Suction disc device and bottle preform conveying mechanism

A technology of suction cups and suction cup seats, which is applied in the direction of conveyors, conveyor objects, suction cups, etc., can solve the problems that the preform is difficult to ensure the adsorption movement, affects the production progress and efficiency, and the preform falls, etc., and achieves simple structure and improved Speed and success rate, the effect of firm adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

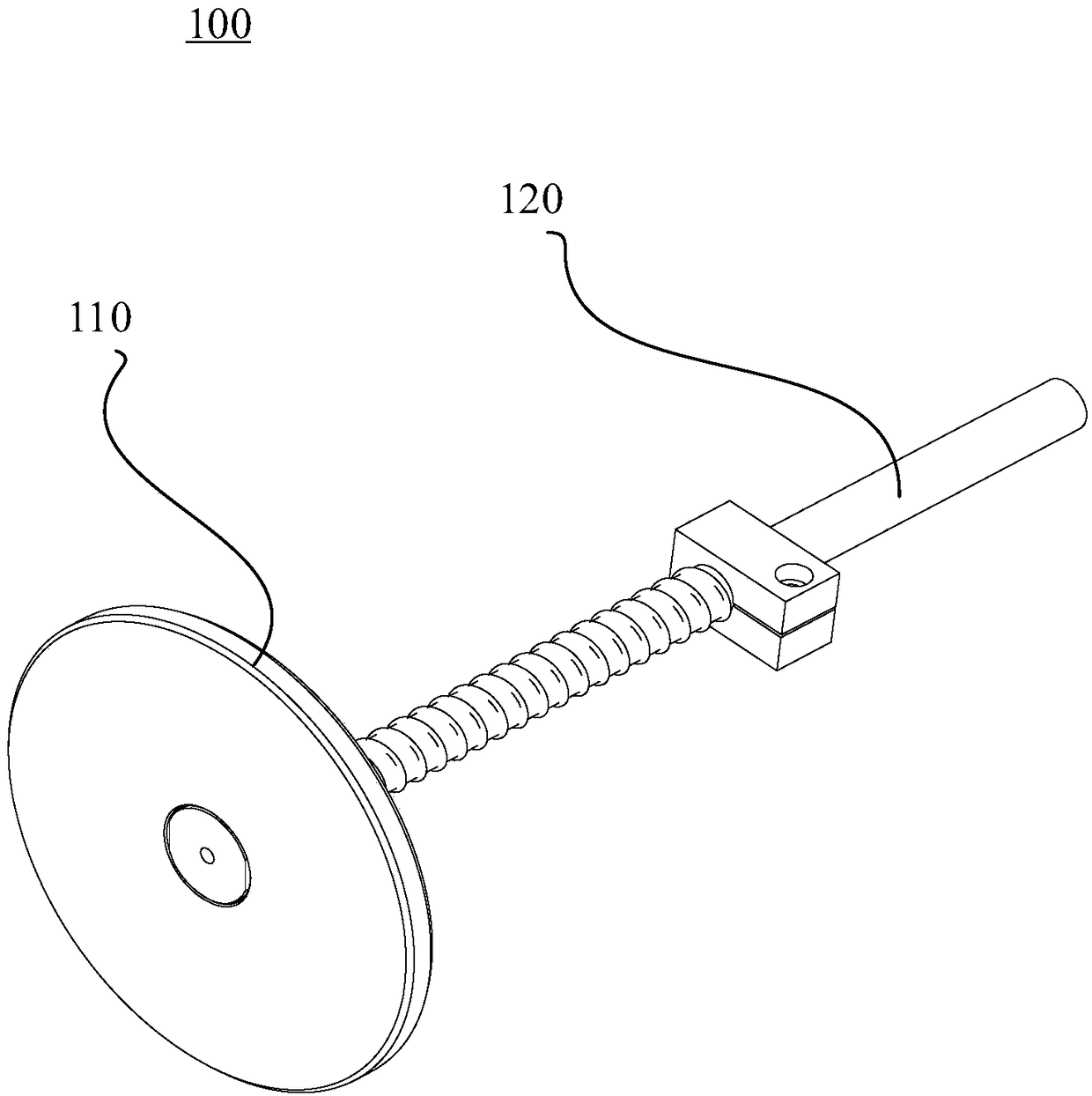

[0030] Please refer to figure 1 , the present embodiment provides a sucker device 100, which includes a sucker seat 110 and a connecting pipe 120, the suction surface of the sucker seat 110 is a plane, a through hole is arranged in the center of the sucker seat 110, the connecting pipe 120 is a hollow pipe, and the connecting pipe 120 One end communicates with the through hole.

[0031] It should be noted that, first, if figure 1 As shown, the center of the suction cup seat 110 is provided with a through hole, the connecting pipe 120 is a hollow pipe, one end of the connecting pipe 120 communicates with the through hole, the other end of the connecting pipe 120 is connected to an external suction mechanism, and the suction surface of the suction cup seat 110 contacts and fits The bottle mouth is closed after the surface of the bottle mouth, so that a closed space is formed in the bottle, and the external suction mechanism exhausts the air in the closed bottle through the conn...

no. 2 example

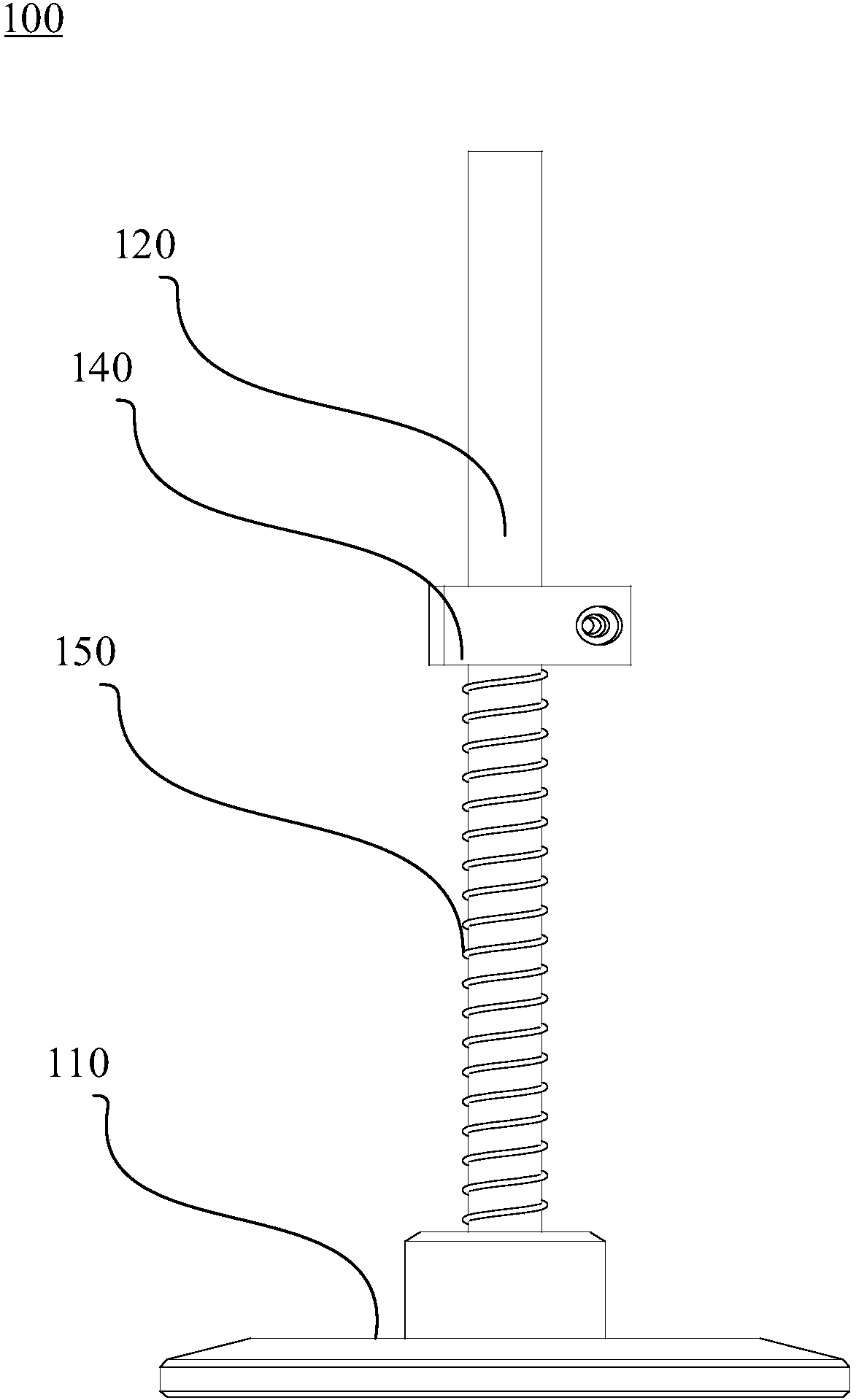

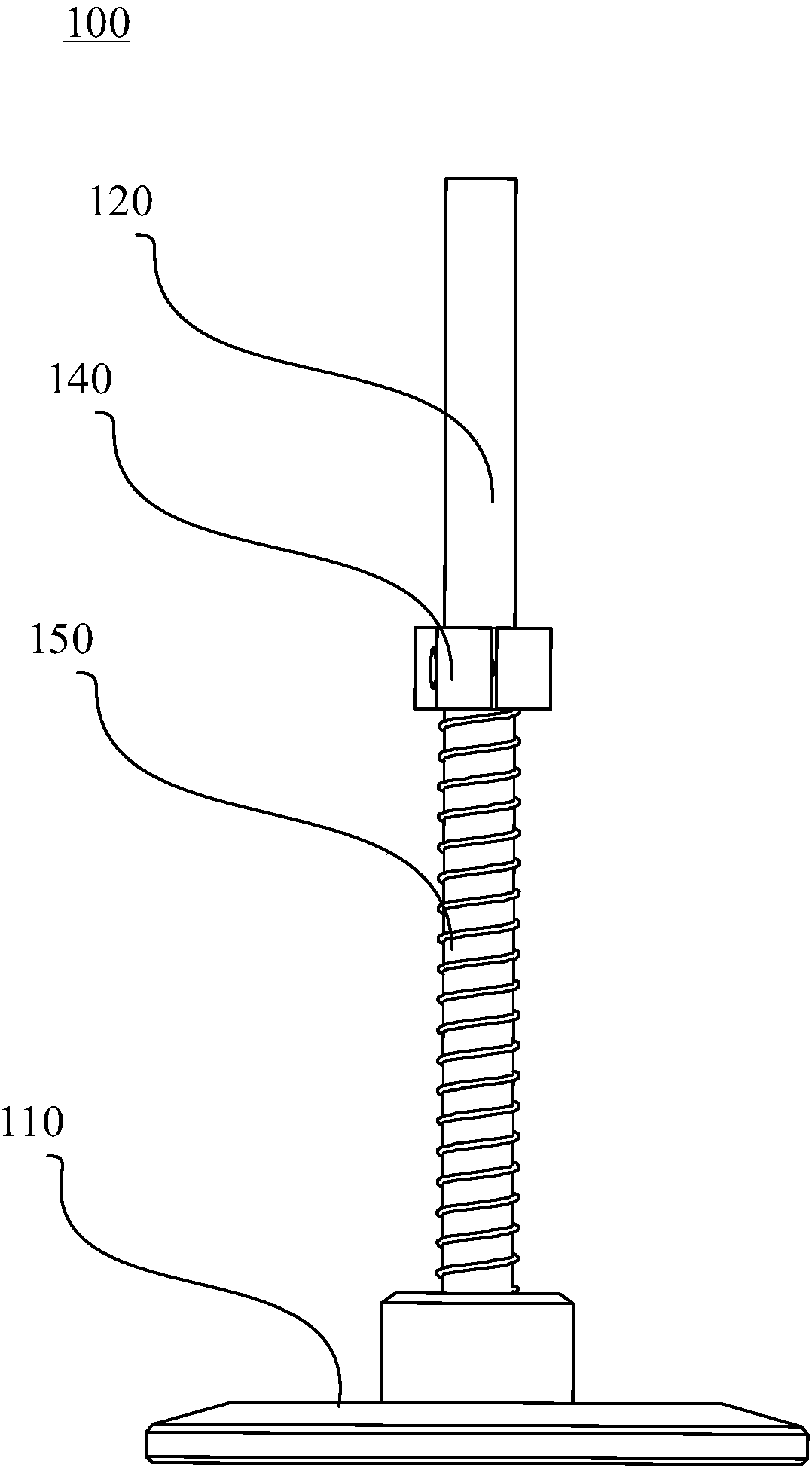

[0052] This embodiment provides a preform conveying mechanism including a suction mechanism, a lifting mechanism and any one of the above-mentioned suction cup devices 100, the suction cup device 100 is connected to the suction mechanism through a connecting pipe 120, and the suction cup device 100 is connected through a fixed block 140 and a lifting mechanism connect.

[0053] This embodiment provides a preform conveying mechanism. When the preform is adsorbed, the above-mentioned lifting mechanism moves the suction cup device 100 to the position above the preform through the fixed block 140 and then slowly descends, so that the suction surface of the suction cup seat 110 contacts and fits the bottle mouth. Close the mouth of the bottle after the surface, so that a closed space is formed in the bottle, and the other end of the connecting pipe 120 is connected to the above-mentioned suction mechanism. The air pressure inside the bottle is lower than the outside air pressure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com