Method for synthesizing other amiprid from amiprid

A technology for the synthesis and compound of amidines, applied in the direction of organic chemistry, etc., can solve the problems of cumbersome product post-treatment, harsh reaction conditions, long reaction time, etc., and achieve the effect of simple product separation and purification, mild reaction conditions, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

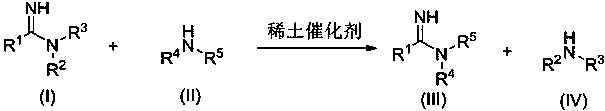

Method used

Image

Examples

Embodiment 1

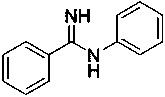

[0025] The preparation of N-phenyl benzamidine, structural formula is as follows:

[0026]

[0027] Under nitrogen protection, the raw material N-methyl-N-phenylbenzamidine (0.5 mmol) and the catalyst Lu(CH 2 Ph) 3 (10mol%), aniline (1 mL), reacted at 60 °C for 12 h, and the isolated yield of the product was 91%.

[0028] 1 H NMR (400 MHz, CDCl3): δ 7.87-7.86 (m, 2H), 7.50-7.43 (m, 3H), 7.40-7.36 (m, 2H), 7.11-7.07 (m, 1H), 7.01-7.00 ( m, 2H), 4.93 (s, 2H).

Embodiment 2

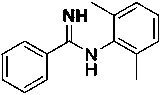

[0030] The preparation of N-(2,6-dimethylphenyl) benzamidine, the structural formula is as follows:

[0031]

[0032] Under nitrogen protection, the raw material N-methyl-N-phenylbenzamidine (0.5 mmol) and the catalyst Lu(CH 2 Ph) 3 (10mol%), 2,6-dimethylaniline (1 mL), reacted at 60 °C for 12 h, and the isolated yield of the product was 83%.

[0033] 1 H NMR (400 MHz, CDCl3): δ 7.87-7.85 (m, 2H), 7.45-7.38 (m, 3H),7.05-7.03 (m, 2H), 6.90-6.87 (m, 1H), 4.60 (s, 2H), 2.13 (s, 6H).

Embodiment 3

[0035] The preparation of N-(2,6-dimethylphenyl)-4-methylbenzamidine, the structural formula is as follows:

[0036]

[0037] Under nitrogen protection, the raw material N-methyl-N-phenylbenzamidine (0.5 mmol) and the catalyst Lu(CH 2 Ph) 3 (10mol%), 4-methylaniline (1 mL), reacted at 60 °C for 12 h, and the isolated yield of the product was 76%.

[0038] 1 H NMR (400 MHz, CDCl3): δ 7.75-7.73 (m, 2H), 7.19-7.17 (m, 2H),7.03-7.01 (m, 2H), 6.89-6.85 (m, 1H), 4.57 (s, 2H), 2.37 (s, 3H), 2.11 (s, 6H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com