Processing method of organic composite tea in bags

A processing method and compound bag technology are applied in the field of using organic raw materials to produce compound tea bags, which can solve the problems of not being suitable for consumption, foreign consumers do not like pure tea beverages, etc., and achieve a pleasant aroma, harmonious taste, and convenient drinking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

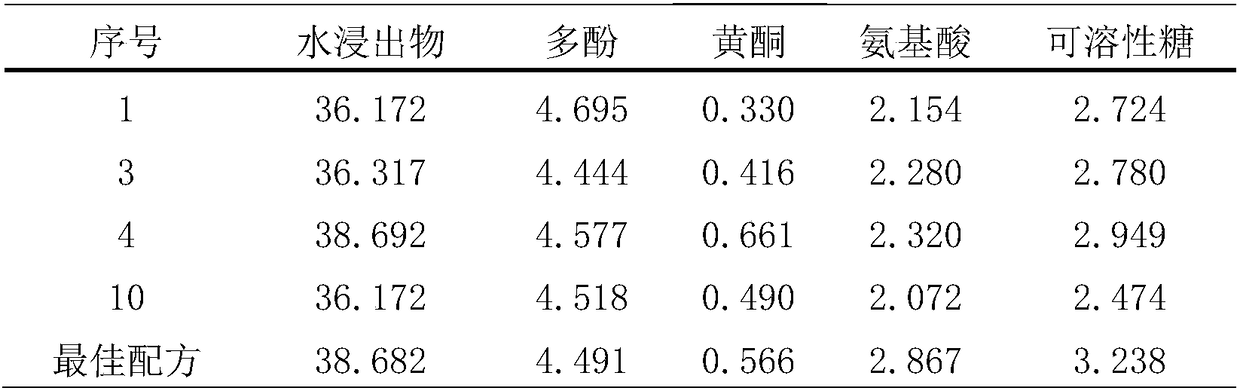

Embodiment 1

[0033] The crushed samples of each raw material crushed during the preliminary research of the test were selected, according to A hawthorn 4.8g, B dandelion root 5.2g, C black tea 9.8g, D mint leaves 6.2g, E cumin 3.1g, F tangerine peel 4.2g, G Chamomile 4.2g. The aroma score is 96.0, the taste score is 96.0, and the average is 96.0 points; the contents of water extract, tea polyphenols, flavonoids, amino acids and soluble sugars are 38.601%, 4.512%, 0.521%, 2.844% and 3.226%, respectively.

Embodiment 2

[0035] Select the crushed samples of each raw material crushed during the preliminary research of the test, according to A hawthorn 5.0g, B dandelion root 4.8g, C black tea 10.5g, D mint leaves 6.0g, E cumin 2.9g, F tangerine peel 3.8g, G Chamomile 3.8g. The aroma score was 95.0, the taste score was 97.0, and the average score was 96.0; the contents of water extract, tea polyphenols, flavonoids, amino acids and soluble sugars were 38.625%, 4.504%, 0.514%, 2.850% and 3.216%, respectively. .

Embodiment 3

[0037] Select the crushed samples of each raw material crushed during the preliminary research of the test, according to A hawthorn 5.1g, B dandelion root 4.8g, C black tea 9.5g, D mint leaves 5.8g, E cumin 3.0g, F tangerine peel 4.0g, G Chamomile 4.0g. The aroma score is 96.0, the taste score is 96.0, and the average is 96.0 points; the contents of water extract, tea polyphenols, flavonoids, amino acids and soluble sugars are 38.616%, 4.491%, 0.556%, 2.861% and 3.222%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com