Textile cloth cleaning device

A cleaning device and a technology for textile fabrics, which are applied in the processing of textile materials, spray/jet textile material processing, textiles and papermaking, etc., can solve the problems of cumbersome steps, time-consuming, fabric stretching, etc., and achieve good drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

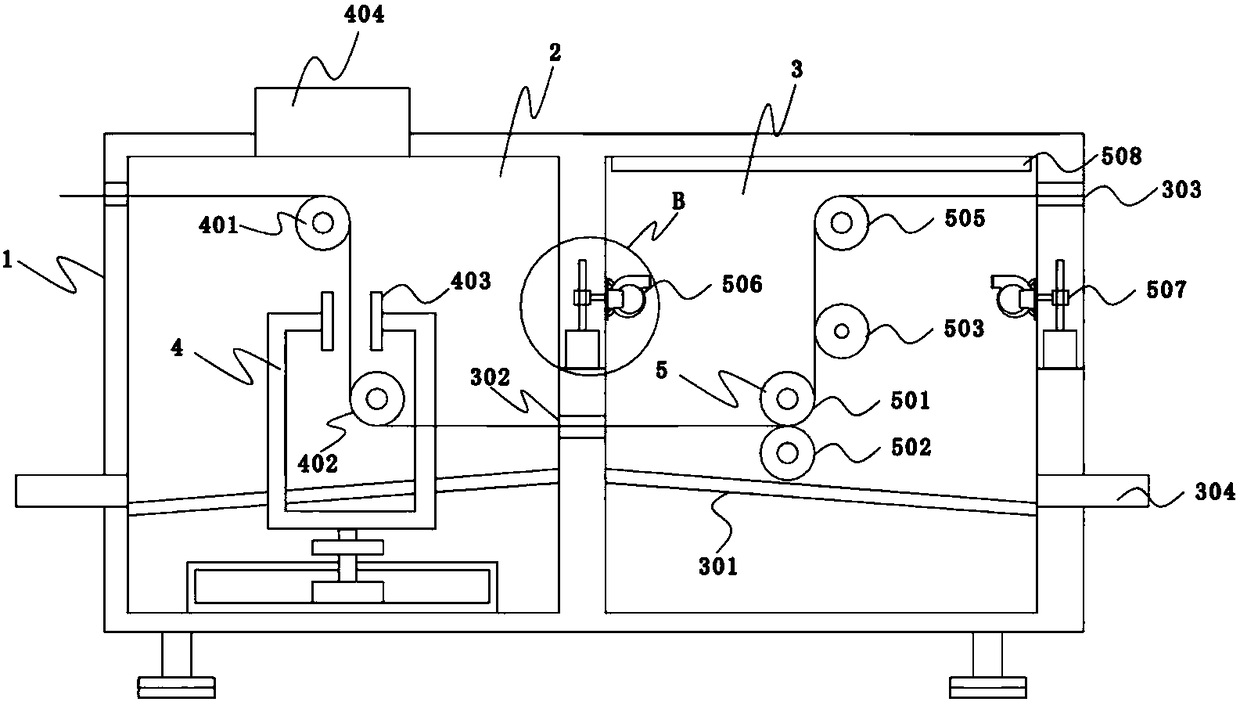

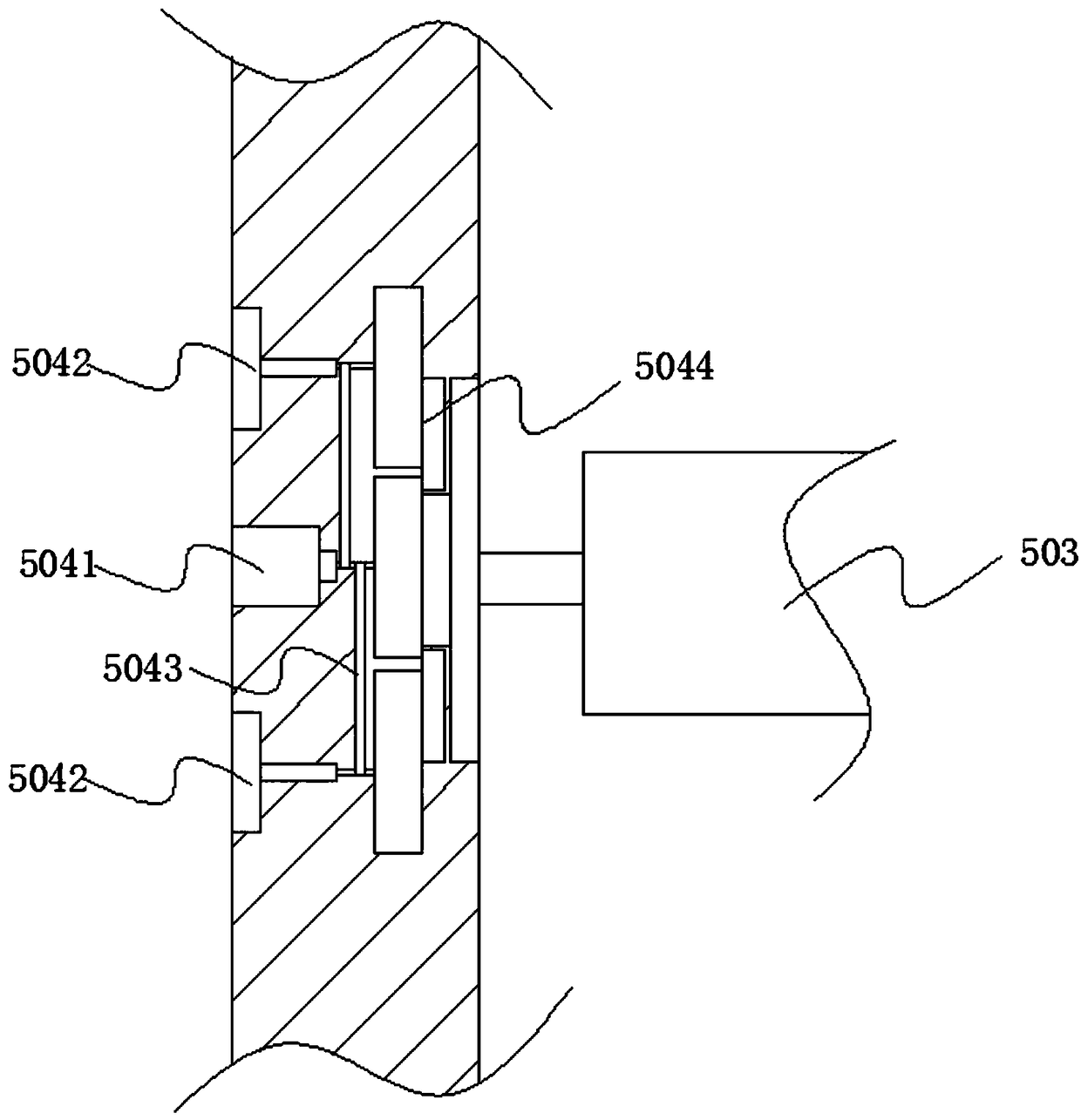

[0020] Such as Figure 1-5 As shown, a textile cloth cleaning device includes a box body 1, a first accommodating chamber 2, a second accommodating chamber 3, a cleaning mechanism 4 and a drying mechanism 5; the first accommodating chamber 2 and the second accommodating chamber 3 are provided with In the box body 1, the cleaning mechanism 4 is arranged in the first chamber 2, and the drying mechanism 5 is arranged in the second chamber 3; the drying mechanism 5 includes a first extrusion roller 501, a second extrusion roller Roller 502, drying part 503, first lifting device 504, guide roller 505, air-drying part 506, second lifting device 507 and heating element 508; describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com