Insulation manufacturing method of full hydrogen-cooled turbine generator stator parallel ring lead

A technology of turbogenerators and connecting loop leads, which is applied in the manufacture of motor generators, laying solid insulation, electrical components, etc., can solve the problem that it is difficult to achieve the service life of parallel loop lead wire insulation and affect the safety of full hydrogen-cooled turbogenerators Operation, affecting the insulation quality of stator parallel ring leads, etc., to achieve the effects of avoiding delamination, ensuring safety, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

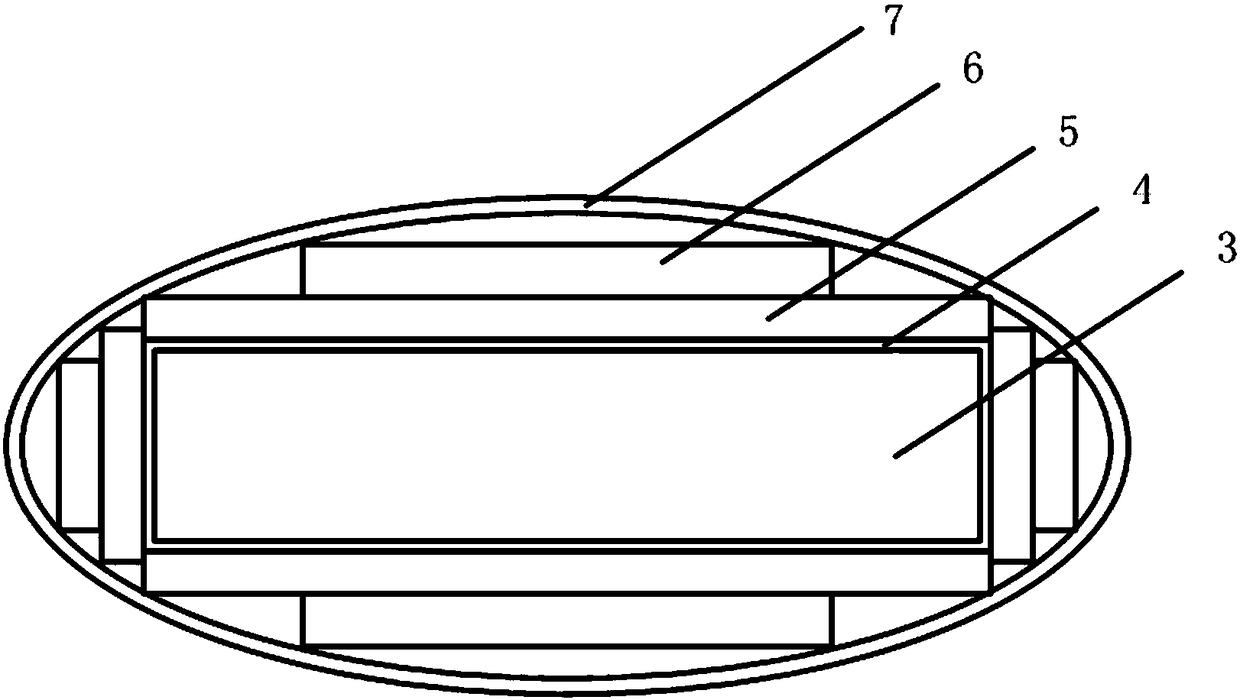

[0017] The present invention is a method for manufacturing the lead wire insulation of the parallel connection ring of the stator of the all-hydrogen-cooled turbogenerator, which includes the following manufacturing steps:

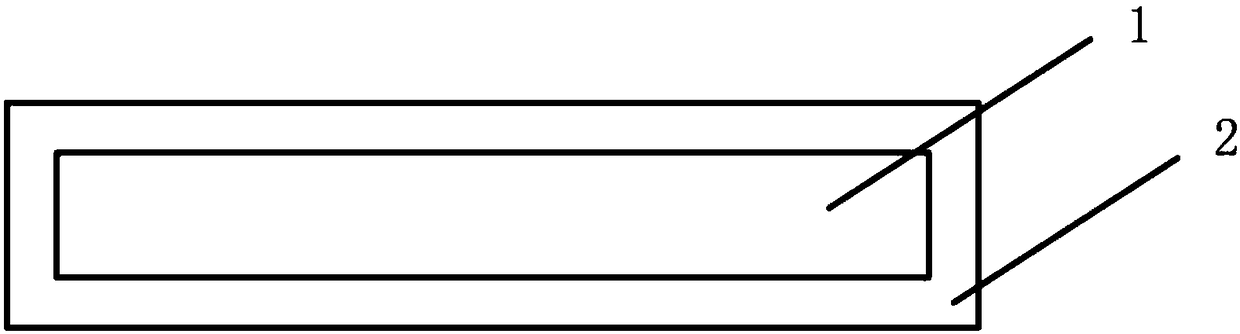

[0018] a. Insulation material selection and wrapping process: Use a universal wrapping machine to enter the factory for wrapping, set the wrapping method of the universal wrapping machine to 1 / 2 overlapping winding, set the wrapping tension to 45N, fix the copper bar on the universal wrapping machine, and place the copper bar on the Brush 1 layer of adhesive on the surface, start the universal wrapping machine and wrap 25 layers of Tongma epoxy glass powder mica tape with a width of 25mm and a thickness of 0.14mm on the copper bar in a 1 / 2 overlapping wrapping method, and wrap Tongma epoxy glass For powder mica tape, brush 1 layer of adhesive on the outer surface after each layer is wrapped, and scrape off the excess adhesive on the insulating surface while...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com