Graphene aqueous solution and preparation method thereof

A technology of graphene aqueous solution and graphite, which is applied in the field of graphene aqueous solution and its preparation, can solve the problems of unstable graphene aqueous dispersion, performance degradation, etc., achieve good intrinsic structure, maintain intrinsic structure, and be environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The graphene aqueous solution of this embodiment is prepared by the following method:

[0055] (1) Take graphene and potassium hydroxide raw materials of corresponding quality in the ratio of 1:6 with graphene: potassium hydroxide mass ratio;

[0056] (2) After mixing the above raw materials, add them to the agate ball mill jar, and install it on a planetary ball mill at a speed of 300 rpm, and mill for 48 h;

[0057] (3) Use deionized water to transfer the product after ball milling, and perform centrifugation at a speed of 3000 rpm for 10 minutes, and take the upper layer solution after the end;

[0058] (4) The obtained solution was dialyzed in deionized water for 48 h until the solution was neutral;

[0059] (5) The obtained product was subjected to ultrasonic treatment for 3 h, and the ultrasonic frequency was set to 50 Hz, and finally the desired graphene aqueous solution was obtained.

Embodiment 2

[0061] The graphene aqueous solution of this embodiment is prepared by the following method:

[0062] (1) Take graphene and potassium hydroxide raw materials of corresponding quality in the ratio of 1:10 with graphene: potassium hydroxide mass ratio;

[0063] (2) After mixing the above raw materials, add them to the agate ball mill jar, and install it on a planetary ball mill at a speed of 300 rpm, and mill for 48 h;

[0064] (3) Use deionized water to transfer the product after ball milling, and perform centrifugation at a speed of 3000 rpm for 10 minutes, and take the upper layer solution after the end;

[0065] (4) The obtained solution was dialyzed in deionized water for 48 h until the solution was neutral;

[0066] (5) The obtained product was subjected to ultrasonic treatment for 3 h, and the ultrasonic frequency was set to 50 Hz, and finally the desired graphene aqueous solution was obtained.

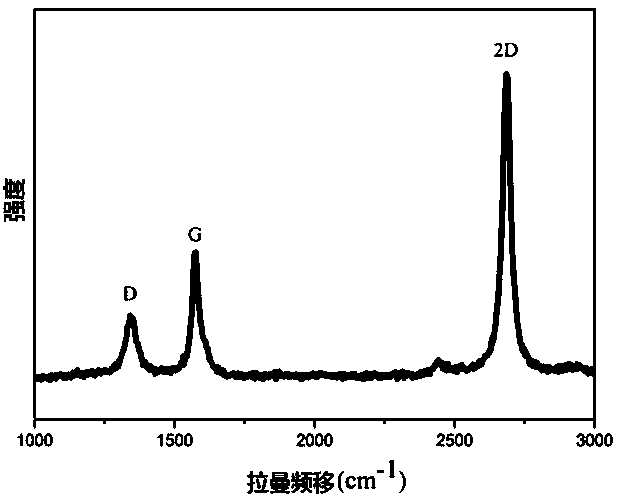

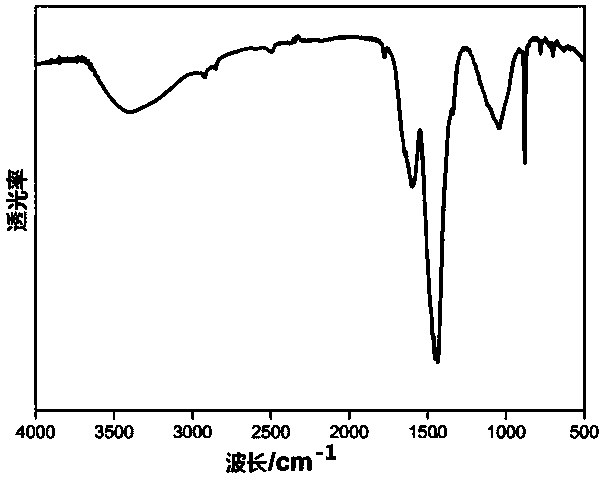

[0067] The characterization test of the present embodiment graphene aqueou...

Embodiment 3

[0069] The graphene aqueous solution of this embodiment is prepared by the following method:

[0070] (1) Take graphene and potassium acetate raw materials of corresponding quality in the ratio of 1:10 with graphene: potassium hydroxide mass ratio;

[0071] (2) After mixing the above raw materials, add them to the agate ball mill jar, and install it on a planetary ball mill at a speed of 500 rpm, and mill for 48 h;

[0072] (3) Use deionized water to transfer the product after ball milling, and perform centrifugation at a speed of 3000 rpm for 10 minutes, and take the upper layer solution after the end;

[0073] (4) The obtained solution was dialyzed in deionized water for 48 h until the solution was neutral;

[0074] (5) The obtained product was subjected to ultrasonic treatment for 3 h, and the ultrasonic frequency was set to 50 Hz, and finally the desired graphene aqueous solution was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com