Differential double-impeller underwater fine-bubble aeration device and method thereof

A technology of aeration device and double impeller, applied in the field of water pollution control, can solve the problems of large bubbles, poor dissolved oxygen efficiency, short gas-liquid contact time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

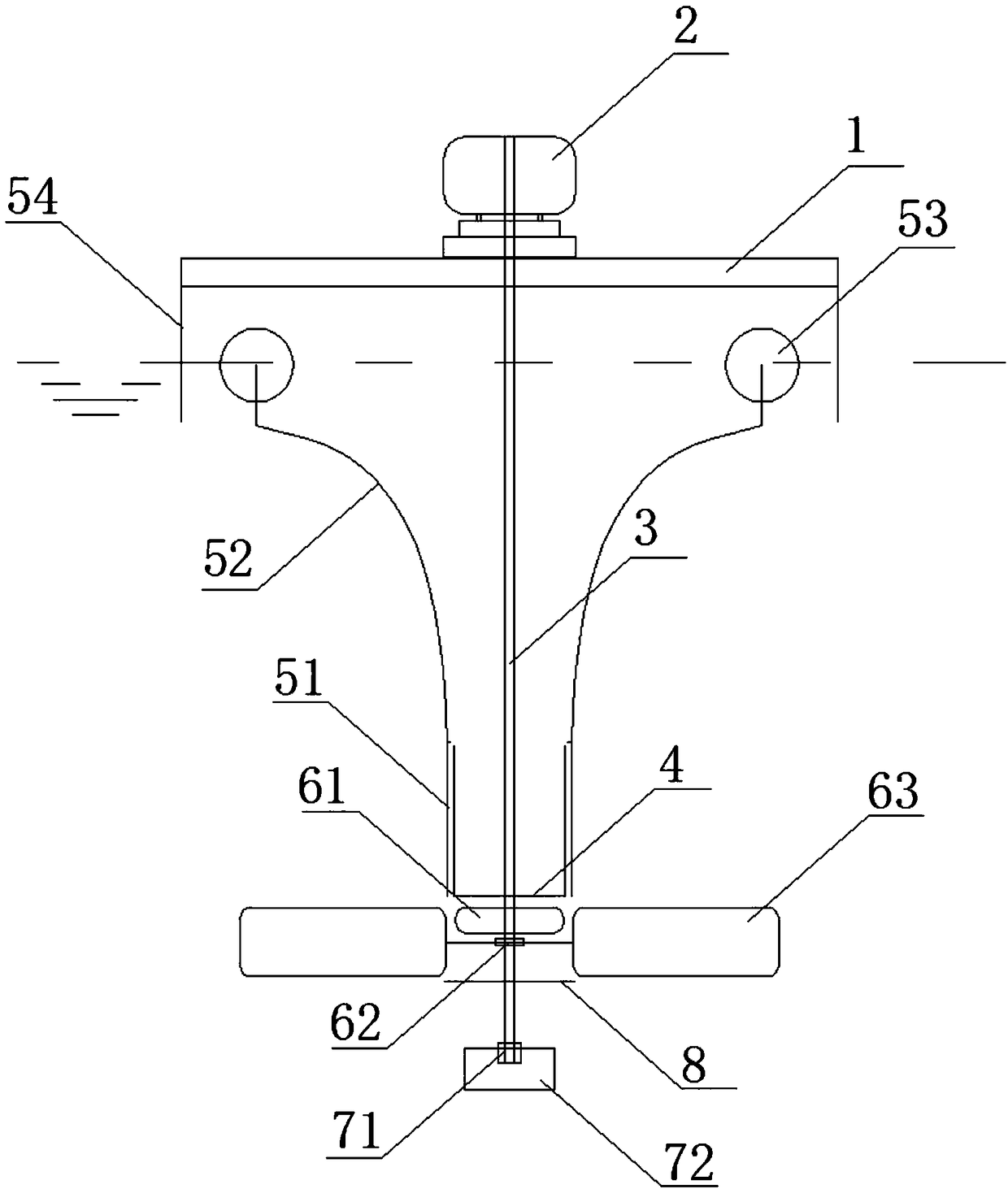

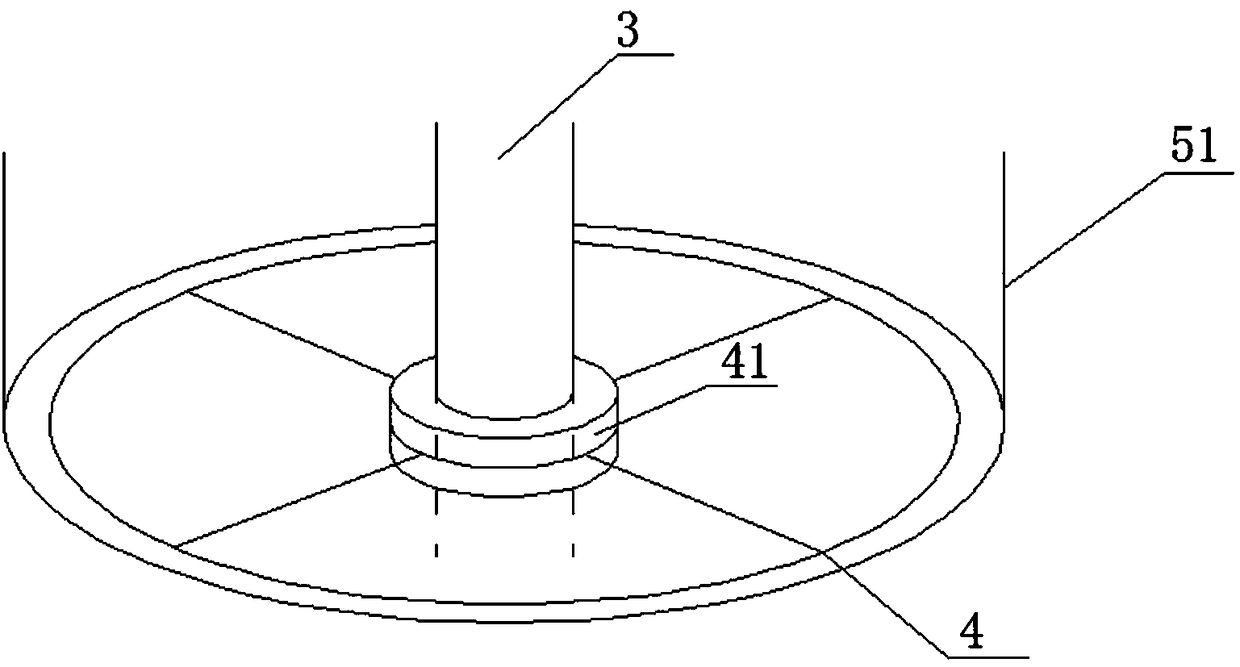

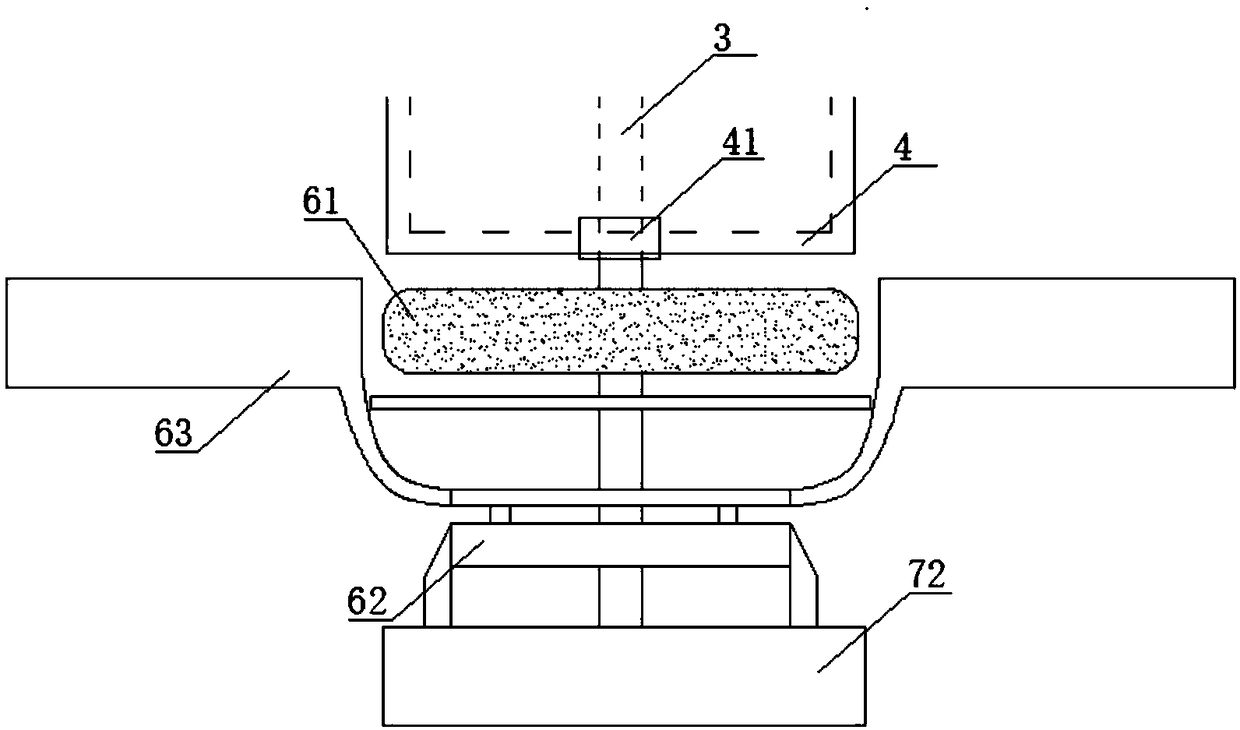

[0040] Such as Figure 1~3 , A differential dual-impeller underwater microbubble aeration device, installed on a horizontal platform 1, including a motor 2 vertically installed on the platform 1, with a speed greater than 3000 rpm, and also including a transmission shaft connected to the motor 2 Shaft 3, a base 72 installed at the bottom of the water, the base 72 vertically corresponds to the position of the motor 2, a base 72 bearing is provided in the center of the base 72, and the transmission shaft 3 is connected to the base 72 through the base 72 bearing;

[0041] The device also includes a high-speed impeller 61 and a reducer 62 installed at the bottom of the drive shaft 3. The low-speed impeller 63 and the high-speed impeller 61 are at the same height; the surface of the high-speed impeller 61 is provided with a plurality of tiny protrusions; The low-speed impeller 63 at the output end of the reducer 62 also includes a baffle 8 arranged below the high-speed impeller 61 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com