High-flux continuous flow analysis method for water-soluble sugar in tobacco gene editing material

A gene editing, water-soluble sugar technology, applied in the field of tobacco chemistry research, can solve problems such as inconvenience, affect the efficiency of detection work, affect the reliability of detection results, etc., to speed up the process, improve the efficiency of sample analysis, and simplify the sample pretreatment process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

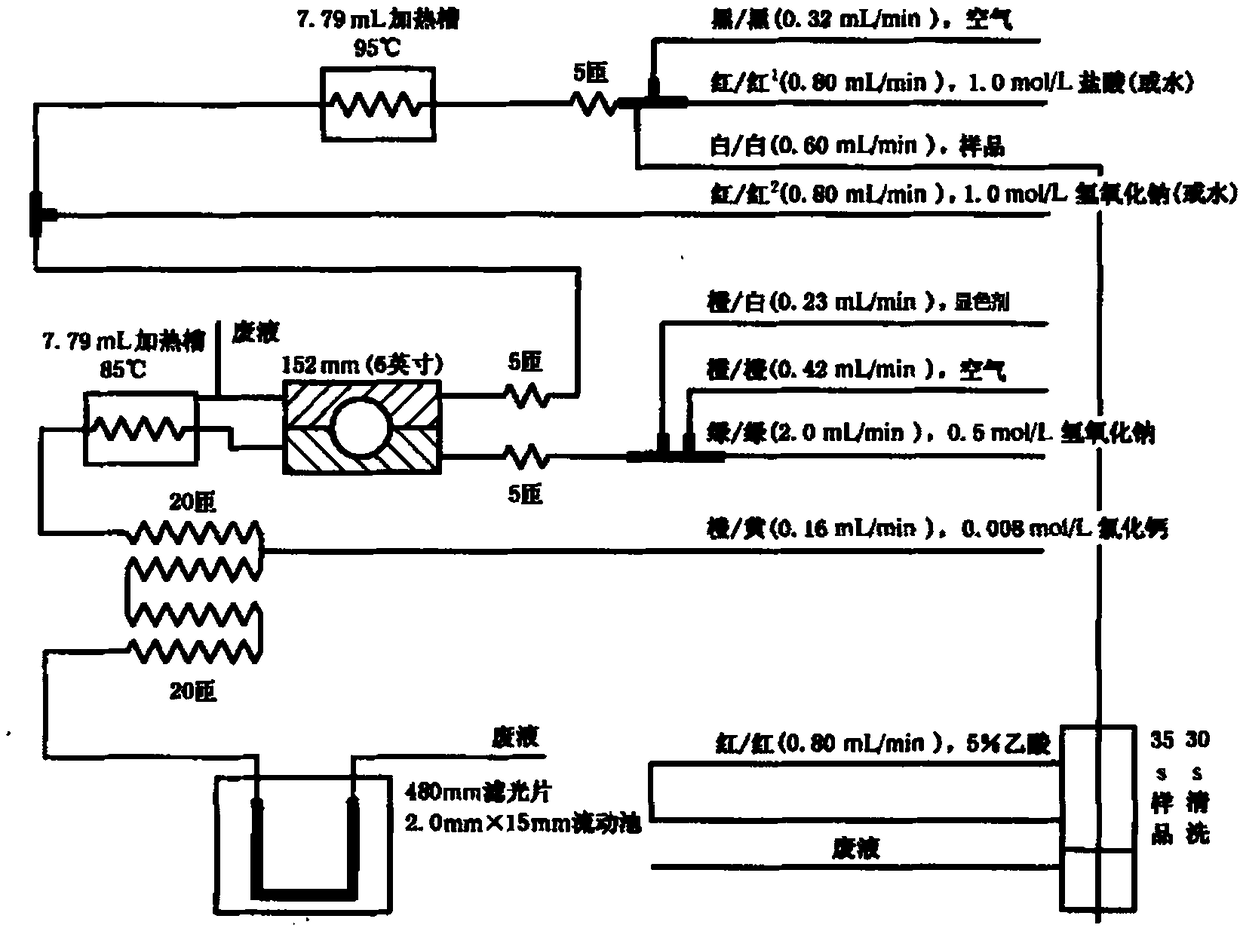

[0031] Embodiment 1: Determination of total sugar in flue-cured tobacco sample

[0032] 1) Sample pretreatment: firstly dry the tobacco leaves (or shredded tobacco), use a high-speed cyclone mill to break the cell walls of tobacco and tobacco products, then pass through a 60-mesh sieve, seal and store as a sample preparation. Test the water content of the sample according to the YC / T31-1996 standard, and then handle it as follows:

[0033] A. Accurately weigh 0.25g of sample into a 25mL improved sample tube, remove the sample tray from the automatic sampler of the continuous flow analyzer, and fill the sample tube with the weighed sample in order to inject into the continuous flow analyzer 100 sampling tube positions on the tray;

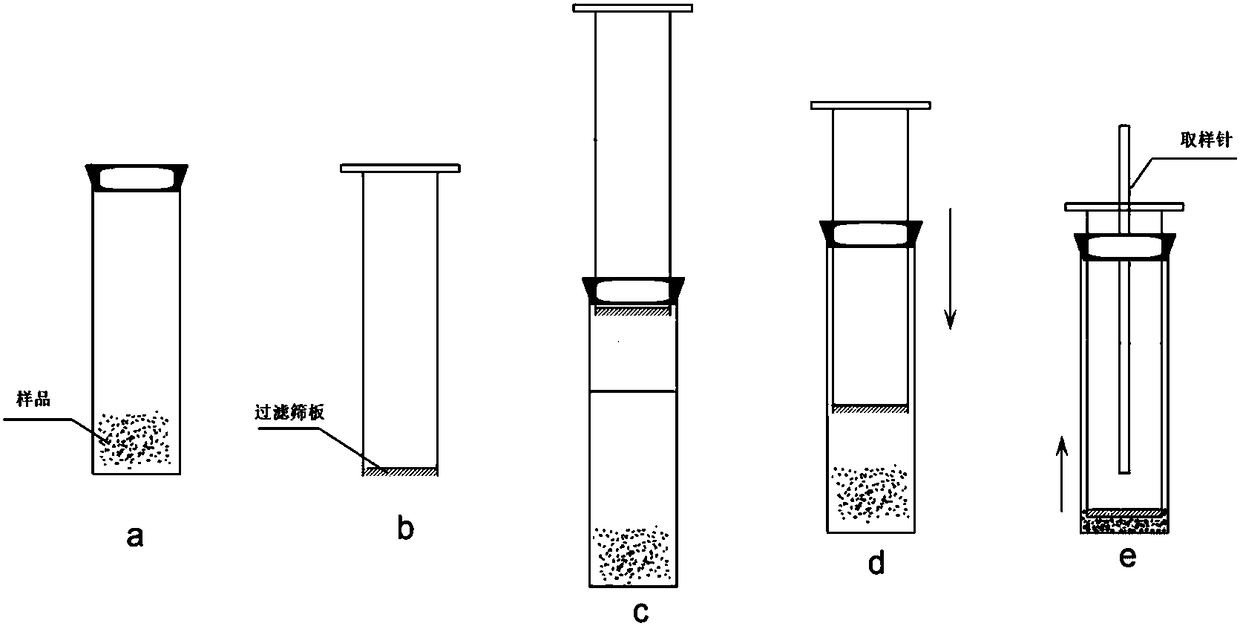

[0034] B. Use a 25mL pipette gun to add 25mL of 5% acetic acid solution to each sample tube, and then insert the inner casing of the filter sieve plate with a pore size of 0.45 μm at the bottom to prevent the solution from splashing during the vibr...

Embodiment 2

[0039] Embodiment 2: Determination of reducing sugar in flue-cured tobacco sample

[0040] Repeat the process in Example 1 to measure the reducing sugar in the flue-cured tobacco sample, and the measured reducing sugar content is 20.52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com