Light wave wall-hanging stove

A wall-hung furnace and light wave technology, applied in lighting and heating equipment, fluid heaters, water heaters, etc., can solve problems such as electric shock accidents, electric leakage, and pipe bursts, so as to achieve safe and reliable use and avoid electric shock accidents , the effect of wide heat radiation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

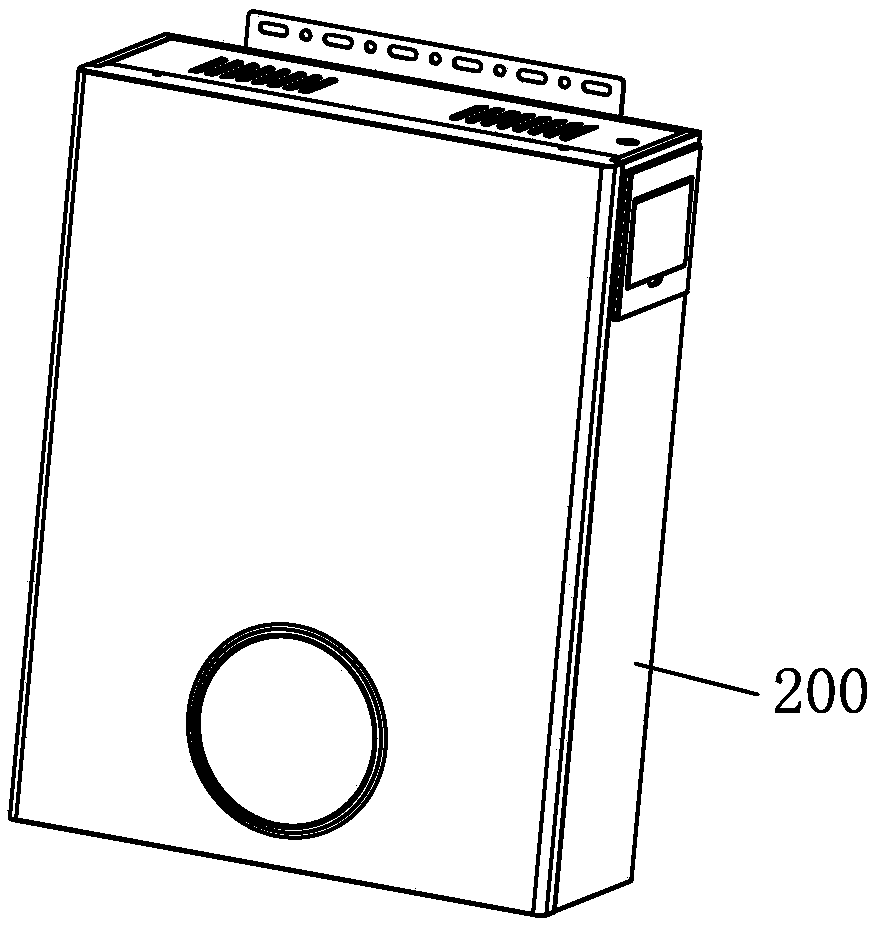

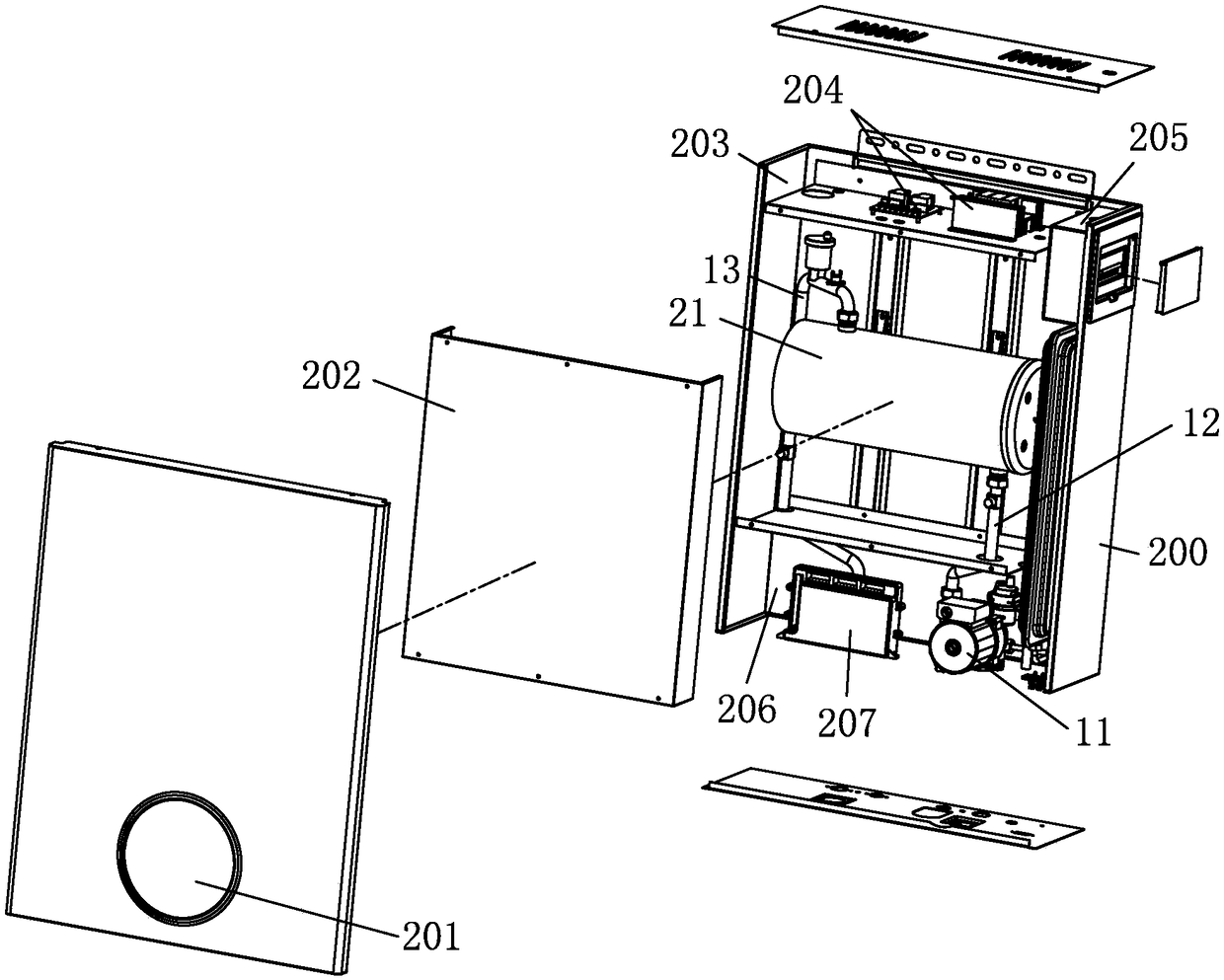

[0029] see Figure 1-Figure 7 , the light-wave wall-hung boiler includes a furnace body 200, the furnace body 200 is provided with a water inlet valve 10, a circulation pump 11, a water inlet pipe 12, an electric heating water tank, an outlet pipe 13 and a water outlet valve 14, which are sequentially connected to form a heating water circuit, When the present invention is working, tap water or heating water enters the electric heating water tank from the water inlet valve 10 and the water inlet pipe 12 under the action of the circulating pump 11, and is output to the water terminal through the water outlet pipe 13 and the water outlet valve 14 after passing through the electric heating water tank. or on the heating end.

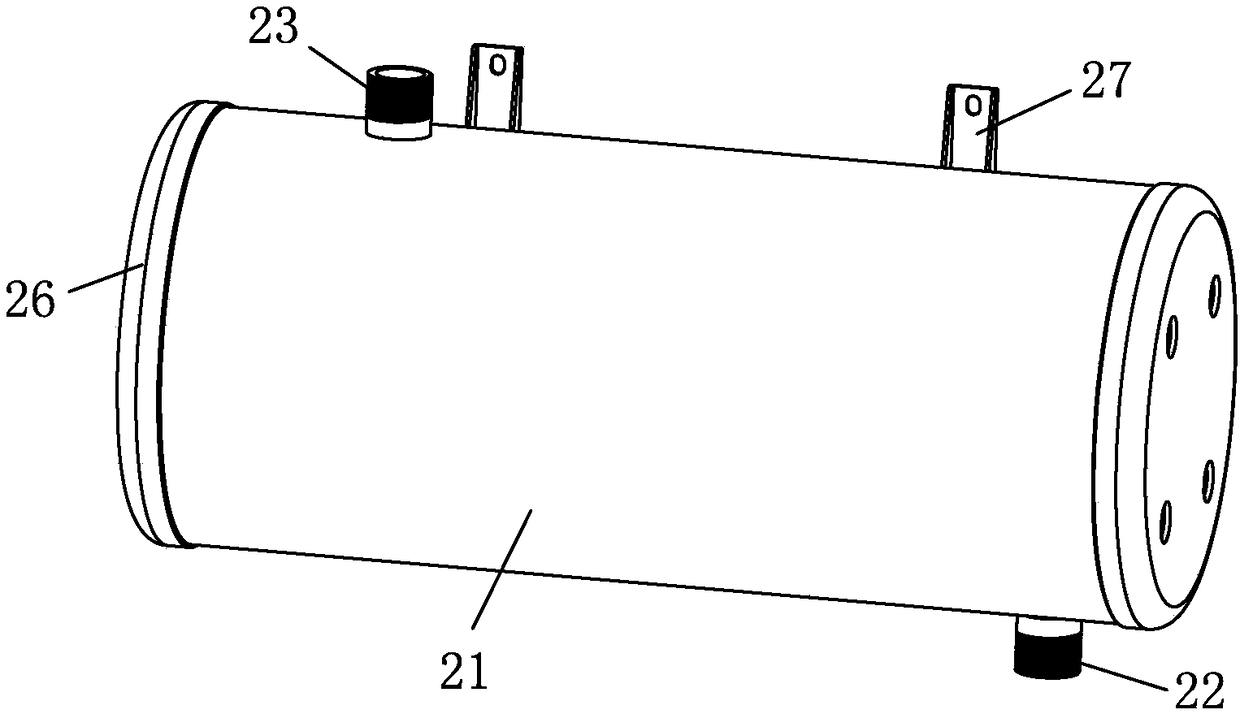

[0030] Wherein, the heating water tank of this embodiment is improved as follows, the heating chamber 25 is formed inside the heating box 21 for water circulation and heating; The water outlet 23 connected with the heating chamber 25 and the water outlet pi...

no. 2 example

[0041] The main difference between this heating water tank and the first embodiment is that there is one heating cylinder 24 installed in the heating box 21, which is arranged on the central axis of the heating box 21, and one set of light wave heating tubes is arranged in one heating cylinder 24 28, its actual heating power is relatively smaller, and this technical solution is more suitable for the household field.

[0042] Other unmentioned parts are the same as the first embodiment and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com