Unhulled rice dryer

A paddy dryer and frame technology, which is applied in the direction of dryer, drying, grain drying, etc., can solve the problems of easy mildew of rice, high production cost, high use cost, etc., and achieve simple structure and low production cost , the effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

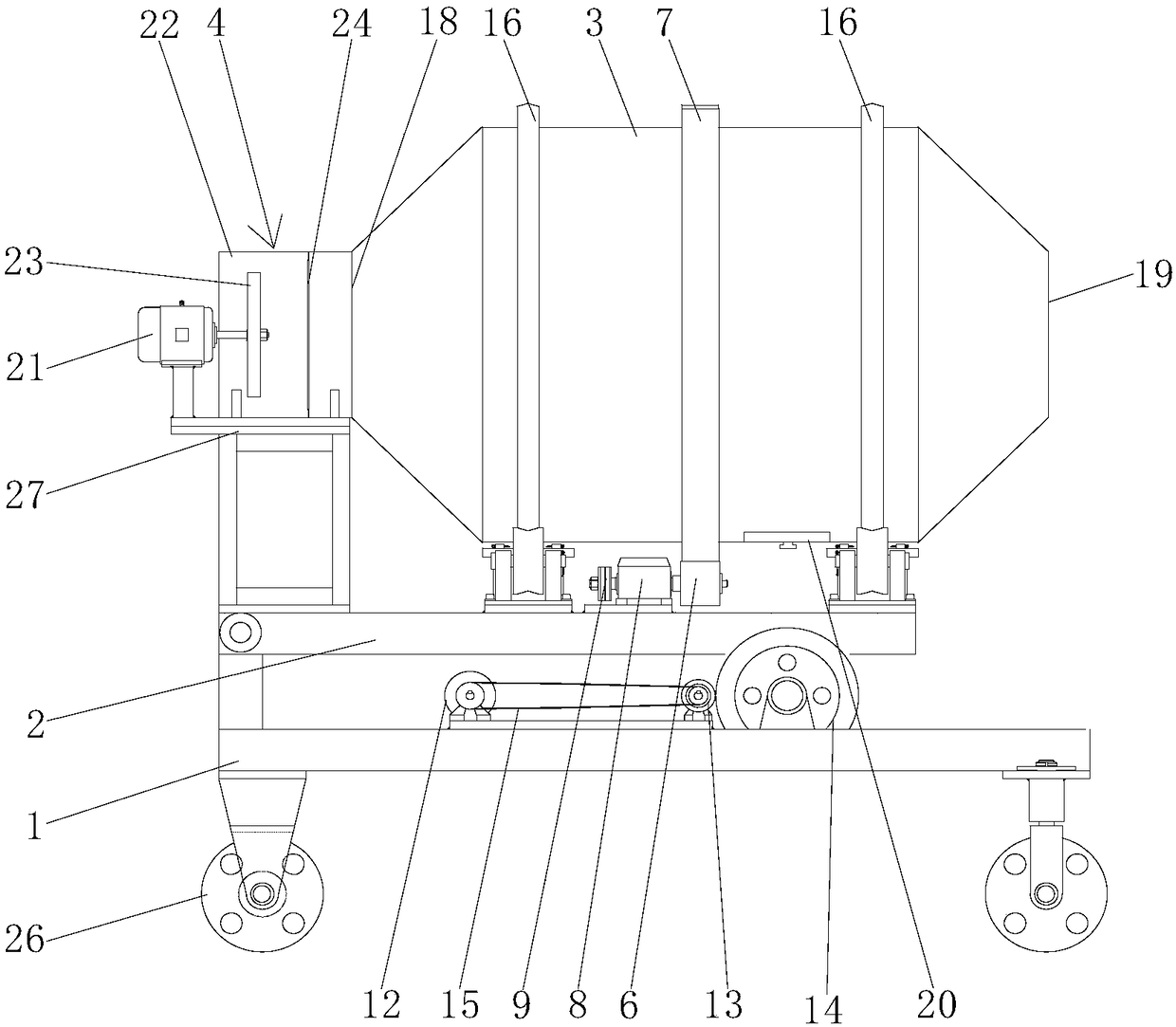

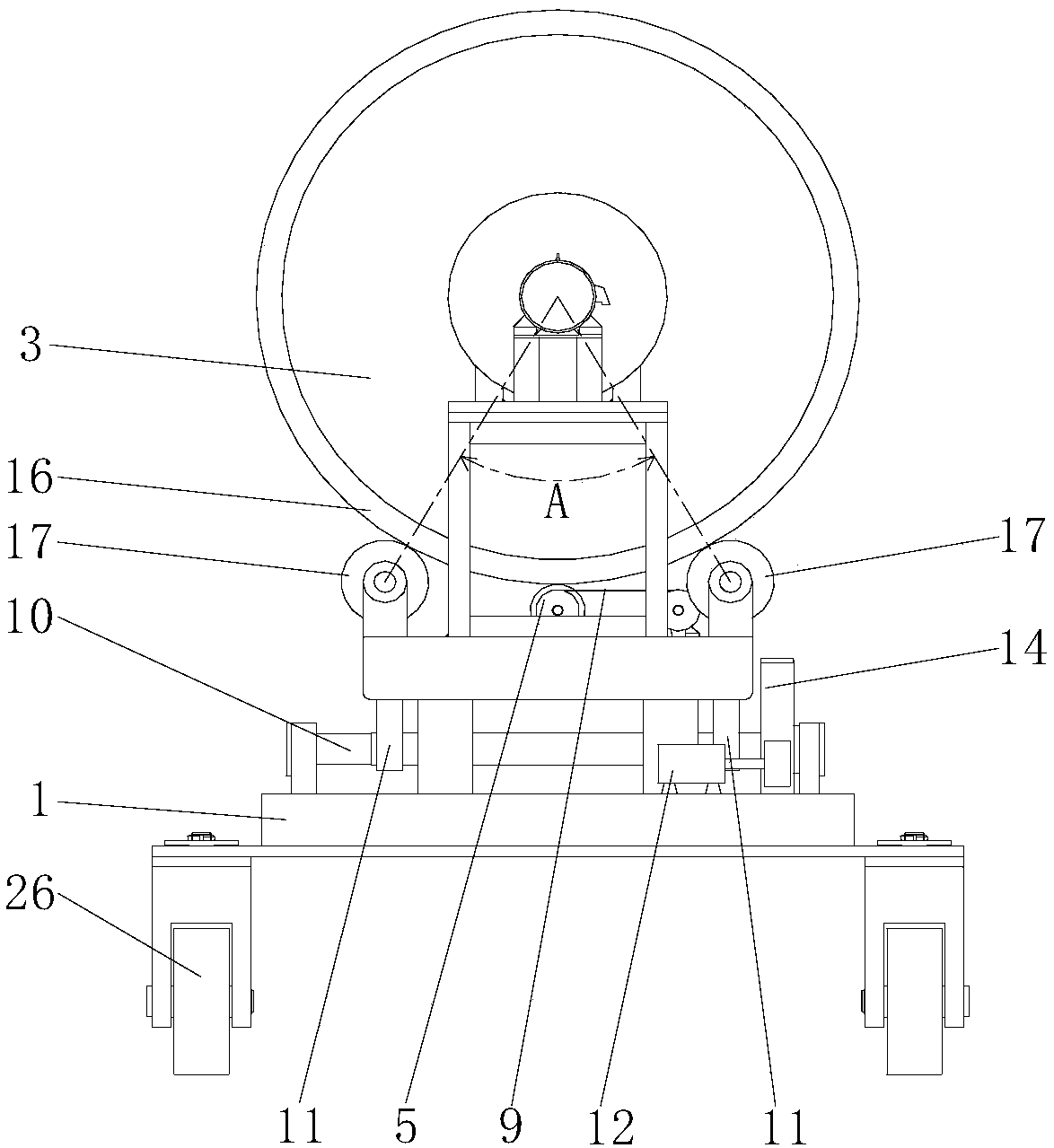

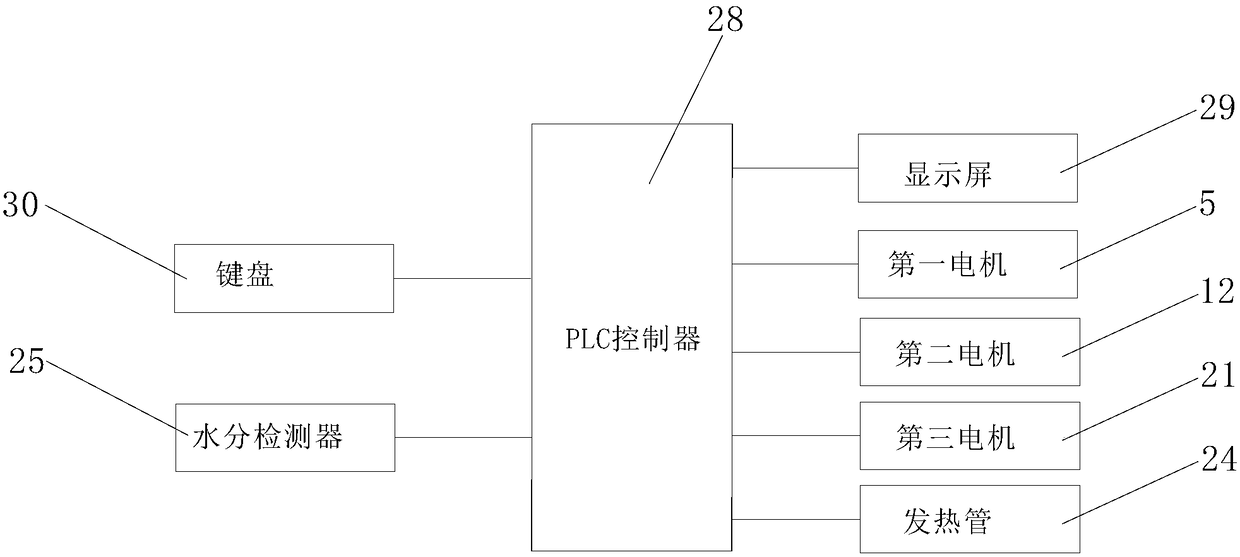

[0027] refer to Figure 1-3 , a paddy dryer, comprising a first frame 1, a second frame 2 positioned above the first frame 1, a drum 3 for drying paddy, a first power assembly for driving the drum 3 to rotate, A hot air mechanism 4 for providing hot air to the drum 3. One end of the second frame 2 is hinged to the first frame 1, and the other end is provided with a lifting mechanism for driving the second frame 2 to swing up and down. The hot air mechanism 4 and the drum 3 It is horizontally arranged on the second frame 2; the rice dryer also includes a control system for controlling the automatic operation of the drum 3 and the hot air mechanism 4, by using the control system to control the hot air mechanism 4 to provide hot air to the drum 3 and to control the rotation of the drum 3 to realize rice drying. Dry, easy to use, no pollution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com