Plastic bag shredding equipment for plastic bag recycling

A technology of plastic bags and equipment, applied in the field of plastic bag shredding equipment for plastic bag recycling, can solve the problems of small cutting effect of plastic bags, complex structure, poor sanitation environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

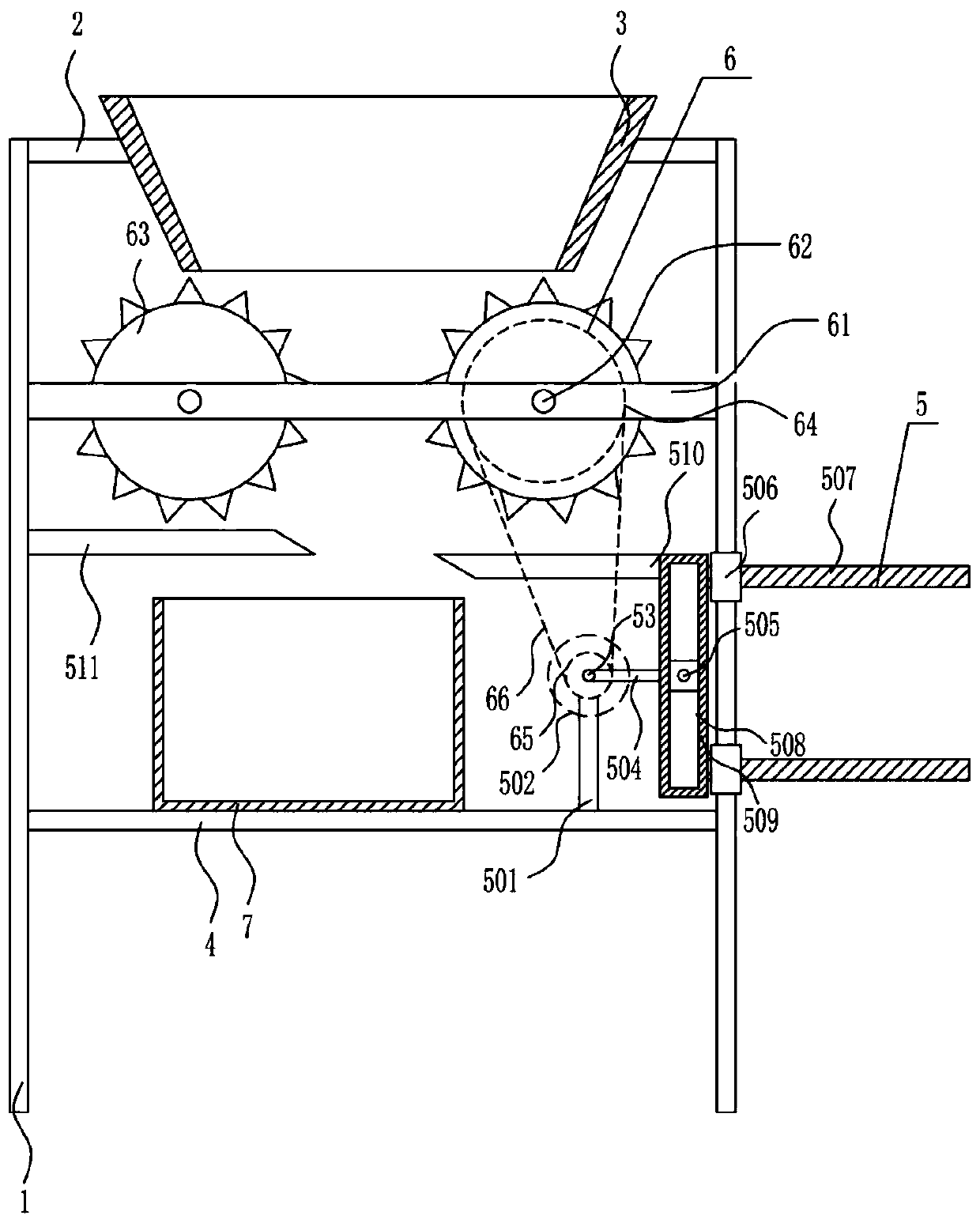

[0024] A plastic bag shredding equipment for plastic bag recycling, such as Figure 1-2 As shown, it includes a support leg 1, a first connecting rod 2, a hopper 3, a first placement plate 4, a cutting mechanism 5, a transmission mechanism 6 and a collection box 7, and the top between the left and right support legs 1 is connected with a first Connecting rod 2, the middle part of the first connecting rod 2 is provided with a guide hopper 3, the middle part between the left and right side legs 1 is connected with a first placement plate 4, a cutting mechanism 5 is installed on the first placement board 4, and a cutting mechanism 5 is installed on the support leg 1. A conveying mechanism 6 is installed, and a collection box 7 is arranged on the left side of the top of the first placement plate 4 .

Embodiment 2

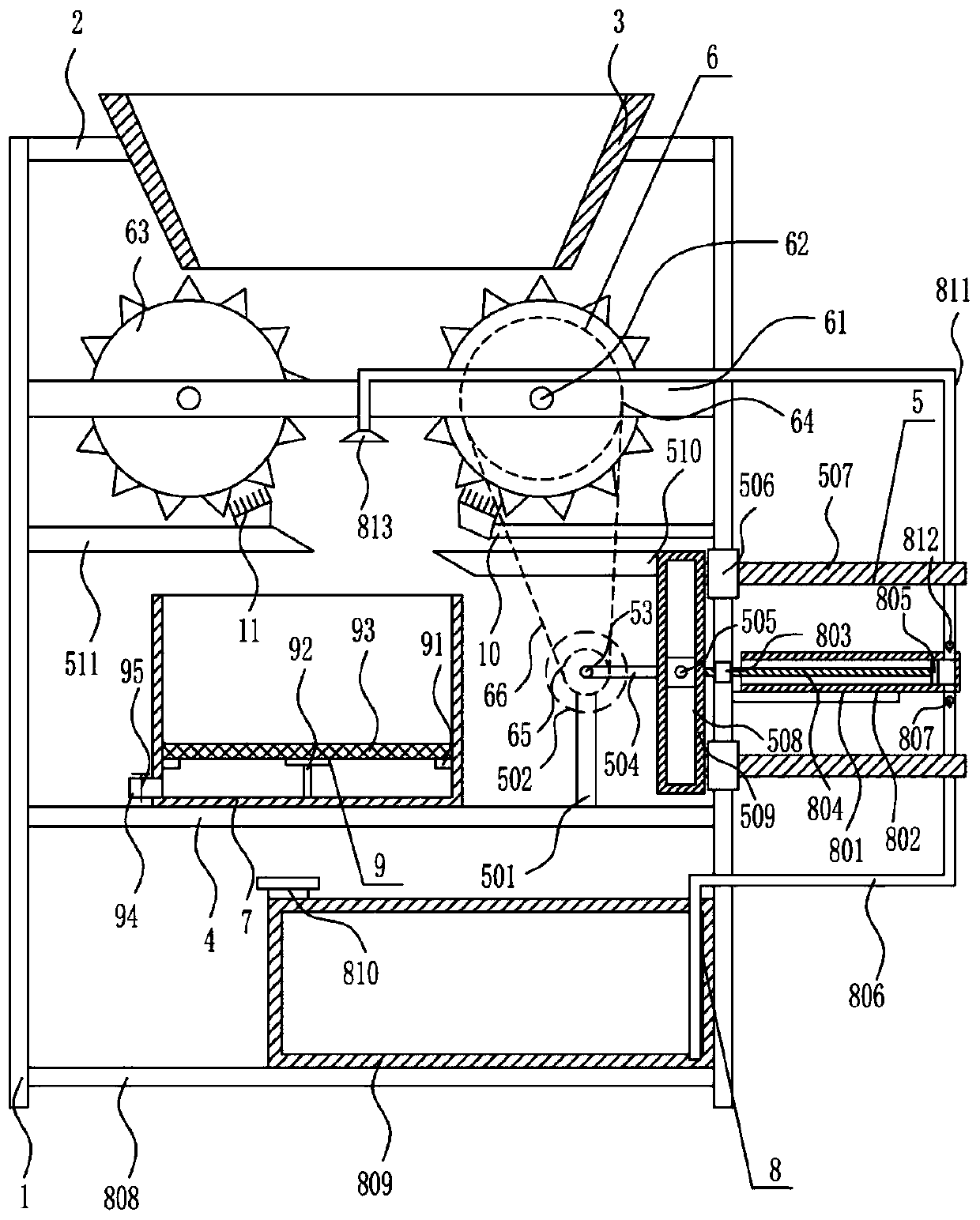

[0026] A plastic bag shredding equipment for plastic bag recycling, such as Figure 1-2 As shown, it includes a support leg 1, a first connecting rod 2, a hopper 3, a first placement plate 4, a cutting mechanism 5, a transmission mechanism 6 and a collection box 7, and the top between the left and right support legs 1 is connected with a first Connecting rod 2, the middle part of the first connecting rod 2 is provided with a guide hopper 3, the middle part between the left and right side legs 1 is connected with a first placement plate 4, a cutting mechanism 5 is installed on the first placement board 4, and a cutting mechanism 5 is installed on the support leg 1. A conveying mechanism 6 is installed, and a collection box 7 is arranged on the left side of the top of the first placement plate 4 .

[0027] The cutting mechanism 5 includes a first pole 501, a motor 502, a first rotating shaft 503, a second connecting rod 504, a slider 505, a first sliding sleeve 506, a first slid...

Embodiment 3

[0029] A plastic bag shredding equipment for plastic bag recycling, such as Figure 1-2 As shown, it includes a support leg 1, a first connecting rod 2, a hopper 3, a first placement plate 4, a cutting mechanism 5, a transmission mechanism 6 and a collection box 7, and the top between the left and right support legs 1 is connected with a first Connecting rod 2, the middle part of the first connecting rod 2 is provided with a guide hopper 3, the middle part between the left and right side legs 1 is connected with a first placement plate 4, a cutting mechanism 5 is installed on the first placement board 4, and a cutting mechanism 5 is installed on the support leg 1. A conveying mechanism 6 is installed, and a collection box 7 is arranged on the left side of the top of the first placement plate 4 .

[0030] The cutting mechanism 5 includes a first pole 501, a motor 502, a first rotating shaft 503, a second connecting rod 504, a slider 505, a first sliding sleeve 506, a first slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com