Direct current brushless motor simulation device and control method thereof

A brushless DC motor and simulation equipment technology, which is applied in simulators, general control systems, motor generator testing, etc., can solve the problems of non-existence of energy interaction, failure to verify the durability and reliability of drive hardware, and achieve guaranteed simulation The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

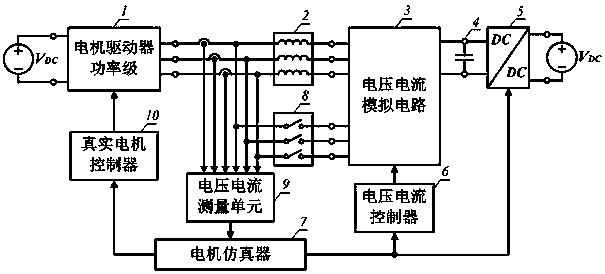

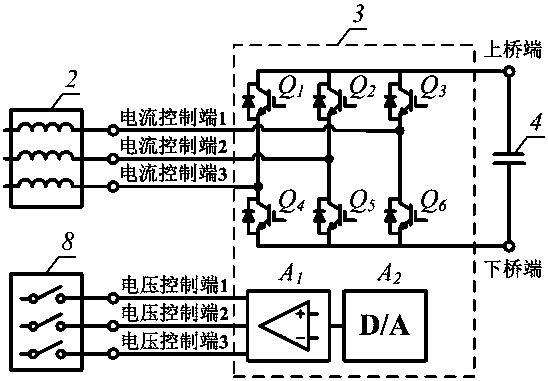

[0053] figure 1 Shown is the system architecture of the brushless DC motor simulation device of the present invention, including a motor driver power stage (1), a load simulation inductor (2), a voltage and current simulation circuit (3), a bus capacitor (4), a DC-DC module ( 5), a voltage and current controller (6), a motor emulator (7), a circuit opening and closing device (8), a voltage and current measurement unit (9) and a real motor controller (10), characterized in that:

[0054] In terms of circuit topology, the output end of the motor driver power stage (1) is connected to one end of the load simulation inductor (2), and the other end of the load simulation inductor (2) is connected to the current control circuit of the voltage and current simulation circuit (3). The output end of the motor driver power stage (1) is connected to one end of the circuit switching device (8), and the other end of the circuit switching device (8) is connected to the voltage of the voltage...

Embodiment 2

[0062] See figure 1 , Figure 5 and Figure 6 , the control method of the DC brushless motor simulation equipment includes 1), the function of the motor emulator (7) is to solve the DC brushless motor model of known motor parameters in real time, solve the motor state quantity and pass it to the voltage and current control The controller (6) is used to control the voltage and current, and at the same time, the state quantity of the motor is transmitted to the real motor controller (10) for the closed-loop control of the real motor, and to solve the voltage command of the DC-DC module (5); 2), the The voltage and current controller (6) receives the motor state quantity solved by the motor emulator (7) as the command value of the motor simulation, and controls the voltage and current simulation circuit (3) to output the desired voltage and current through the voltage and current tracking algorithm.

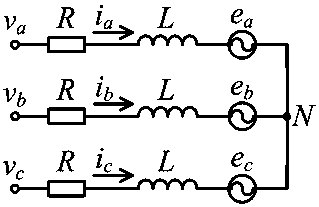

[0063] The motor emulator (7) includes a motor simulation algorithm, the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com