Welding seam trajectory offline calibration method based on structured light visual sensor

A vision sensor and calibration method technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of no matching calibration and achieve good track calibration and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

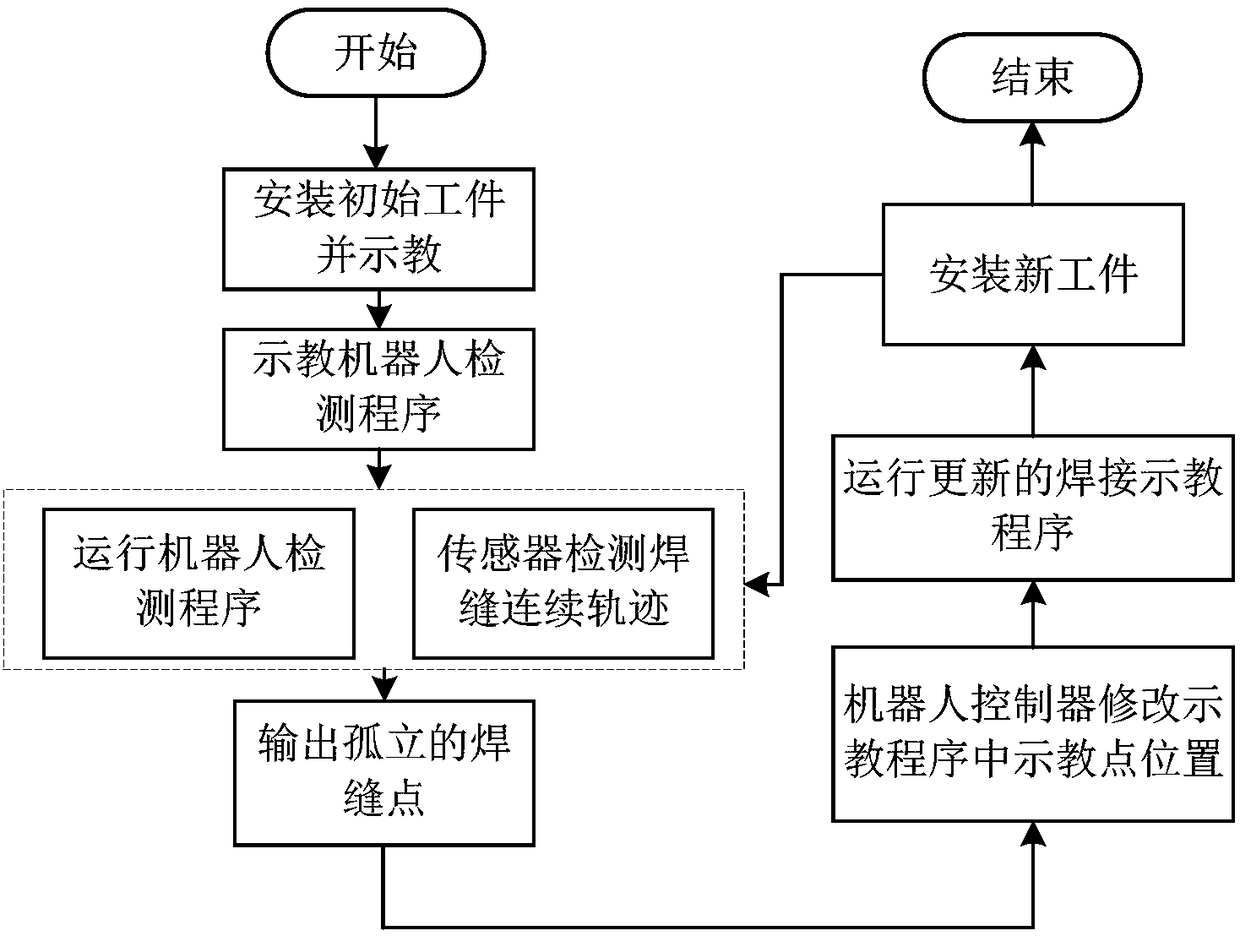

[0045] Such as figure 1 As shown, an off-line calibration method of weld trajectory based on structured light vision sensor, including steps:

[0046] Step 1. Teach the initial workpiece, and obtain the teaching track and teaching point of the initial workpiece;

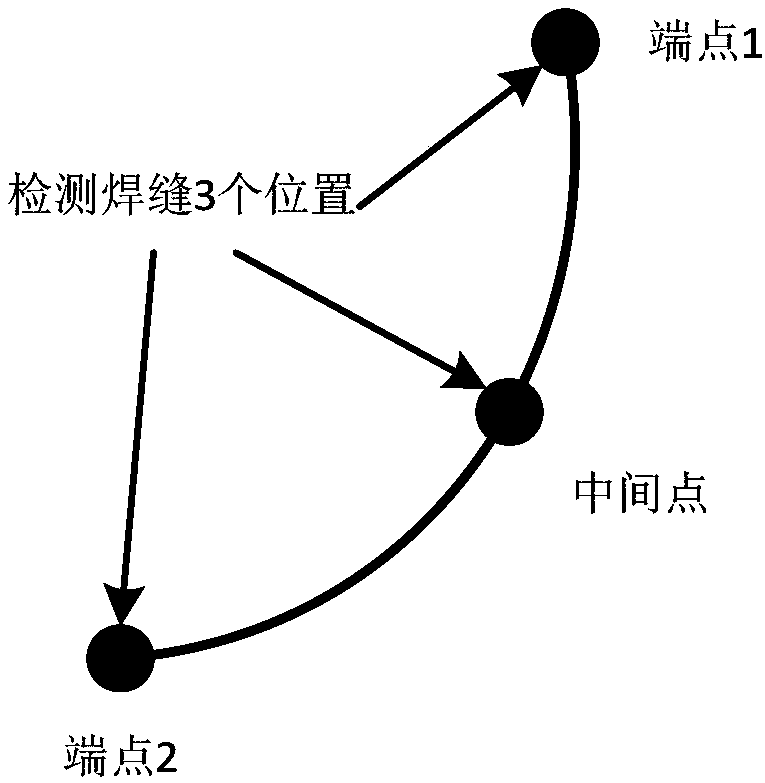

[0047] Step 2. When the form of the weld is a simple regular weld, according to the structural form of the weld, select a number of specific weld point positions that can reflect the form of the weld; teach the robot detection program to ensure that the structured light vision sensor can detect all Selected specific weld point locations;

[0048] Step 3, run the welding seam detection program, the robot moves to the position of each selected specific welding seam point, and the structured light vision sensor detects the position information of each specific welding seam point of the current laser line;

[0049] Step 4, extracting the position information of each detected specific welding seam point, and transmittin...

Embodiment 2

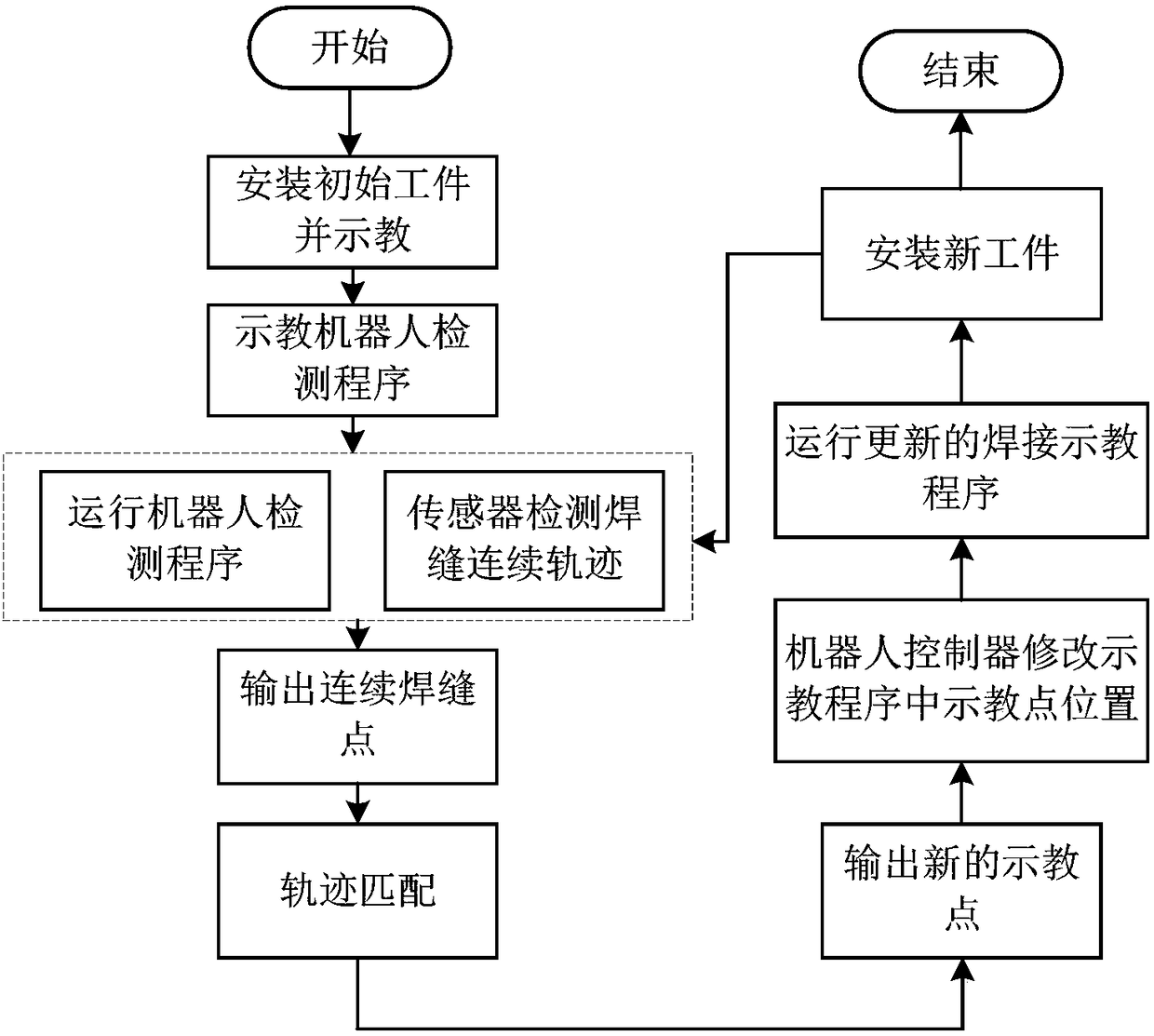

[0055] Such as image 3 As shown, an off-line calibration method of weld trajectory based on structured light vision sensor, including steps:

[0056] Step 1. Teach the initial workpiece, and obtain the teaching track and teaching point of the initial workpiece;

[0057] Step 2. When the weld seam is an irregular and complex weld seam, according to the structural form of the workpiece weld seam, teach the robot weld seam inspection program, so that the structured light vision sensor can detect the continuous trajectory of the entire weld seam;

[0058] Step 3. Run the welding seam inspection program, the robot starts to continuously inspect the entire welding seam of the workpiece from the starting position, and obtains the continuous trajectory points of the welding seam;

[0059] Step 4. Transmit the detected corresponding weld point position information to the robot controller to modify the teaching point position in the initial teaching program, specifically including:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com