Resin composition for FRP, FRP sheet and molded body

A technology of resin composition and reinforcing sheet is applied in the fields of resin composition, FRP sheet and molded products for FRP, which can solve the problems of reducing the strength of molded products and achieve the effect of inhibiting whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0108] The above-described embodiments do not limit the constitutional features of the present invention. Therefore, based on the description in this specification and common technical knowledge, constituent elements of each part of the above-mentioned embodiments may be omitted, substituted or added, and such omission, substitution and addition shall be construed as falling within the scope of the present invention.

[0109] In addition to the above-mentioned components, modifiers for adjusting physical properties of the polymerized resin and / or for adjusting aesthetic appearance may be contained as additives in the resin composition for FRP as appropriate. Examples of the modifying agent include other various types of monomers, crosslinking agents, fillers, colorants, and the like. As an additive for dispersing the above particles, a monomer combined with, for example, the methyl methacrylate polymer may be used.

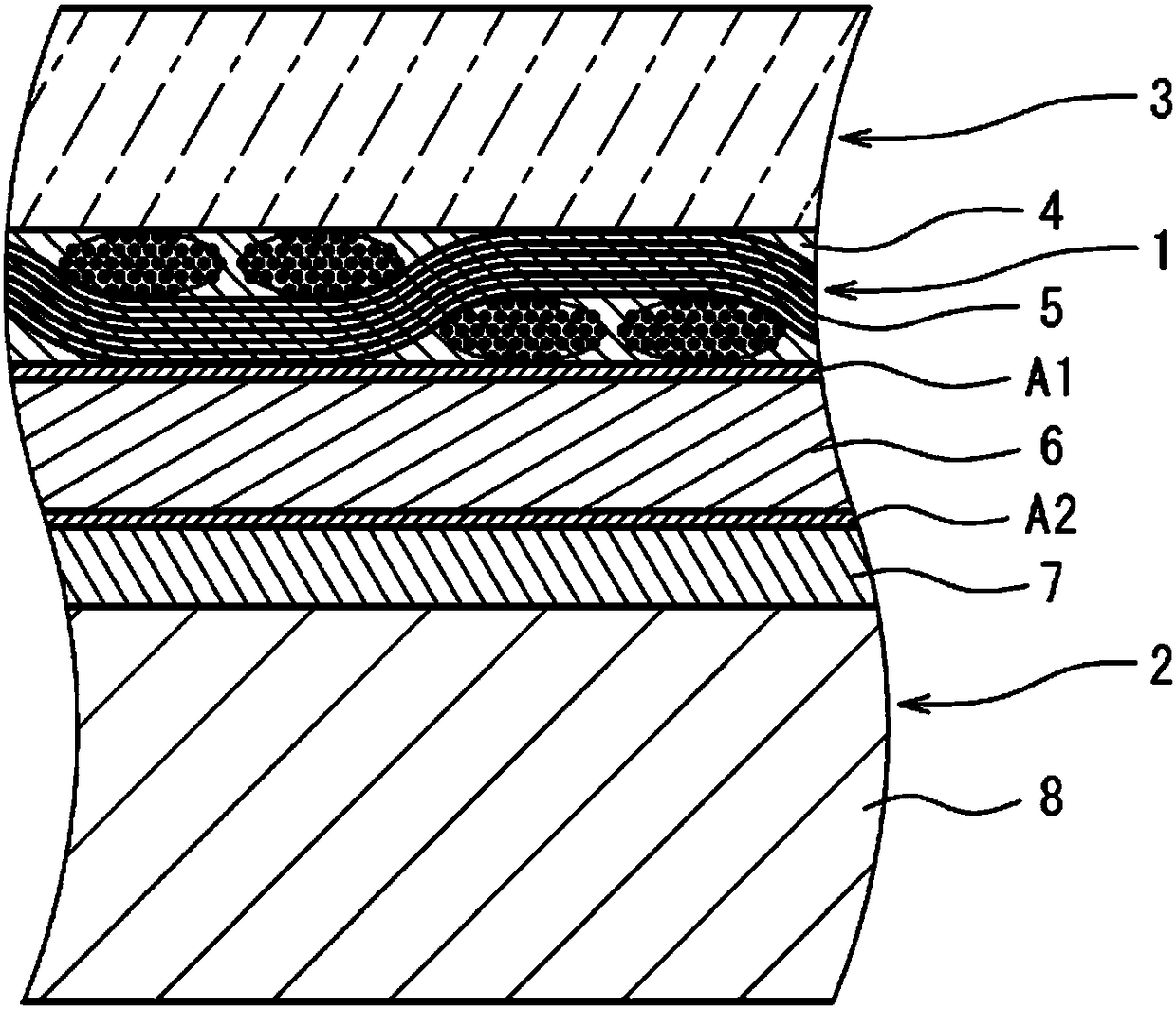

[0110] A molded product including the FRP sheet including a...

Embodiment

[0116] The present invention is described in detail below through examples, but the present invention should not be limitedly interpreted based on the description of the examples.

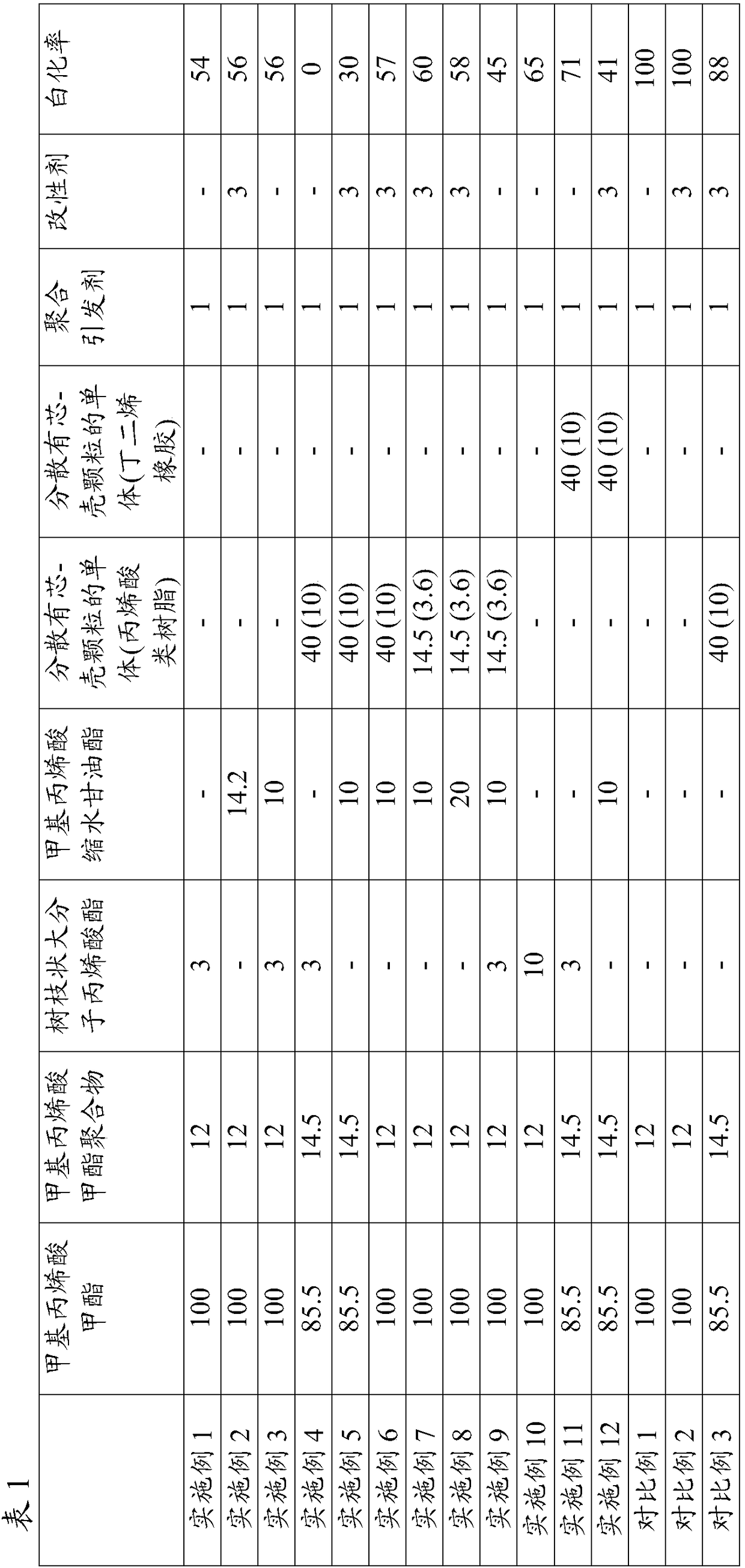

[0117] Resin composition for FRP

[0118] In order to verify the effect of the present invention, the resin compositions for FRP of Examples 1-12 and Comparative Examples 1-3 were prepared by using the respective components in the proportions shown in Table 1 (expressed in parts by mass).

[0119] As the methyl methacrylate, "Light Ester M" (Kyoeisha Chemical Co., Ltd.) was used. As the methyl methacrylate polymer, "SR8500" (Asahi Kasei Corporation) was used. As the dendrimer acrylate, "Viscoat #1000" (Osaka Organic Chemical Industry Ltd.) was used. As glycidyl methacrylate, "Light Ester G" (Kyoeisha Chemical Co., Ltd.) was used. As particles containing an acrylic resin as a main component in its surface layer, monomer "IBOA-MB302" (containing acrylic resin as a core) or "IBOA-MB602" (containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com