Intelligent pipelining technology for manufacturing woven hats by adopting ultrasonic fusing technique

An ultrasonic and fusion technology, applied in hats, applications, hat products, etc., can solve the problems of inability to realize automation and intelligence, low production efficiency of woven hats, etc., and achieve the effect of improving seam efficiency and beautiful bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

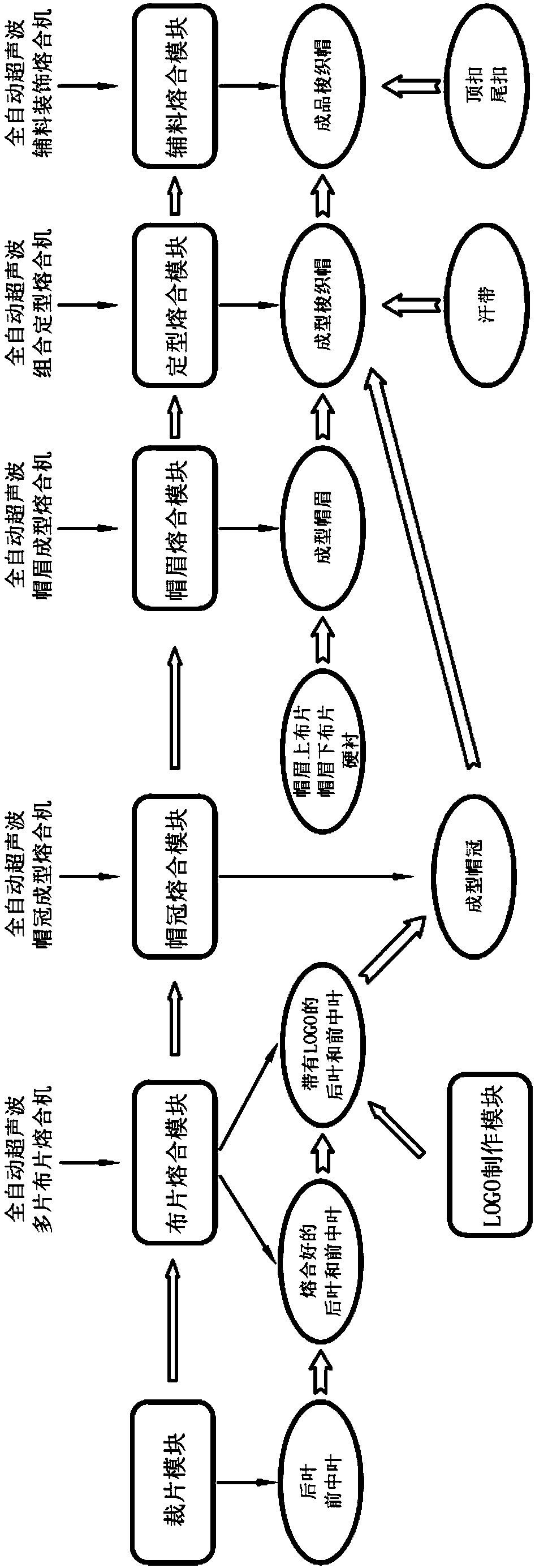

[0021] An intelligent flow process for making woven caps using ultrasonic fusion technology includes a fully automatic assembly line, a woven cap making module, and an intelligent monitoring center. The woven cap making module includes a cutting module, a cloth piece fusion module, and a LOGO making module , crown fusion module, hat eyebrow fusion module, shaped fusion module, and auxiliary material fusion module. The cloth fusion module, crown fusion module, hat eyebrow fusion module, shaped fusion module and auxiliary material fusion module all adopt automatic ultrasonic fusion machines Completed, the automatic assembly line is used to transport the cloth or tooling between each module. The process of each module is monitored an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com