Movable cross beam locking device of gantry five-axis machine

A locking device and five-axis machine technology, which are applied to metal processing machinery parts, large fixed members, metal processing equipment, etc. Accuracy, improve processing efficiency, reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

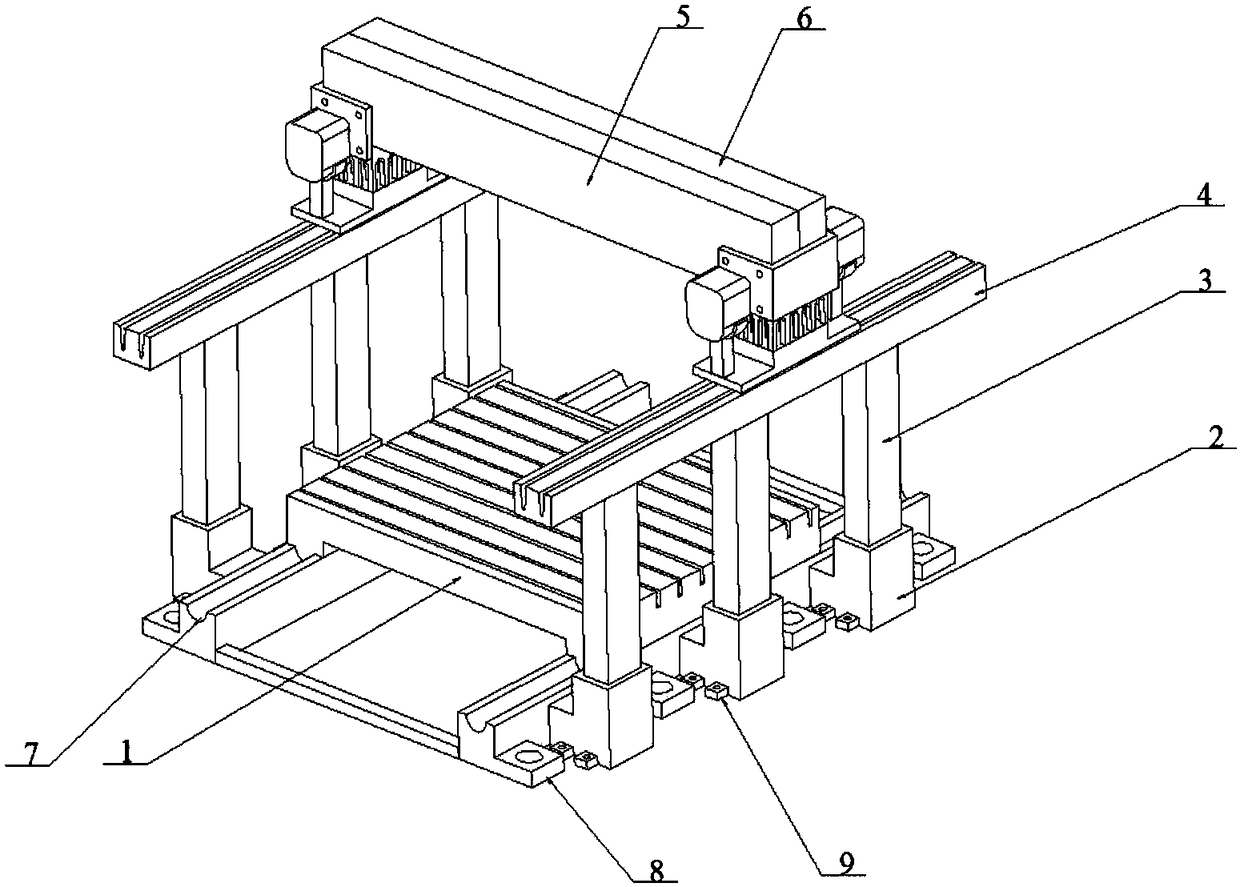

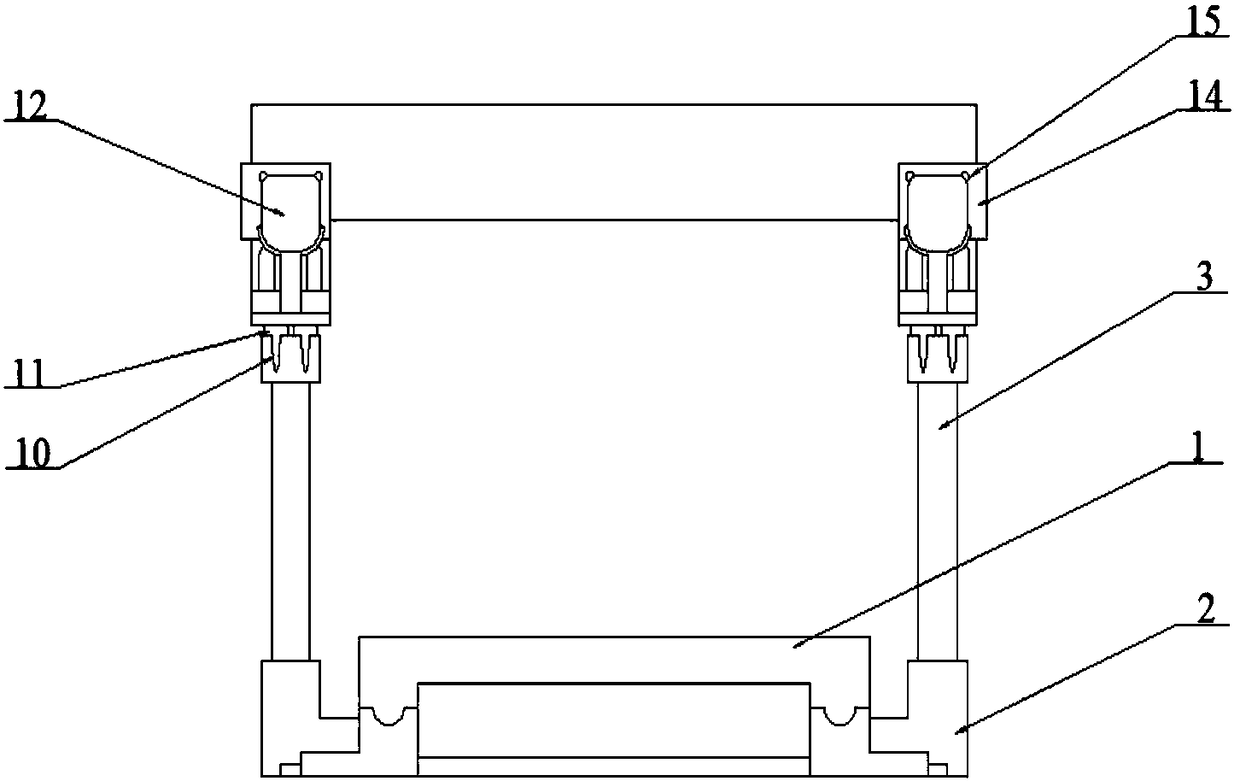

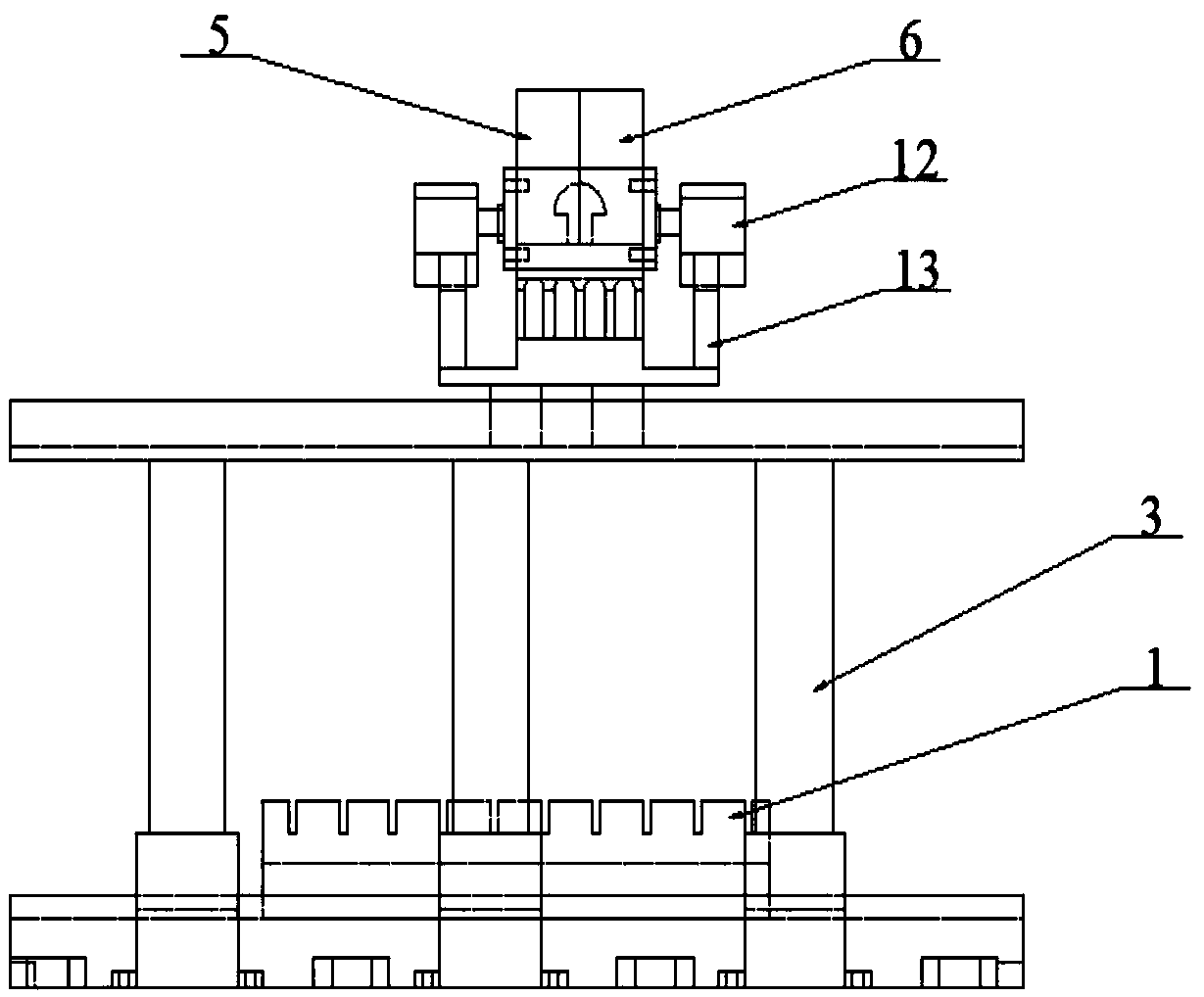

[0036] See Figure 1-9 , The moving beam locking device of the gantry five-axis machine of the present invention includes a workbench 1, a base 2, a column 3, a second guide rail 4, a beam I5, a beam II6, a first guide rail 7, a large foot iron 8, and a small foot Iron 9, chute 10, sliding block 11, hydraulic cylinder 12, bracket 13, locking pressure plate 14, bolt hole I 15, support seat 16, connecting block 17, arched door post 18, bolt hole II 19, anchor connection structure 20 , Piston rod 21, inner groove 22, bolt hole III23.

[0037] The workbench 1 slides on the first guide rail 7. A number of big foot irons 8 are arranged on the sides of the two first guide rails 7, and the first guide rail 7 is fixed on the ground by the big foot irons 8, and is arranged on the side 7 of each first guide rail. Several bases 2, two small foot irons 8 are set on the sides of the base 2, and the base 2 is fixed on the ground by the small foot irons 8. The upper end of each base 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com