A green food packaging printing device

A technology for packaging printing and green food, applied in printing devices, printing, printing machines, etc., can solve the problems of low printing efficiency, low intelligence, difficult operation, etc., to facilitate accurate printing, improve drying efficiency, and easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

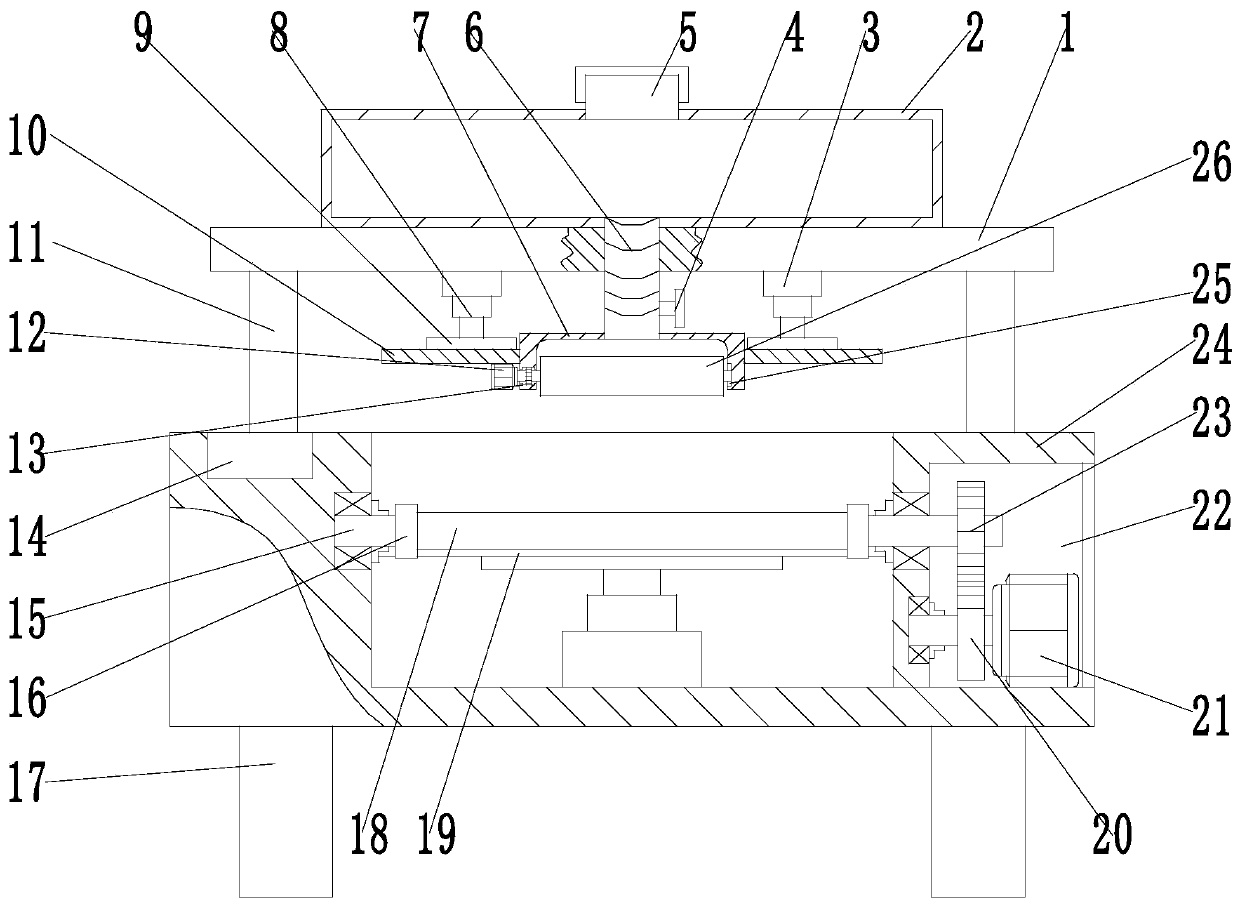

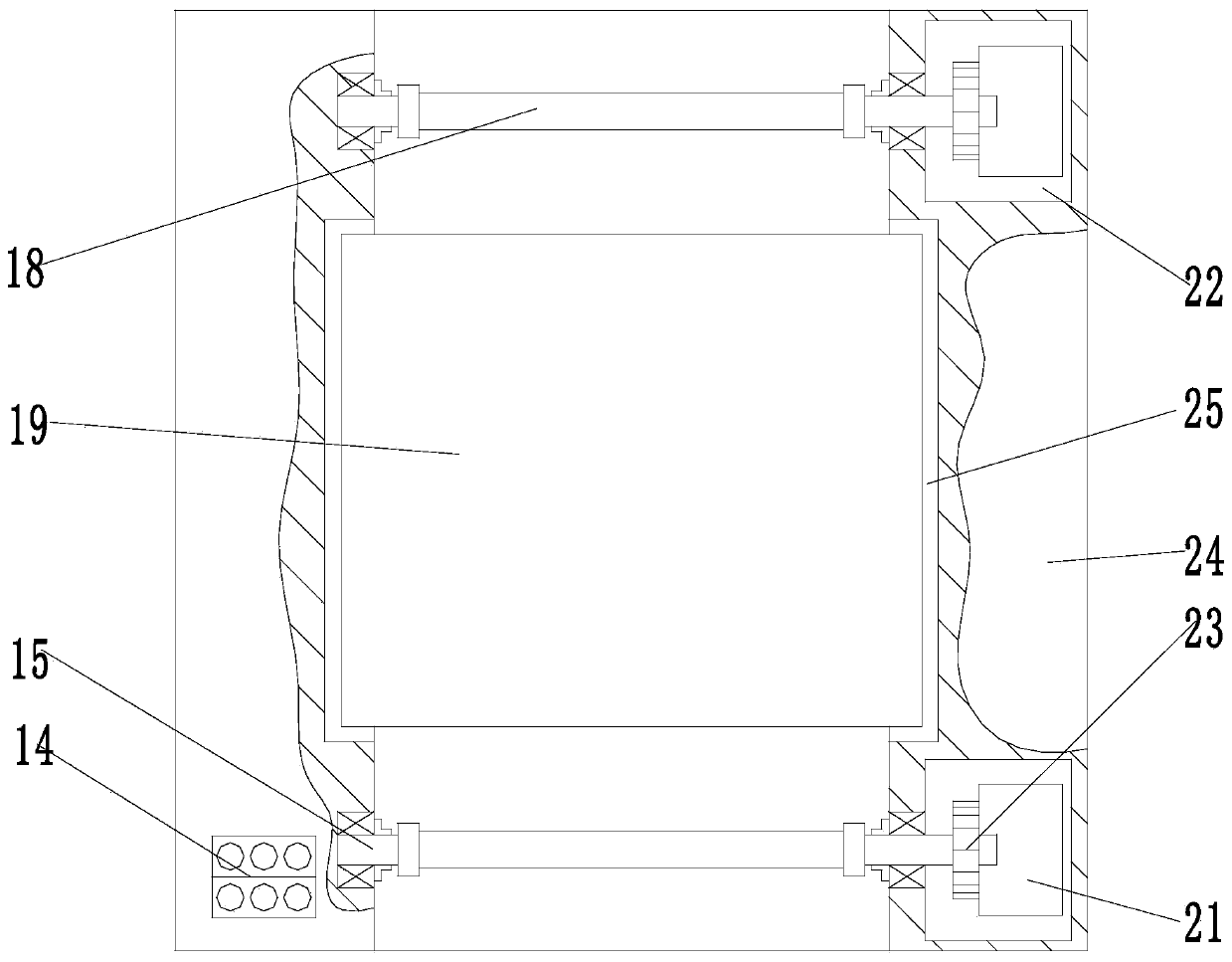

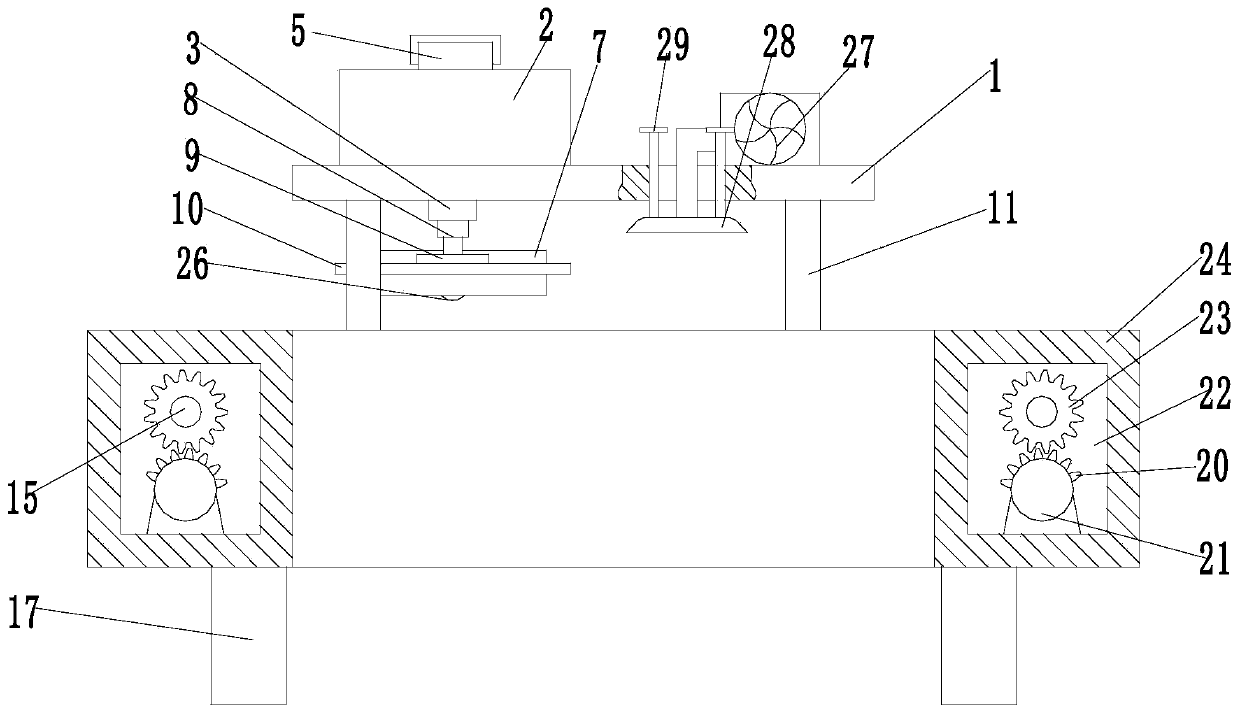

[0021] see Figure 1-4 , a green food packaging and printing device, including a horizontal plate 1, a material storage box 2 and a base 24; the lower surface of the horizontal plate 1 is fixed to the upper end of the column 11 by bolts around the lower surface, and the front end of the upper surface is fixed with a material storage box by bolts 2. The upper end of the column 11 is fixed around the lower surface of the horizontal plate 1 by bolts, and the other end is fixed on the left and right sides of the upper surface of the base 24 by bolts, so as to support the horizontal plate 1; Port 5, the middle part of the lower surface is fixed with a bellows 6 by bolts, and a hot air blower 27 is arranged on the rear side; the upper end of the feed port 5 is threaded with a dust cover, and the lower end is fixed on the upper surface of the material sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com