Automatic transferring system and method for muck after manual pipe jacking

A technology of pipe jacking and dregs, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of increasing construction cost, delaying construction period, low efficiency of manual excavation and transfer, etc., and achieve the effect of improving efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

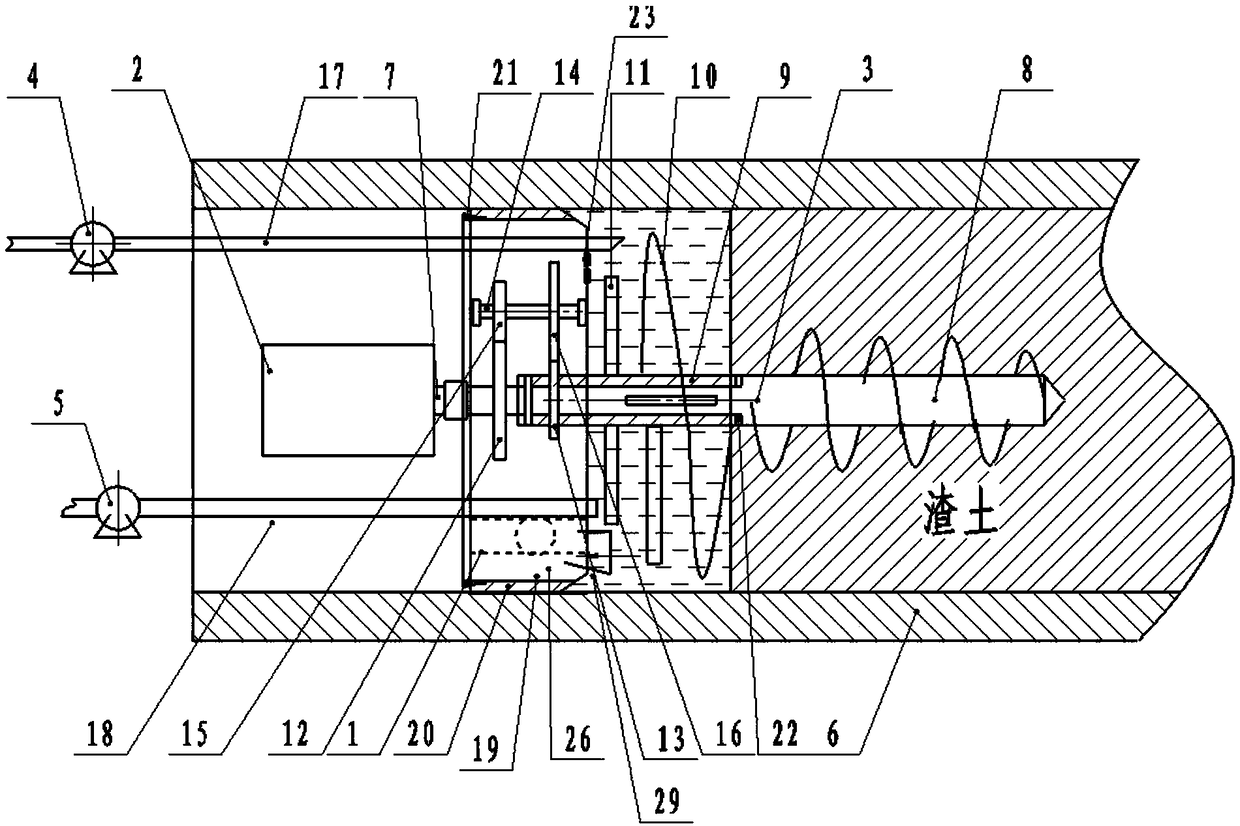

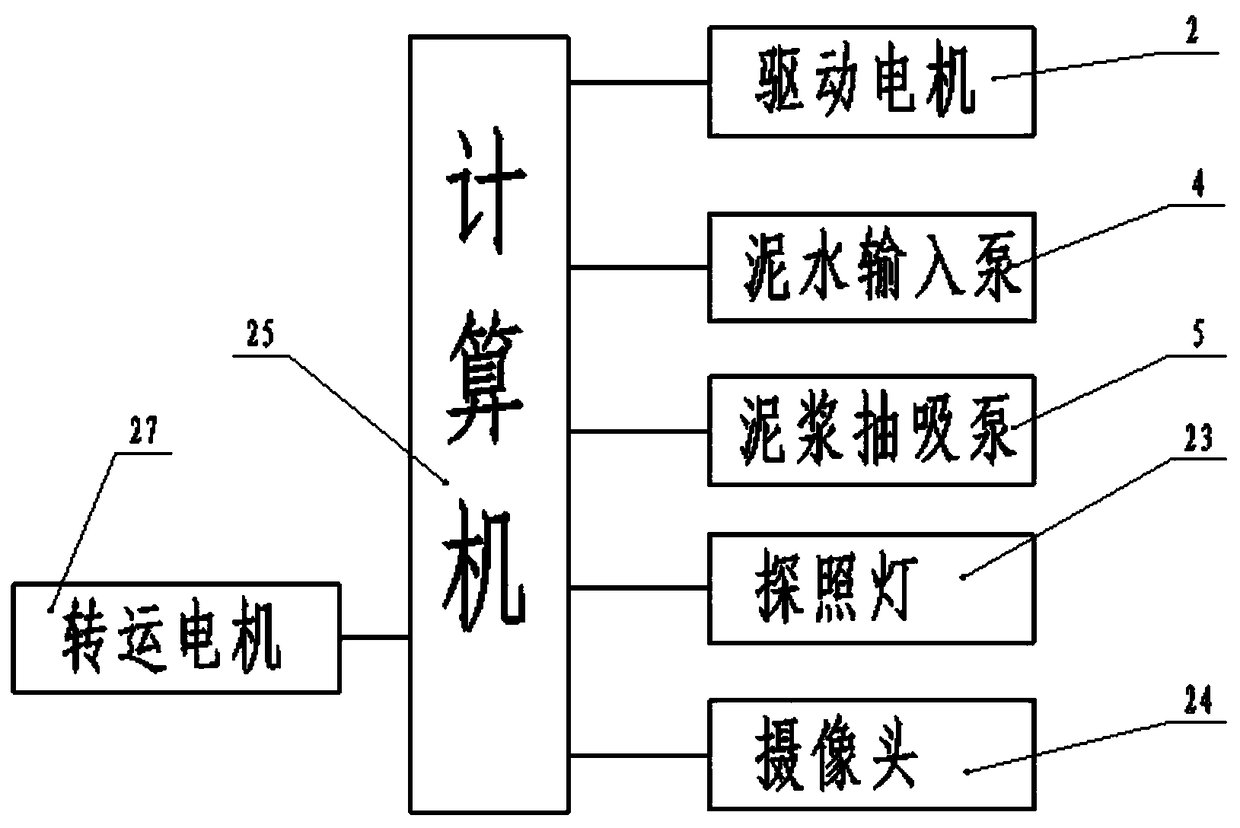

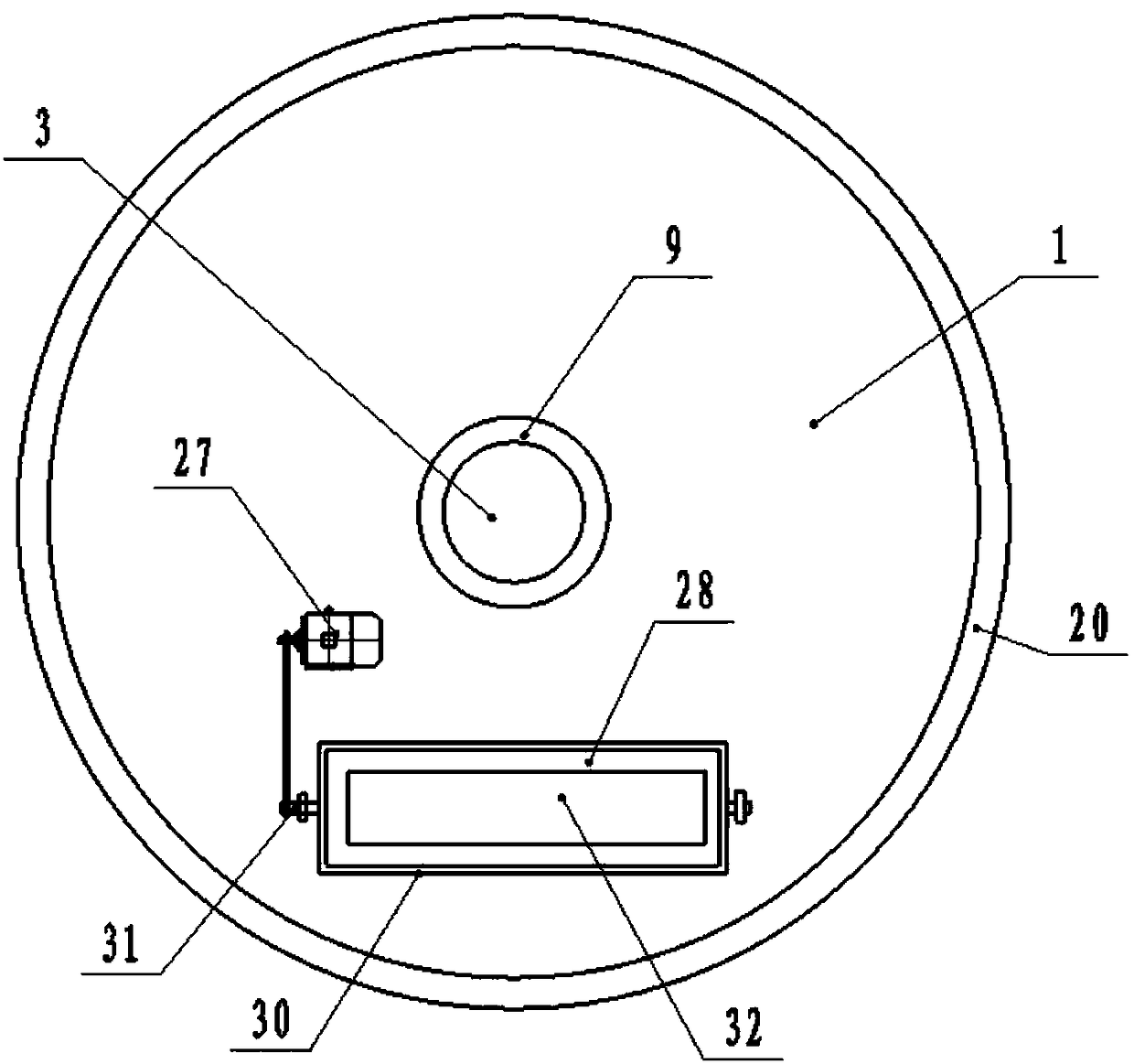

[0038] Such as Figure 1-3 As shown, the present invention is used for the automatic transfer system of slag after pipe jacking, comprising an annular sealing body 1, a driving motor 2, a rotating main shaft 3, a muddy water input pump 4 and a mud suction pump 5, and is characterized in that: the annular The sealing body 1 is placed in the jacking pipe, the ring surface of the annular sealing body 1 is sealed and connected with the inner wall of the jacking pipe 6, and a driving motor 2 is arranged on the outer middle part of the annular sealing body 1, and the outer end of the rotating main shaft 3 is sealed through the annular sealing body. The center of the body 1 is connected with the output shaft 7 of the drive motor 2, a feed drill bit 8 is provided on the inner end shaft of the rotating main shaft 3, and a rotating sleeve 9 is set in the middle of the rotating main shaft 3, and the rotating sleeve 9 The end is provided with soil loosening screw blade 10, and the rotatin...

Embodiment 2

[0054] Such as Figure 1-3 As shown, the present invention is used for the muck transfer method in the pipe after the underground artificial pipe jacking of the municipal environmental protection construction, including steps:

[0055] Step 1. Manually dig out the soil residue at the port of the jacking pipe 6, insert the annular sealing body 1 into the jacking pipe 6, the sealing rubber sleeve 20 of the annular sealing body 1 is sealed and bonded to the inner wall of the jacking pipe 6, and the front end of the annular sealing body 1 The feed drill bit 8 is inserted into the unexcavated soil in the pipe jacking 6;

[0056] Step 2: Start the drive motor 2, the muddy water input pump 4 and the mud suction pump 5 by controlling the computer 25;

[0057]Step 3: by rotating the feed drill bit 8 provided on the inner end shaft of the main shaft 3 to rotate in the soil residue, the annular sealing body 1 and the components arranged on the annular sealing body are driven to move for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com