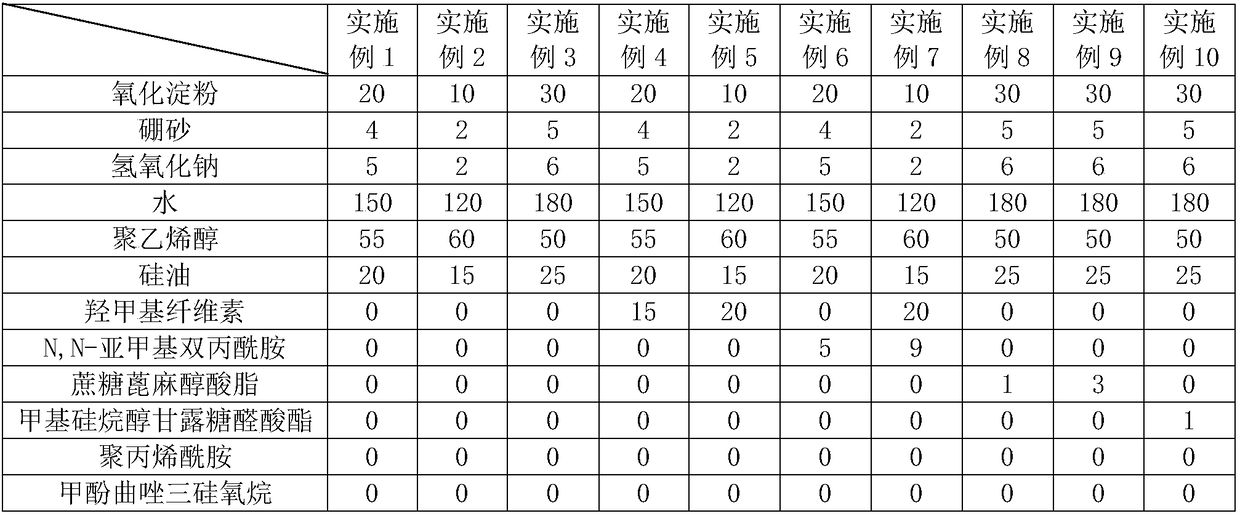

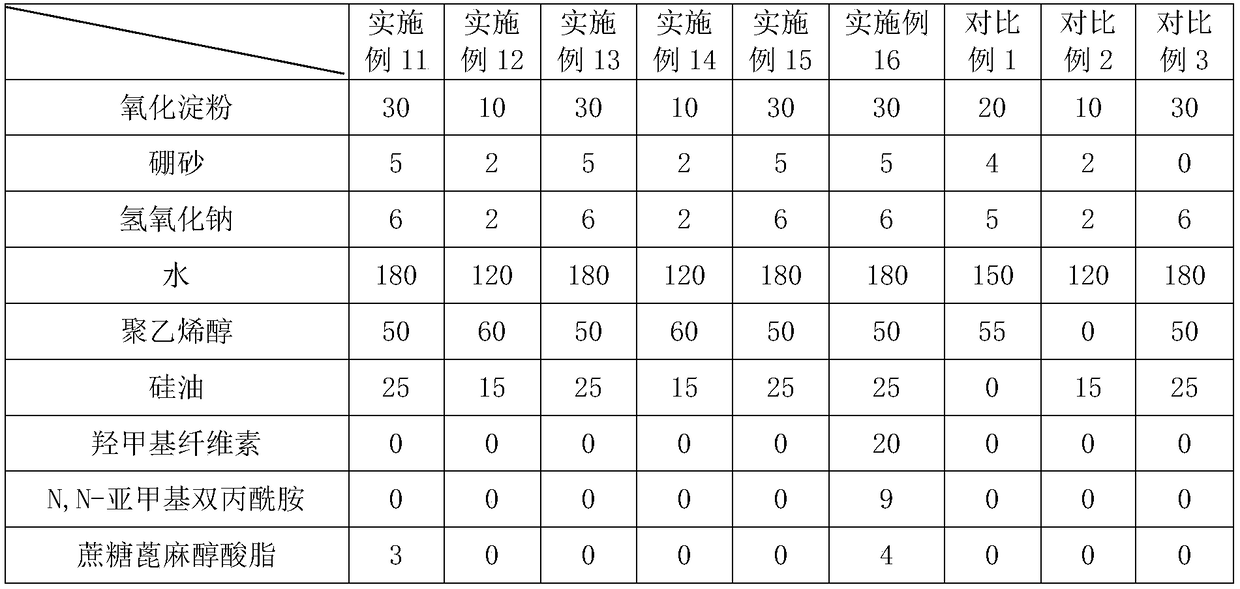

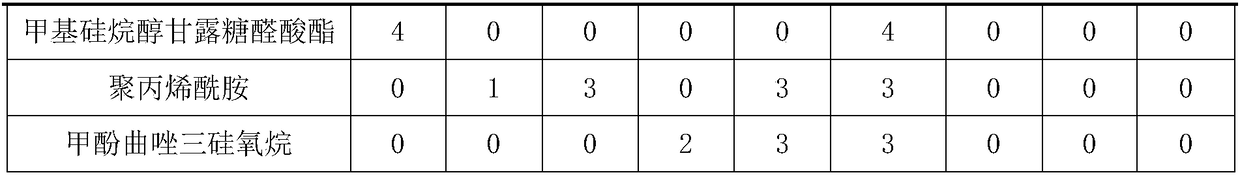

[0028] Embodiment 1: A kind of glue for corrugated paper, the components and contents in the raw materials are shown in Table 1, wherein the unit of the content of each component in Table 1 is kg, and the oxidized starch is wheat oxidized starch, which is prepared by oxidation of wheat starch .

[0029] The preparation method of the glue for corrugated paper is as follows: take each component in the glue material for corrugated paper, mix them and stir evenly to obtain the glue for corrugated paper.

Embodiment 2

[0030] Example 2: A glue for corrugated paper, the components and contents in the raw materials are shown in Table 1, wherein the content of each component in Table 1 is in kg, and the oxidized starch is corn oxidized starch, which is prepared by oxidation of corn starch .

[0031] The preparation method of the glue for corrugated paper is as follows: take each component in the glue material for corrugated paper, mix them and stir evenly to obtain the glue for corrugated paper.

Embodiment 3

[0032] Embodiment 3: A kind of glue for corrugated paper, each component and content in the raw material are as shown in Table 1, wherein the unit of each component content in Table 1 is kg, oxidized starch is cassava oxidized starch

[0033] The preparation method of the glue for corrugated paper is as follows: take each component in the glue material for corrugated paper, mix them and stir evenly to obtain the glue for corrugated paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com