house building tools

A tool and house technology, which is applied in the field of house construction, can solve the problems of increasing the measurement process, the difficulty of accurately controlling the angle of the wall brick layer, and the cumbersome process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

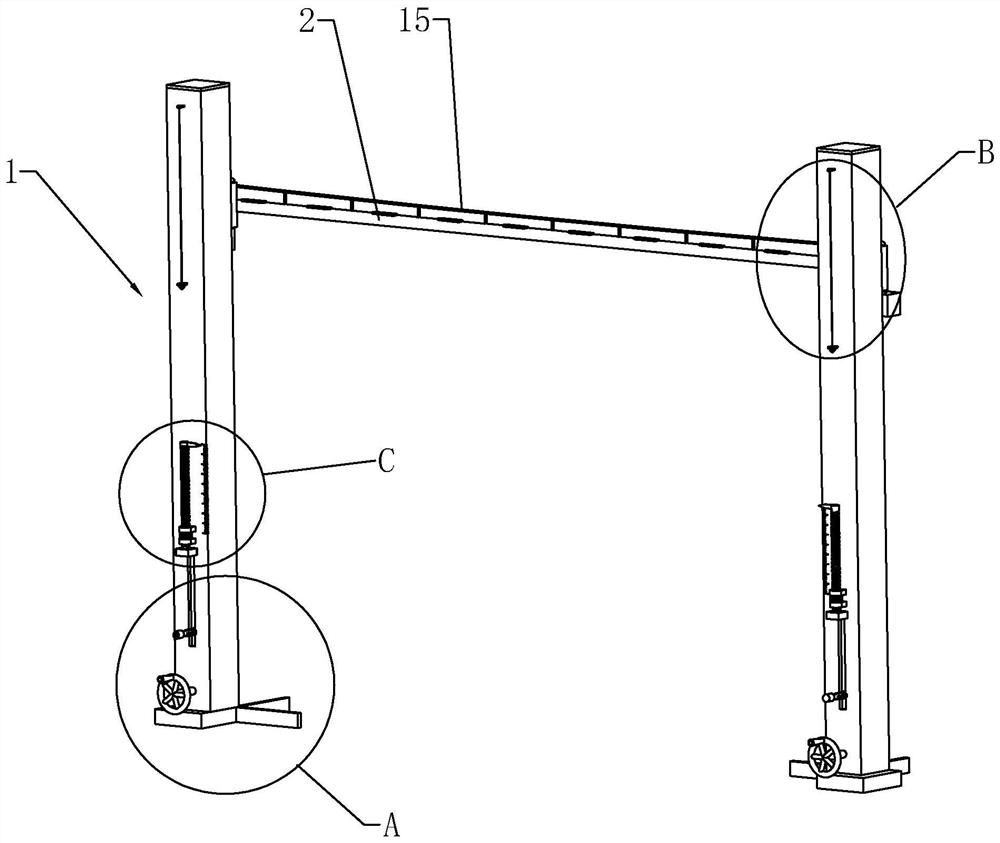

[0049] Embodiment 1: Reference figure 1 , a house building tool, including a corner frame 1, the corner frame 1 is used to fix the corner of the house, and also includes a leveling rod 2, the leveling rod 2 is erected between the two corner frames 1, when the house is built , taking the leveling rod 2 as a reference line, so that good straightness and levelness can be maintained during the brick masonry process.

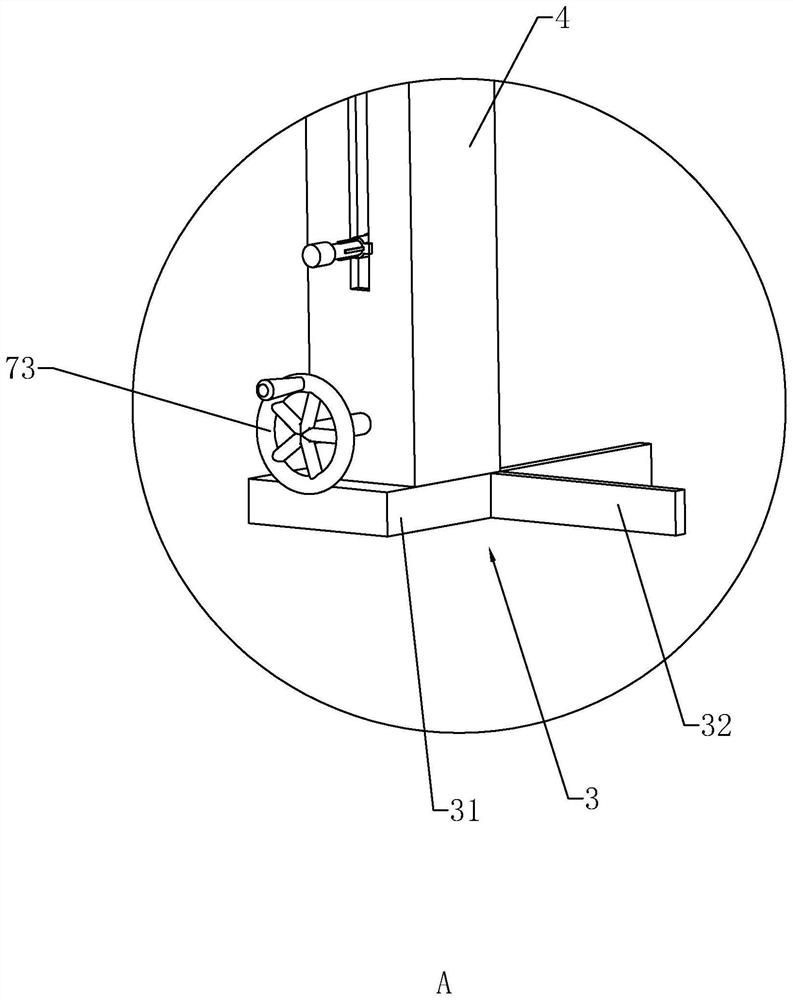

[0050] refer to figure 1 and figure 2 , the corner frame 1 includes a base 3, the base 3 is provided with a riser 4, the base 3 is used to fix the riser 4 on the ground of the corner or on the foundation wall, the base 3 includes a bottom plate 31 and two positioning plates perpendicular to each other 32. On the installation corner frame 1, the positioning of the corner frame 1 in three different directions is realized through the base 3 and two positioning plates 32, which is convenient for fixing the corner frame 1 when installing the corner frame 1. In this em...

Embodiment 2

[0057] Embodiment two: a kind of building masonry method, comprises the following steps:

[0058]Step 1, digging grooves, digging grooves and laying out wires on the ground according to the house design drawings, excavating the foundation grooves required for masonry foundation walls after setting out the wires, leveling and compacting the foundation in the foundation grooves;

[0059] Step 2: Build the foundation wall. On the ground that has been rammed in step 1, lay out bricks for the foundation wall and lay out the foundation wall. After the laying out, build the foundation wall.

[0060] Step 3, build the main wall. Build the main wall on the foundation wall built in step 2. When building the main wall, use the corner frame and leveling rod as a reference for building the main wall;

[0061] Step 4, capping, after the main wall is built, install the roof on the wall.

[0062] The house construction is completed through the steps of digging trenches, building foundation w...

Embodiment 3

[0063] Embodiment 3: Different from Embodiment 1, in this embodiment, if Figure 10 and Figure 11 , The bottom plate 31 is arranged on the inner side of the right angle formed by the two positioning plates 32, so when the bottom plate 31 and the positioning plate 32 are installed on the inner side of the corner, the positioning plate 32 can fit the wall well.

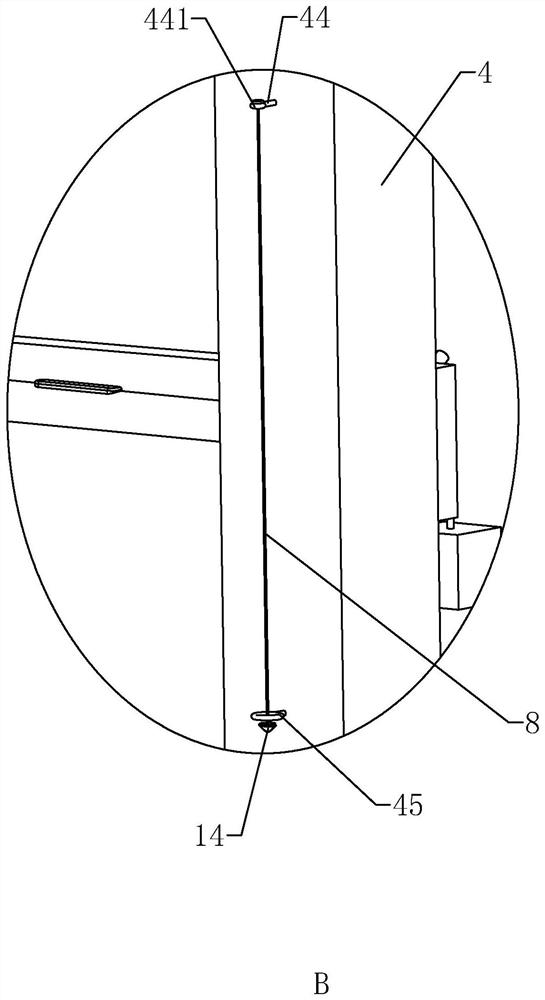

[0064] Steps for using the corner frame 1: After building the foundation wall of the house, install the corner frame 1 at the corner of the wall. When installing the corner frame 1, control the corner frame 1 to be in a vertical state by comparing and observing the hanging rope 8 and the comparison ring 45. Then the leveling bar 2 is erected on the first oblique rod 52 on the two angle frames 1, and the tension rope 15 is erected on the second oblique rod 53 on the two angle frames 1 and the tension rope 15 is set up by the counterweight 16 Stretch straight, connect the stay cord 17 between the tensioning rope 15 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com