A lifting and horizontal transfer machine

A technology of lifting level and transferring machine, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., to achieve stable work, reduce circuit complexity, and reduce the effect of motor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

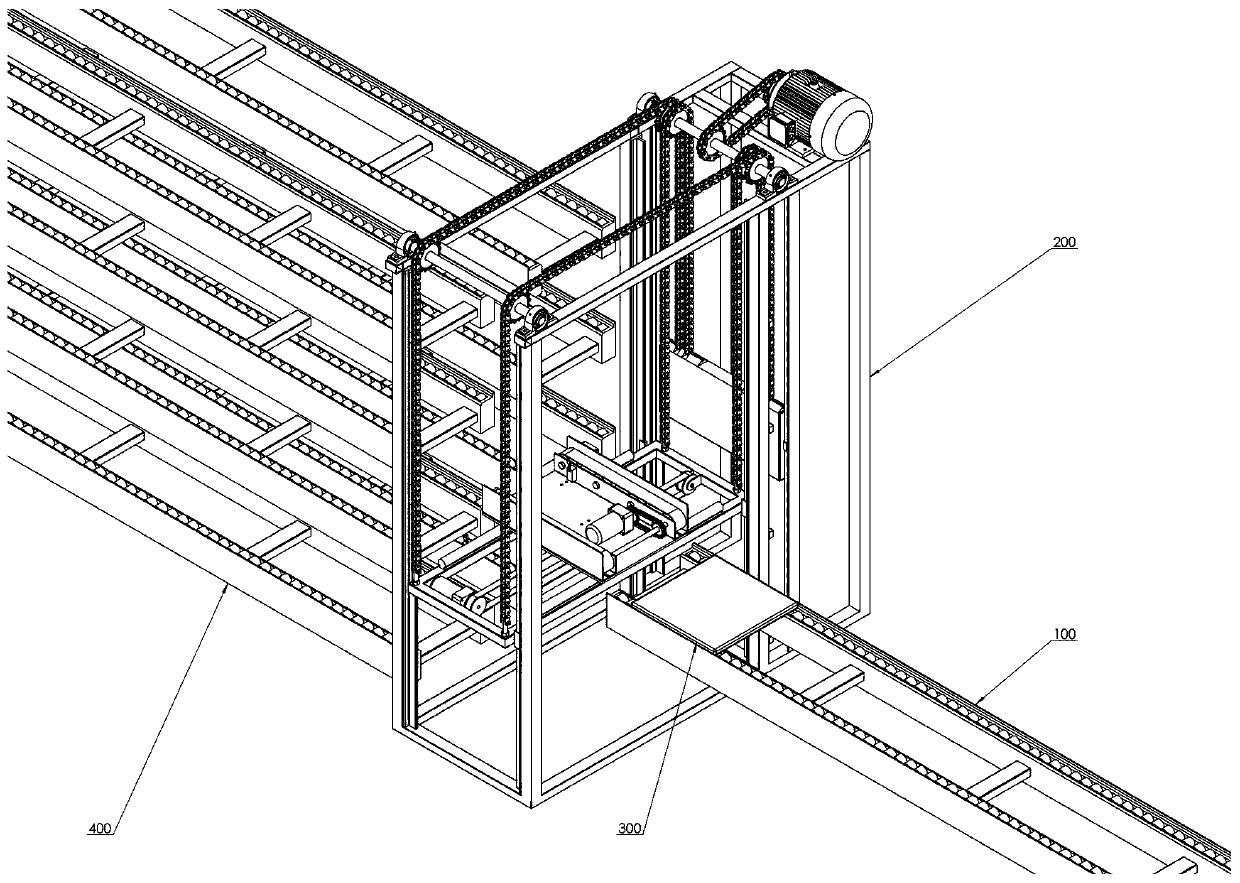

[0041] The application scenarios of the lifting and horizontal transfer machine provided by the embodiment of the present invention are as follows: figure 1 As shown, the lifting and horizontal transfer machine 200 provided by the present invention can effectively connect the single double-speed chain 100 at the entrance and exit of the aging room with the multi-layer double-speed chain 400 inside the aging room, and the tooling board 300 is conveyed by the single double-speed chain 100 .

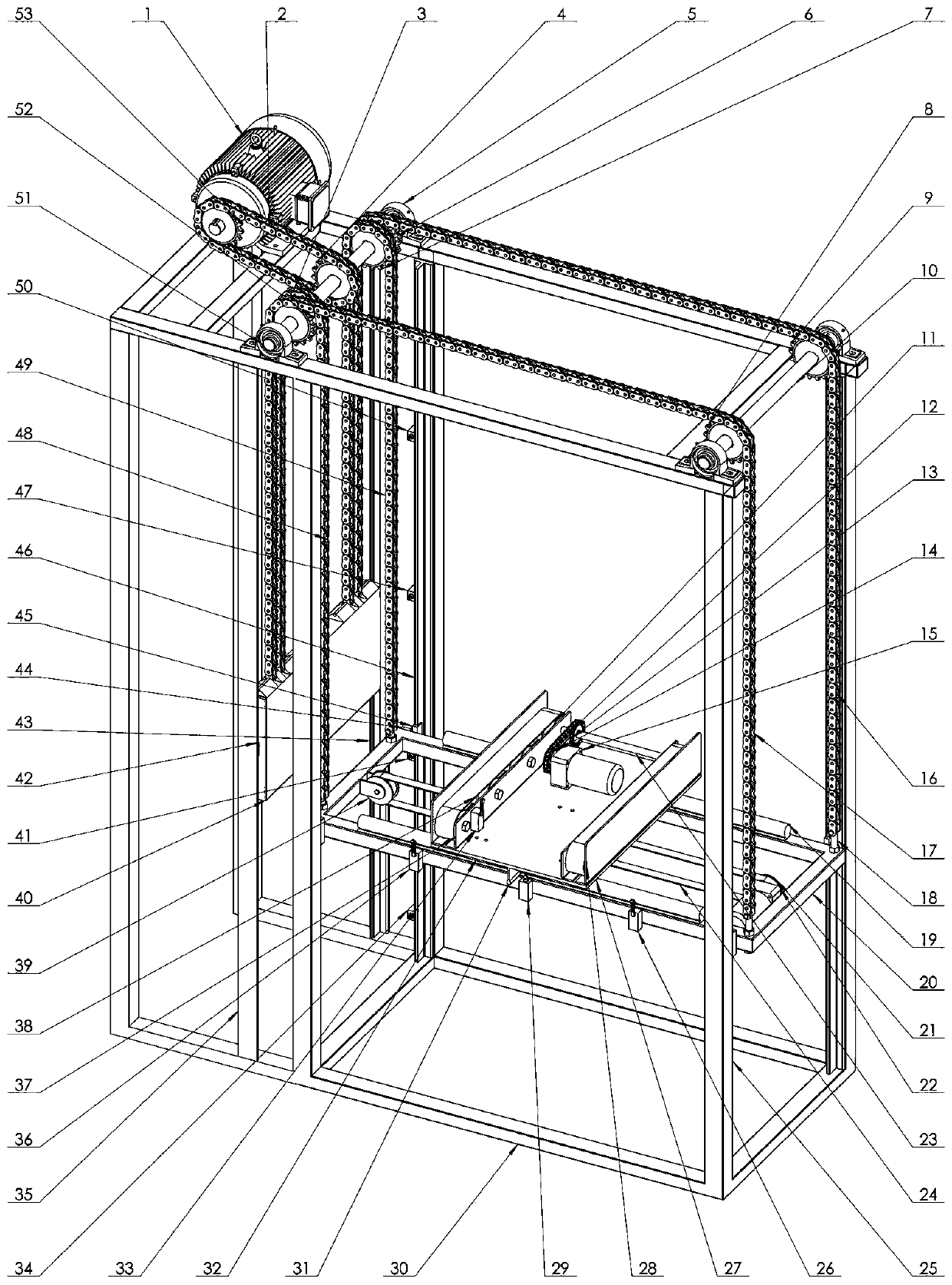

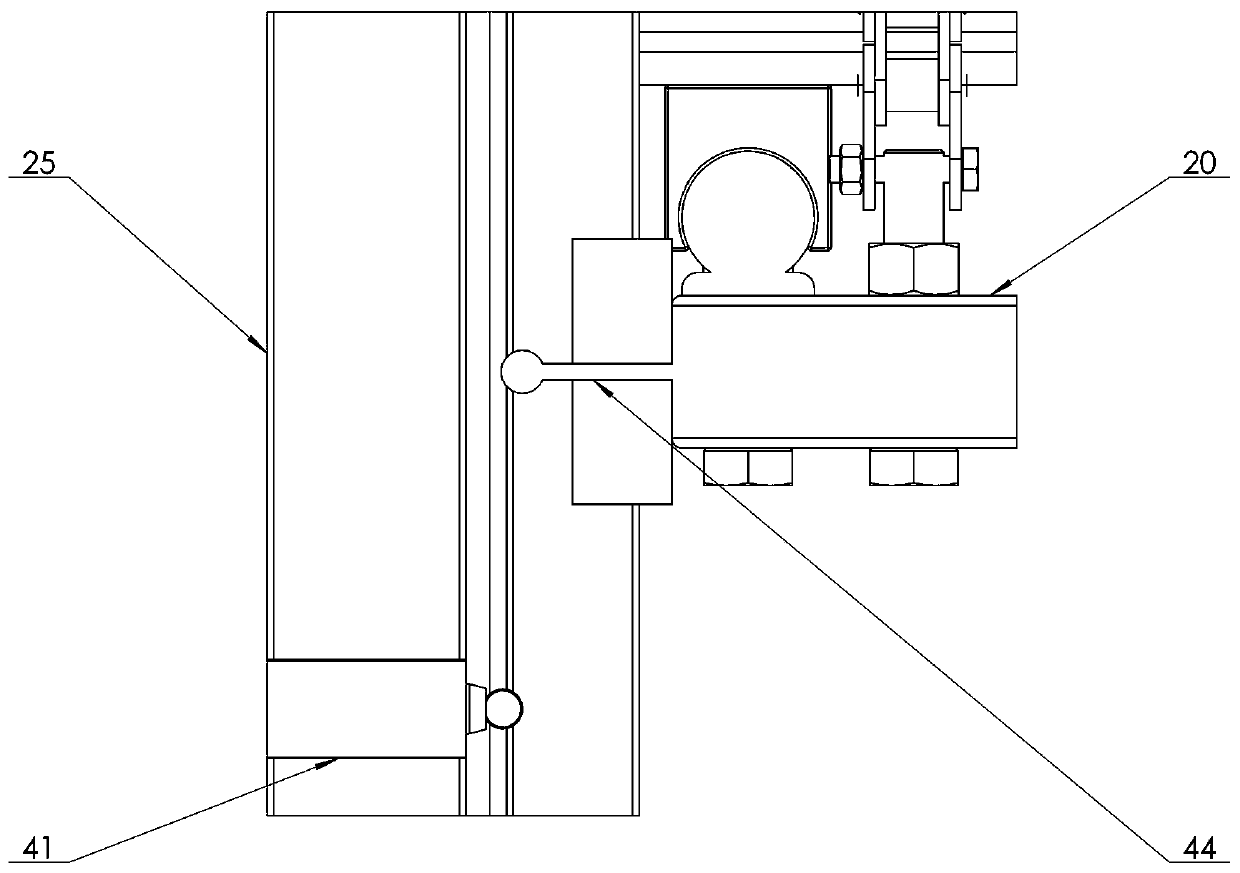

[0042] The structure of the lifting horizontal transfer machine provided by the embodiment of the present invention is as follows: figure 2 , image 3 , Figure 4 As shown, it includes a transfer machine support 30, a horizontal movement and a plate deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com