A hydraulic guide head for band sawing machine and its application method

A band sawing machine and guide head technology, applied in sawing machine devices, metal sawing equipment, metal processing equipment and other directions, can solve the problems of increasing the installation time of the band sawing machine, reducing the work efficiency, reducing the volume of processed materials, etc. Cut range, improve ease of operation, improve the effect of clamping operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

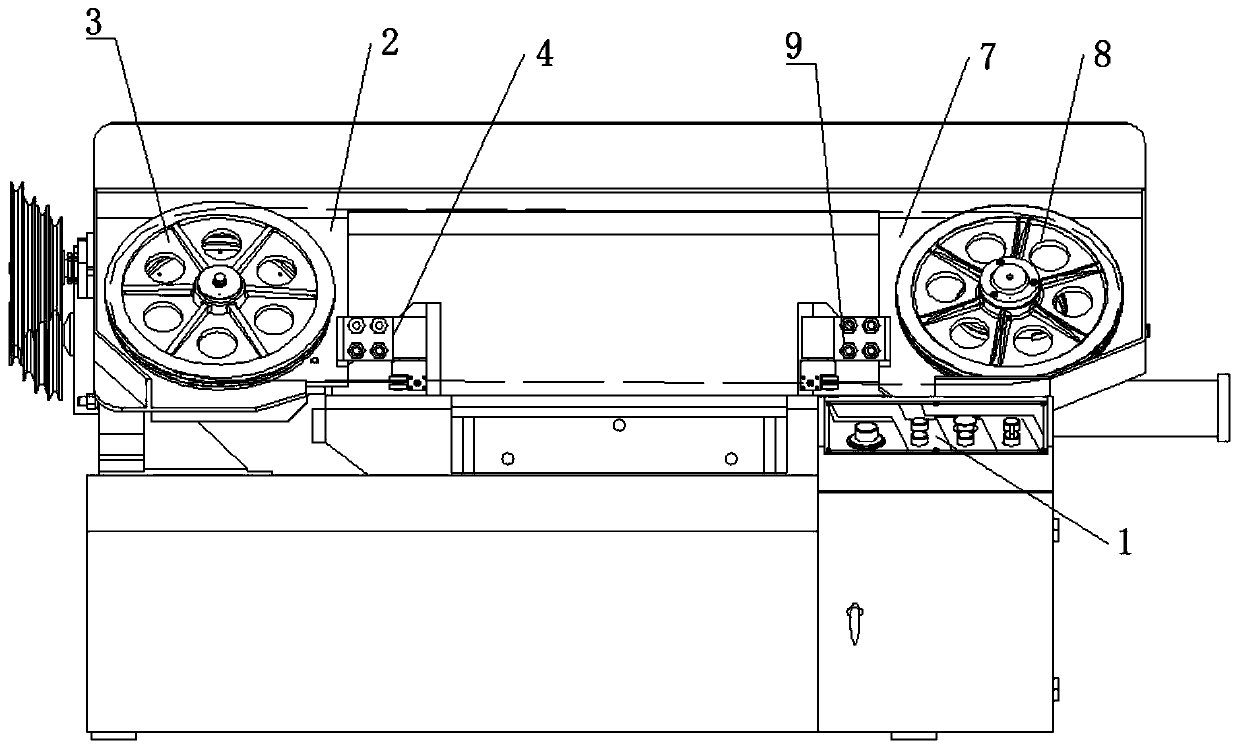

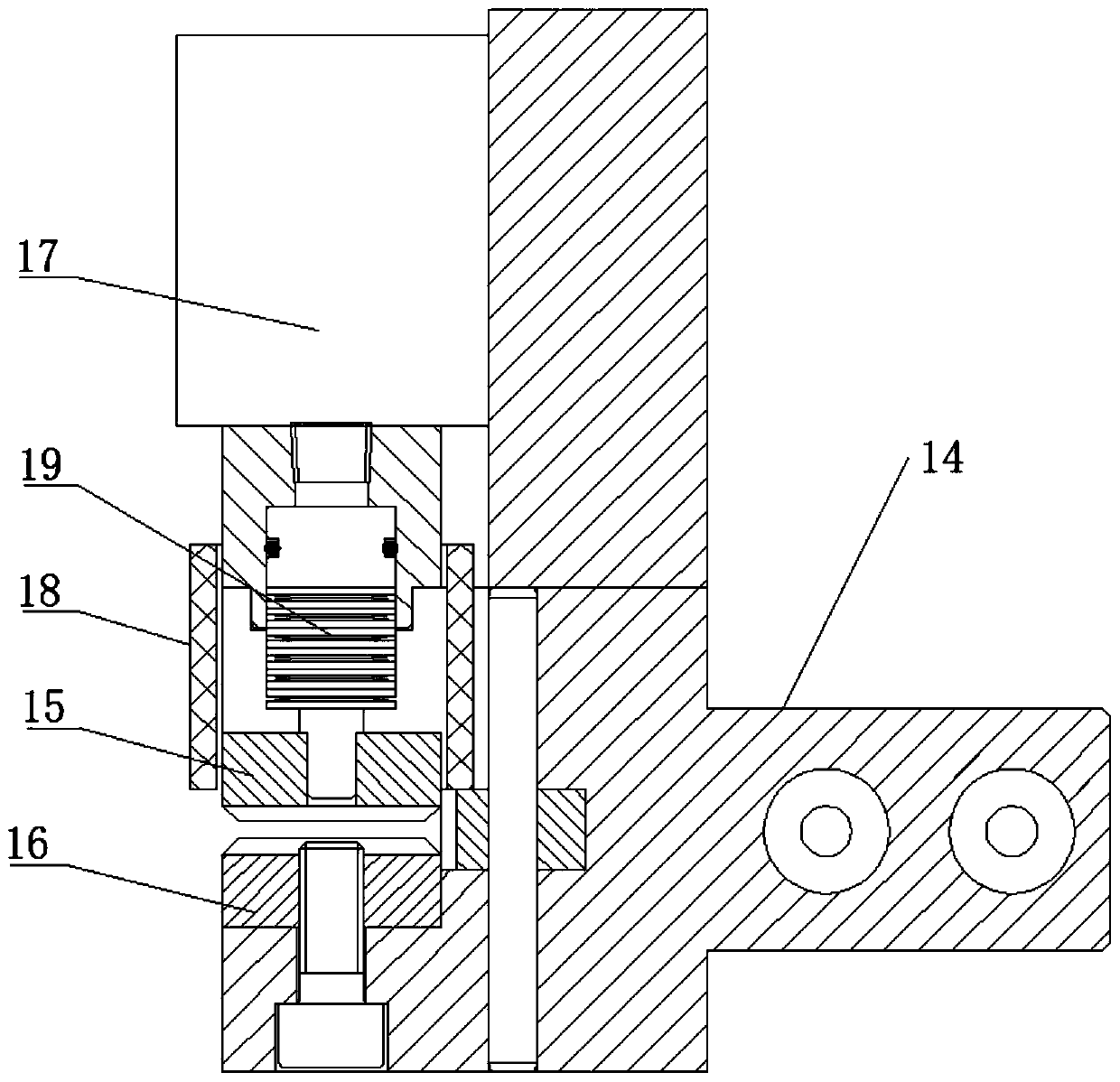

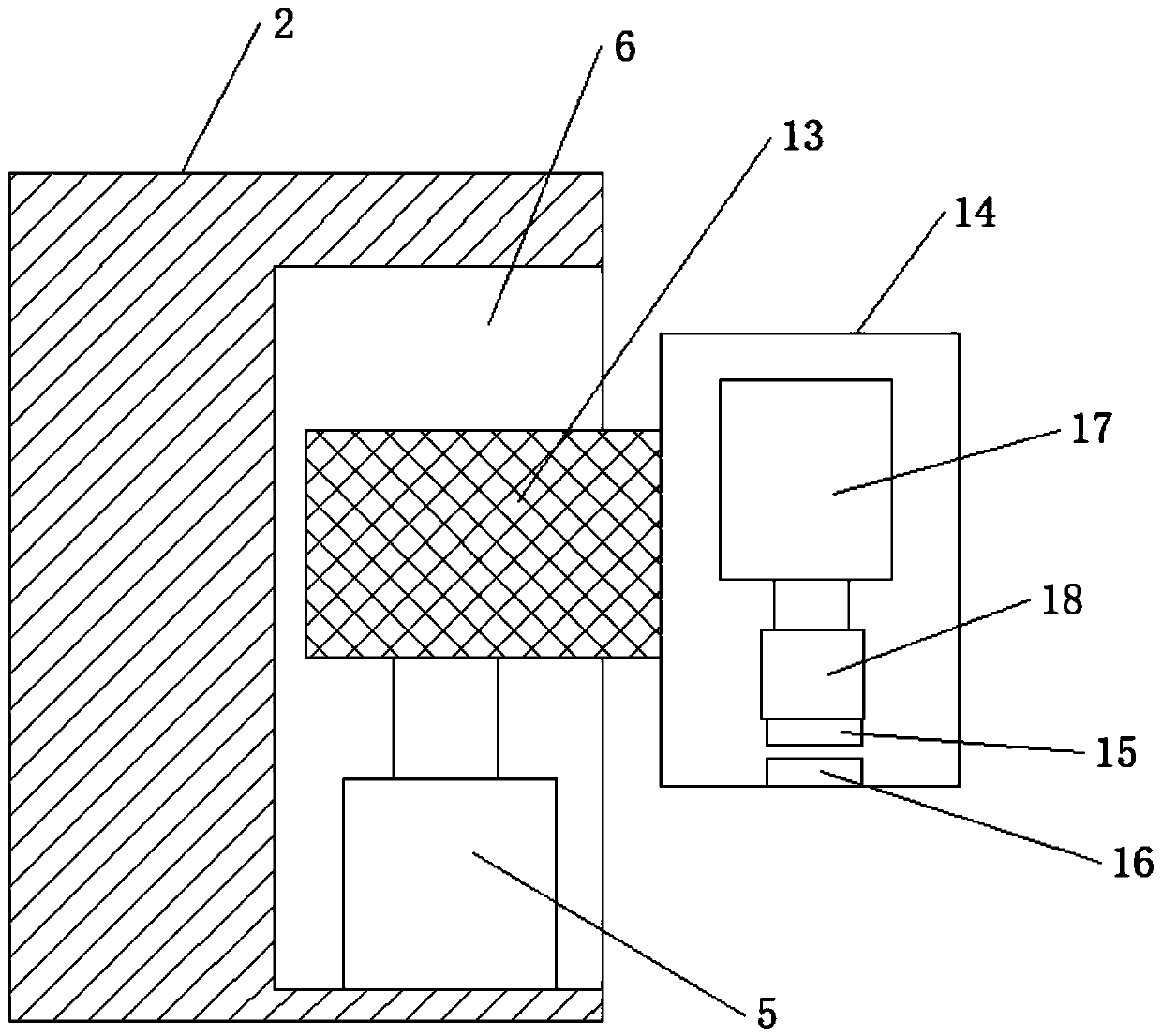

[0029] refer to Figures 1 to 4 As shown, a hydraulic guide head used on a band sawing machine in this embodiment includes a controller 1 and a left guide mechanism and a right guide mechanism that are symmetrically arranged on the bed body of the band saw machine, and the left guide mechanism includes a left Machine base 2, driving pulley 3, left guide 4 and left hydraulic cylinder 5, said left machine base 2 is fixedly installed on the bed body of band sawing machine, said driving belt pulley 3 is rotatably installed on left machine base 2, The motor on the band sawing machine is set in linkage with the driving pulley 3, the right side of the left base 2 is vertically provided with a first sliding groove 6, and the left guide 4 is slidably installed in the first sliding groove 6 Inside, the left hydraulic cylinder 5 is arranged in the first sliding groove 6, and the cylinder body of the left hydraulic cylinder 5 is located at the bottom of the first sliding groove 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com