Double-sided progressive double brake system

A braking system, a progressive technology, applied in the field of braking, can solve the problems of reducing the braking performance of the car, shortening the replacement time of the brake pads, and lack of driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

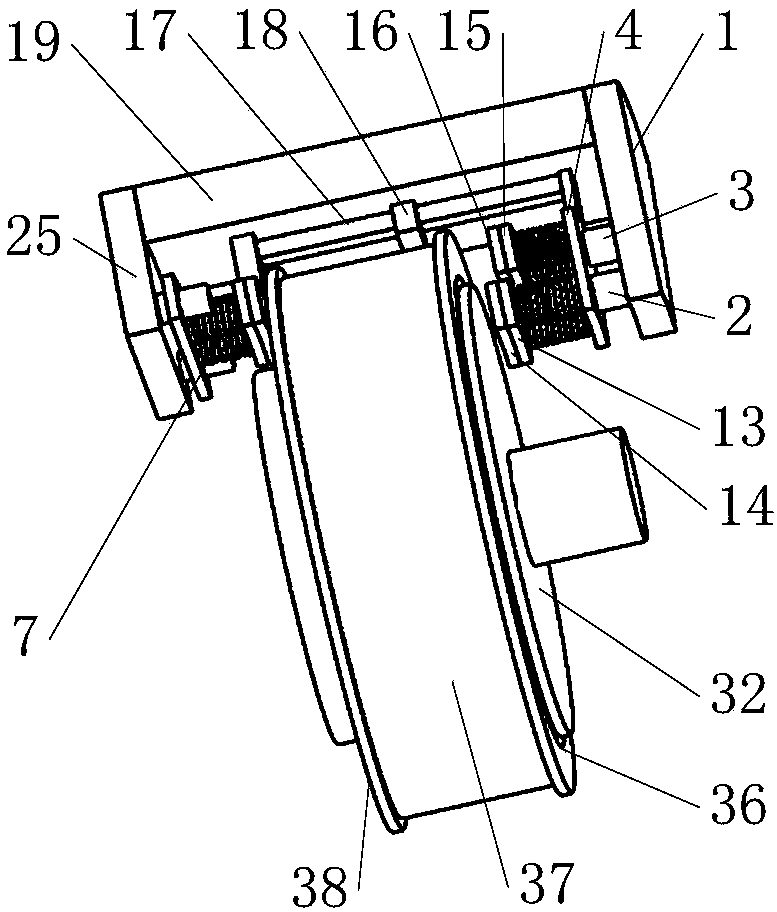

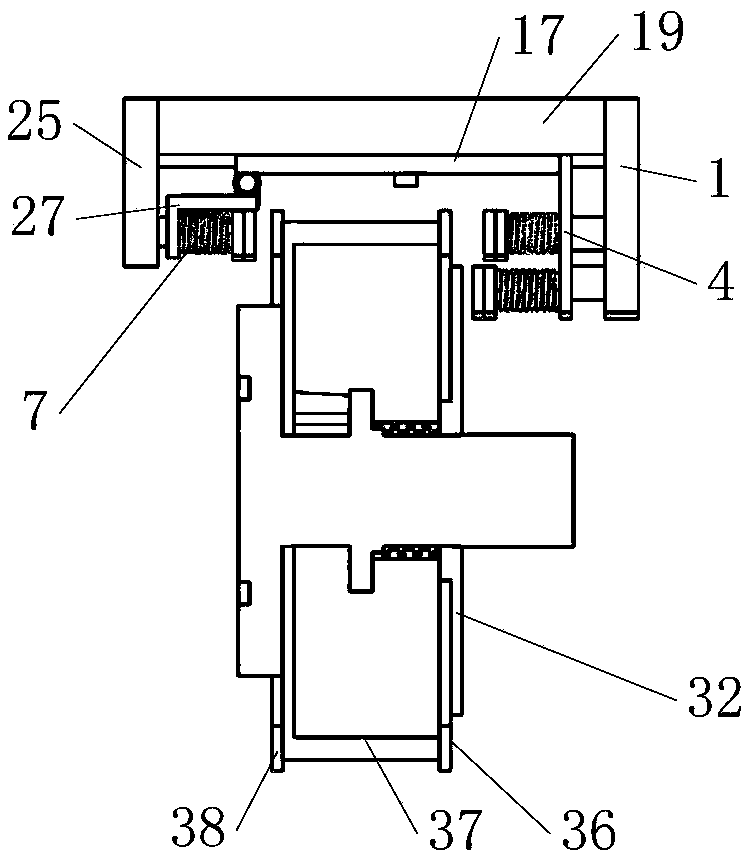

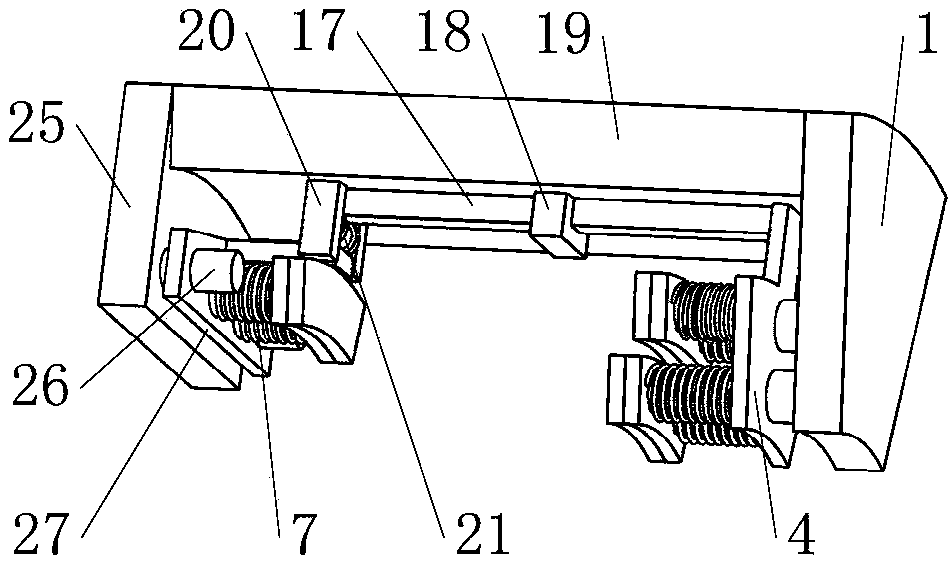

[0075] Specific embodiments: when the first hydraulic power column 2 and the second hydraulic power column 3 are not stretched by the hydraulic system, the first brake pad 14 and the first brake disc 32 do not contact and cause friction, and there is no braking effect at this time.

[0076] When the hydraulic system controls the extension of the first hydraulic power column 2 and the second hydraulic power column 3, the first hydraulic power column 2 and the second hydraulic power column 3 simultaneously push the first power plate 4, the first expansion rod 9, the second The telescopic rod 10, the first buffer spring 5, the second buffer spring 6, the first brake pad support 13, the first brake pad 14, the second brake pad support 15 and the second brake pad 16 move toward the first brake disc 32 together , at the same time, the first rack 17 moves in the same direction under the drive of the first power plate 4; the first rack 17 drives the first gear mechanism 21 to rotate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com