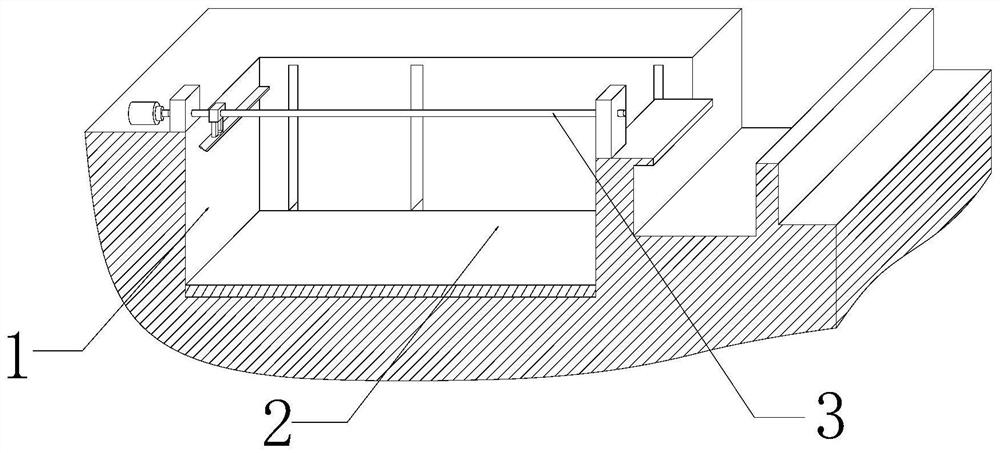

A settling tank for coal processing head

A settling tank and machine head technology, which is applied in the direction of settling tanks, etc., can solve the problems of inconvenient cleaning operation, inconvenient sediment output, time-consuming and labor-intensive problems, and achieve the effects of labor saving, easy removal of sediment, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

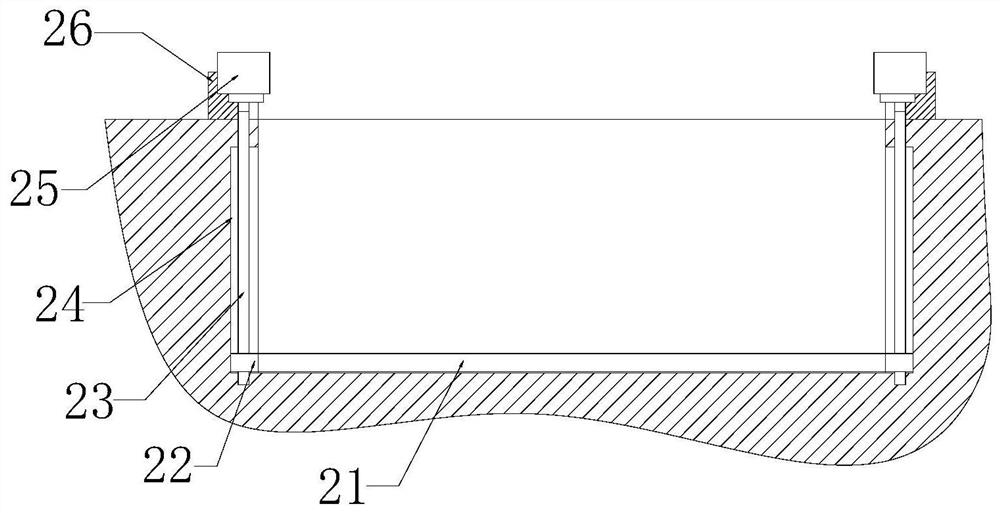

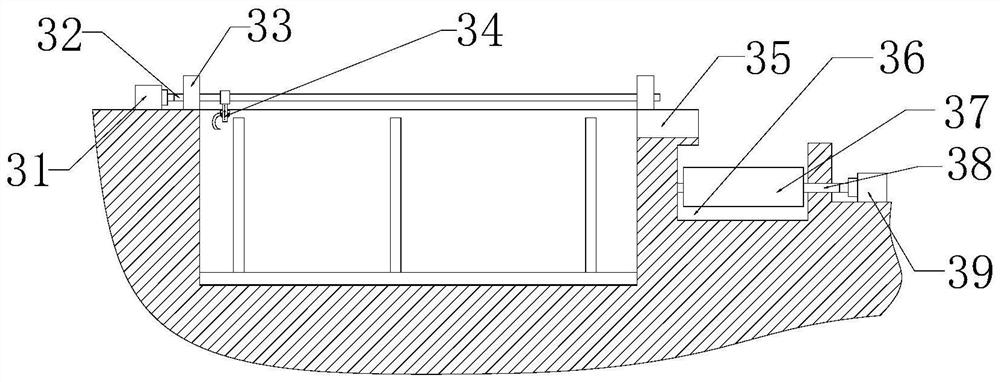

[0025] Specific implementation: when the staff uses the device, the motor one 25 is operated, the motor one 25 works to drive the screw rod one 23 to rotate, and the ball nut pair one converts the rotary motion of the screw rod one 23 into linear motion, so that the ball nut seat one 22 drives the carrier plate 21 to move upward, and the movement of the carrier plate 21 drives the sediment to move. When the sediment moves to the position of the discharge port 35, the staff can stop the motor 25. This design is convenient for the movement of the sediment

[0026] Then the staff makes the motor 2 31 run, the motor 2 31 works to drive the screw rod 2 32 to rotate, and the ball nut seat 2 341 converts the rotary motion of the screw rod 2 32 into linear motion, so that the ball nut seat 2 341 drives the scraper 347 to move, and the scraper 347 moves to scrape off the sediment, and pushes the sediment to move to the right at the same time. When the sediment moves to the position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com