Braking recycling strategy for new energy vehicle

A new energy vehicle, brake recovery technology, applied in the direction of electric vehicles, electric braking systems, vehicle components, etc., can solve the problems of waste of capacity, low efficiency of motor recovery, etc., and achieve the effect of improving energy recovery by braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The concrete implementation method of the present invention is as follows:

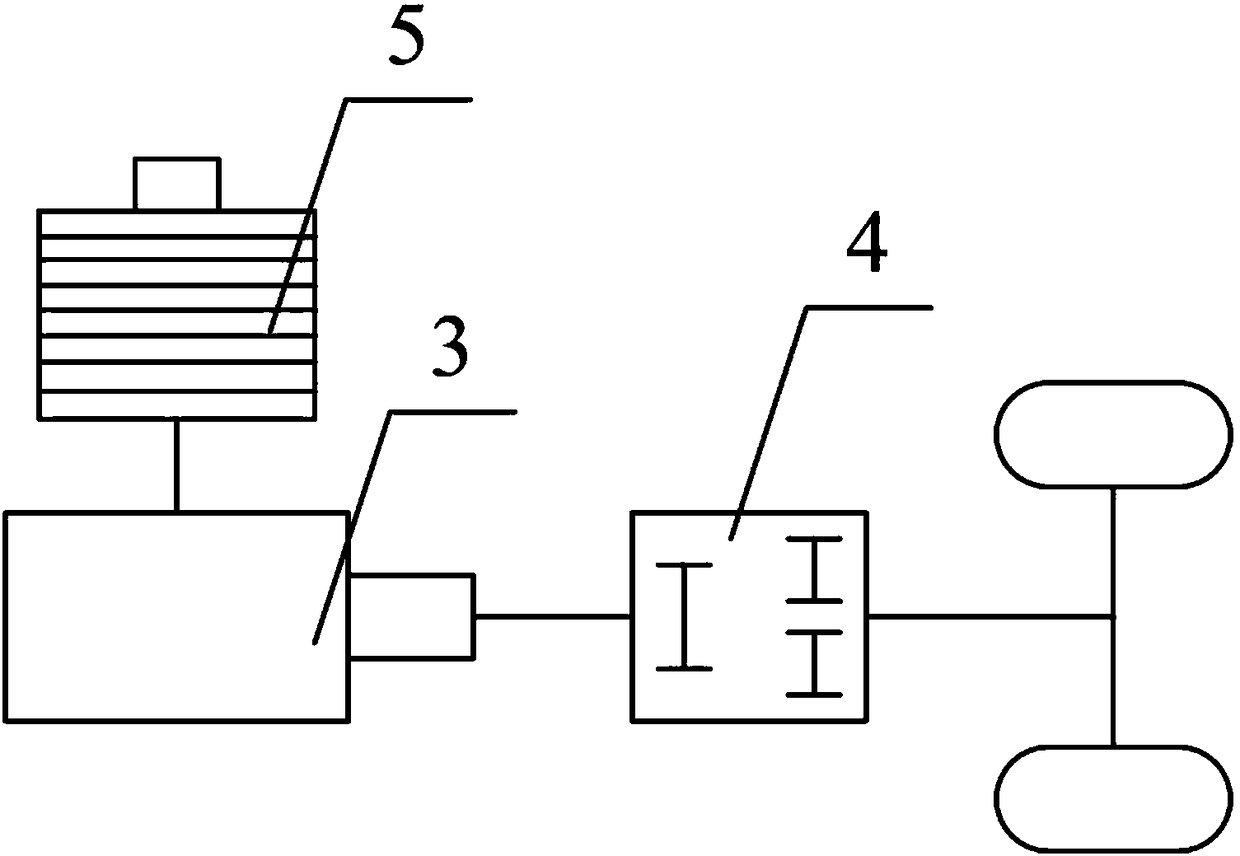

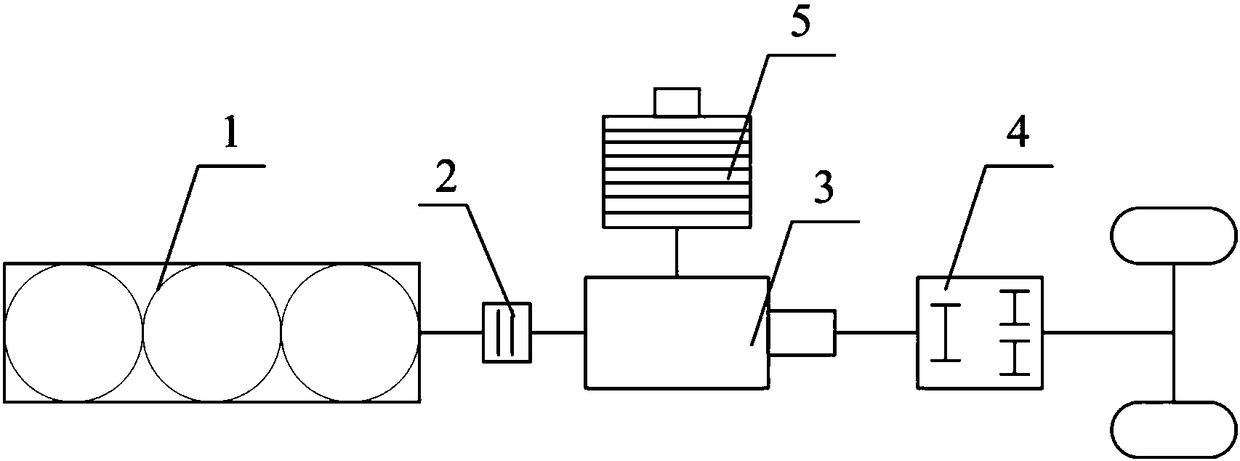

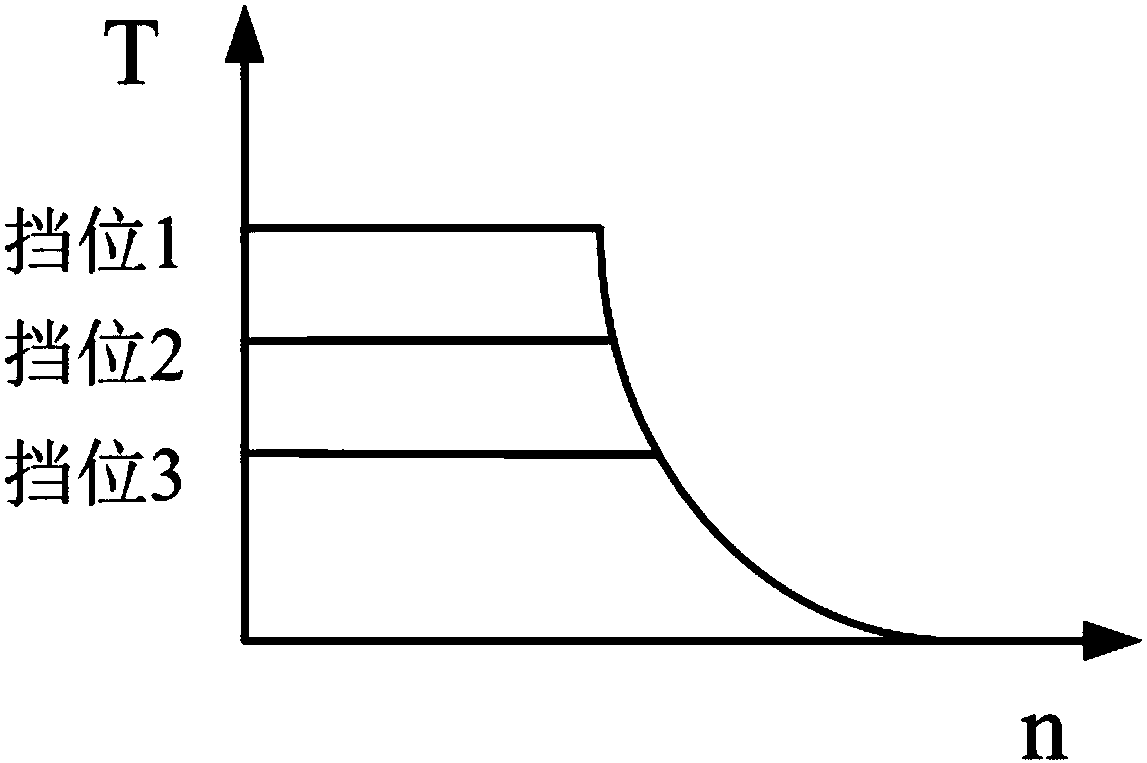

[0017] New energy vehicles include pure electric vehicles, hybrid vehicles, etc. Both pure electric vehicles and hybrid vehicles include electric motors. In order to meet the needs of vehicle power and various complex working conditions, existing pure electric vehicles and hybrid vehicles, It is often equipped with a gearbox to improve power and economy. For pure electric vehicles and hybrid vehicles, the electric motor is usually used to recharge when braking. However, most new energy vehicles use the gearbox when braking. The gear position remains unchanged, and the power generation torque of the electric motor is not the maximum, which leads to the incomplete recovery of kinetic energy and the waste of part of the kinetic energy. Therefore, in order to further improve the efficiency of the kinetic energy recovered by braking, the present invention proposes a new energy vehicle system The mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com