Petroleum drilling rig/workover rig equipment integrity management method and system

A management method and integrity technology, applied in data processing applications, instruments, calculations, etc., can solve the problems of equipment and facility maintenance decision-making, maintenance optimization risk assessment, and risk control lack of systematic and targeted technologies and systems, etc., to achieve Promote the production safety of the industry, reduce the production cost of enterprises, and improve the reliability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

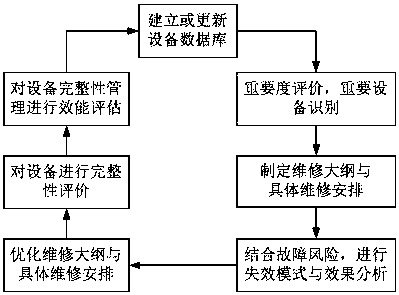

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

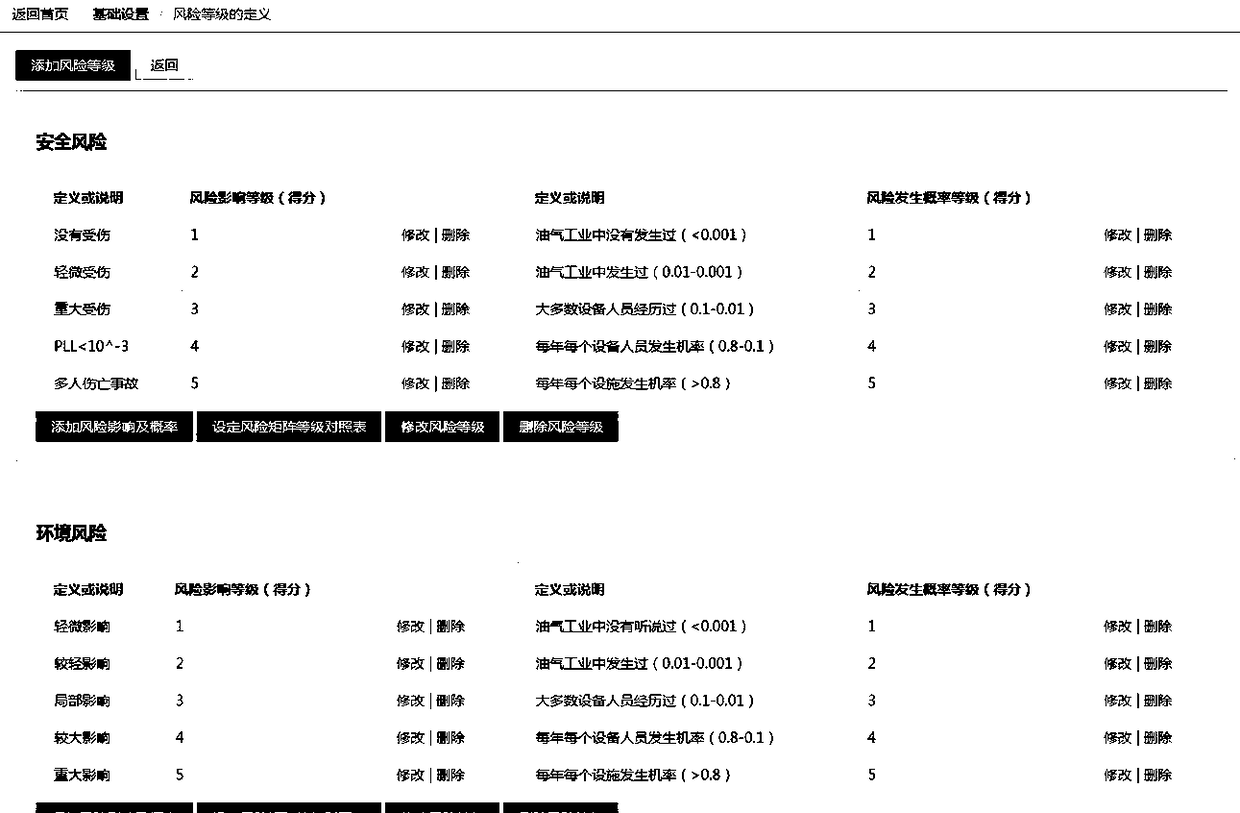

[0041] An oil drilling and repairing machine equipment integrity management system, mainly including equipment basic data storage module, importance evaluation module, failure risk analysis module, failure mode failure mode, impact and hazard analysis module, maintenance plan management module, integrity evaluation module module, performance evaluation module.

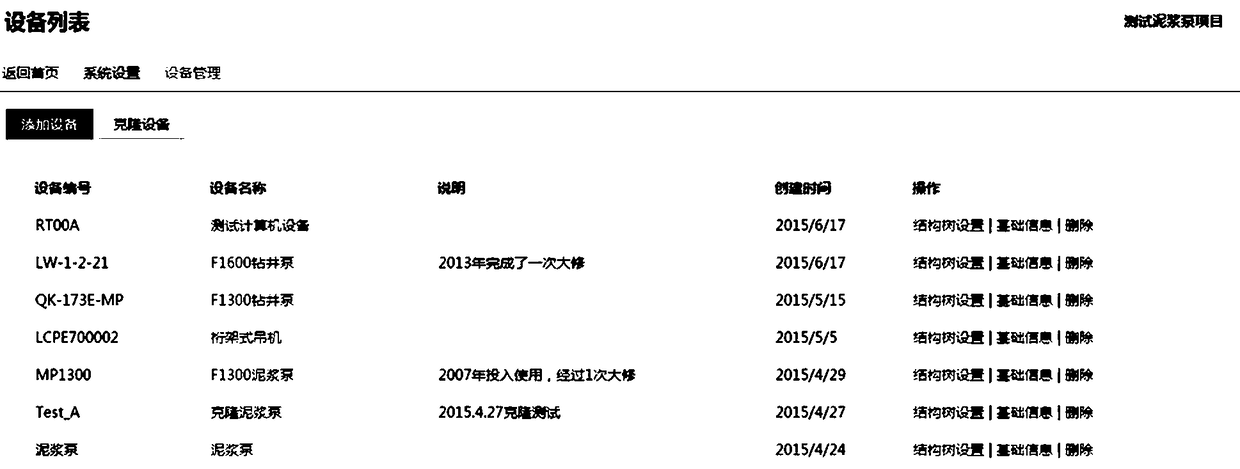

[0042] Equipment basic data storage module, interface as attached figure 2 As mentioned above, various data need to be collected and preserved, including design drawings, manufacturing documents, installation records, maintenance records, accident records, statutory inspection reports, evaluation reports, etc. At the same time, standardize the information records and da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com