Feature fitting-based visual inspection method for substation instrument and equipment inspection

A visual inspection and substation technology, applied in the direction of instruments, character and pattern recognition, computer components, etc., can solve problems such as vibration or other external factors interference, image quality is not stable enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings.

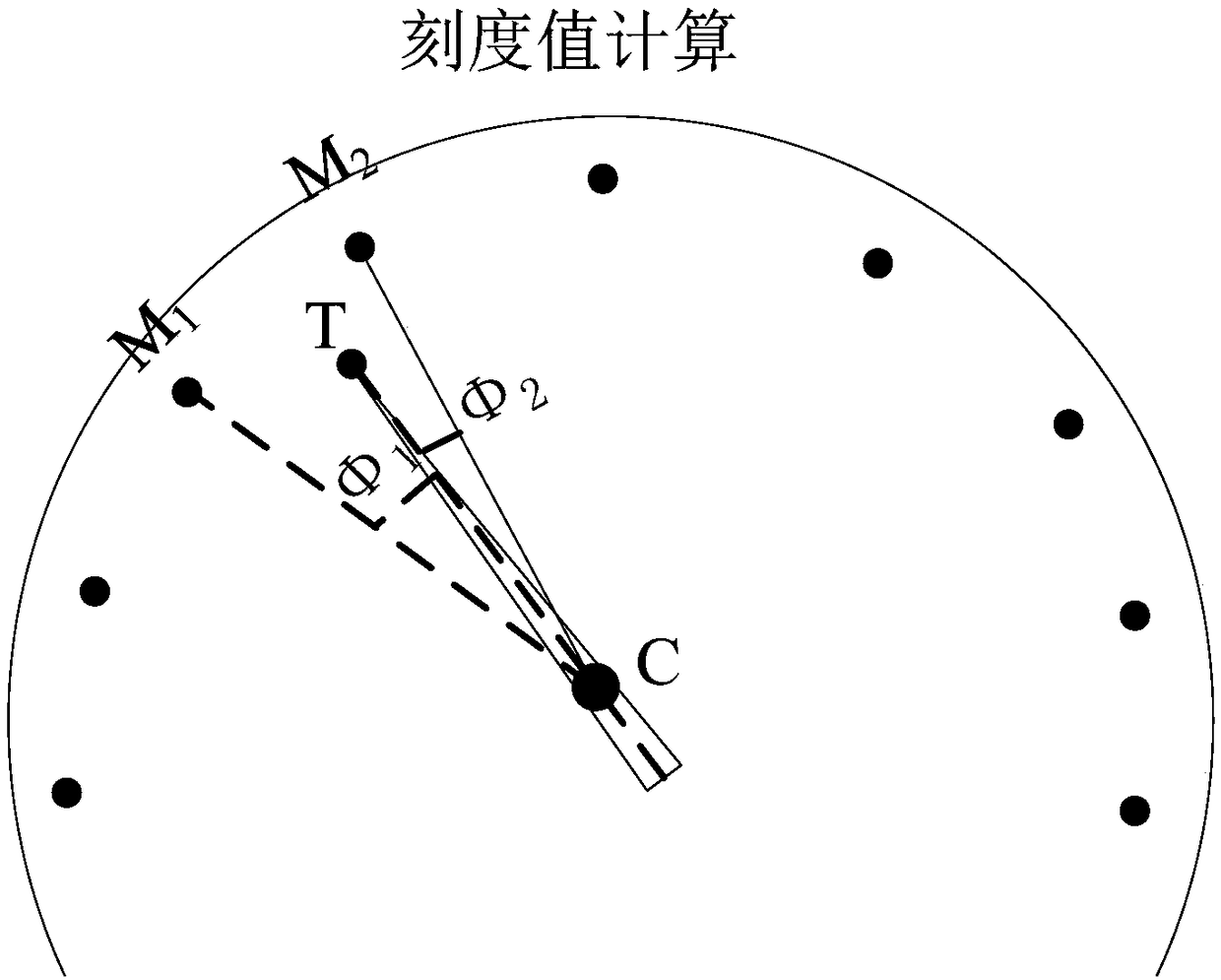

[0071] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a visual inspection method for inspection of substation instrumentation equipment based on feature fitting, specifically includes the following steps, see Figure 4 :

[0072] Step 1. Collect an image of a substation inspection instrument, specifically take a target image with a CCD camera and convert the image into a grayscale image G;

[0073] Step 2. Perform preprocessing on image G to remove noise points and generate image G1.

[0074] Step 3. Use the edge operator to extract the edge information of G1 to generate image G2.

[0075] Step 4. Use the Hough algorithm to analyze the circular target in the image G2, and calculate the meter center C.

[0076] This stage is the meter pointer calculation:

[0077] Step 5. Surrounding the instrument center C, perform projection mapping on the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com