A method of laser welding explosion-proof sheet for aluminum shell battery cover plate

An aluminum shell battery and laser welding technology, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., to avoid welding explosion points and air leakage, avoid pollution, and improve welding yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

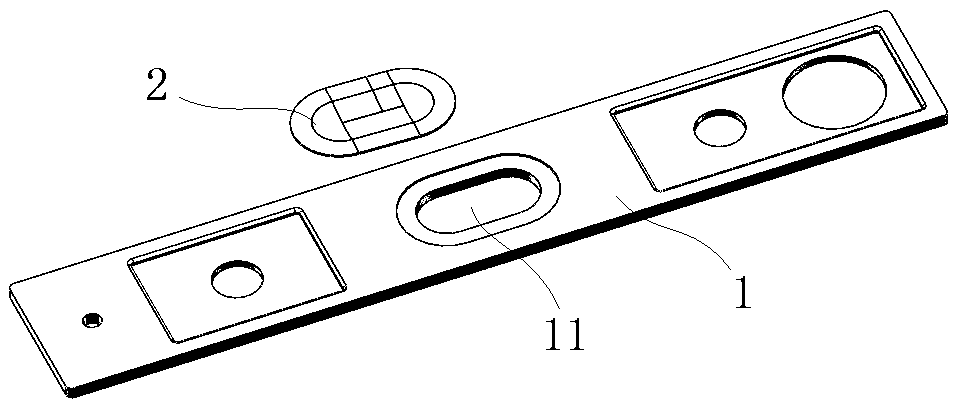

[0023] The present invention is a kind of laser welding method of explosion-proof plate of aluminum shell battery cover plate, referring to figure 1 , is to weld a piece of explosion-proof sheet 2 that can withstand a certain pressure on the cover plate 1 of the aluminum-cased battery. When there is no abnormal gas blowing, it is required that the explosion-proof disk cannot have an explosion point or an air leakage point. The laser welding method for the explosion-proof disk of the aluminum shell battery cover plate of the present invention includes the following method steps:

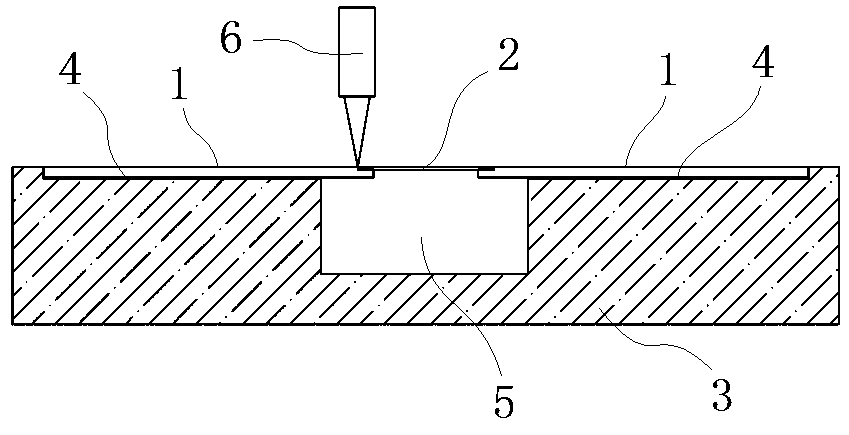

[0024] S1. Place the explosion-proof sheet on the pressure relief hole of the battery cover of the aluminum case, use a vacuum adsorption device to generate negative pressure, and attach the explosion-proof sheet to the edge of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com