Desorption desorbed gas processing device and method

A technology of treatment device and treatment method, applied in gas treatment application, gas treatment/storage purpose, combustion method, etc., can solve the problems of small desorption gas volume, incomplete combustion, uneconomical combustion device, etc., to avoid potential safety hazards and achieve The effect of energy reuse and pollution expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

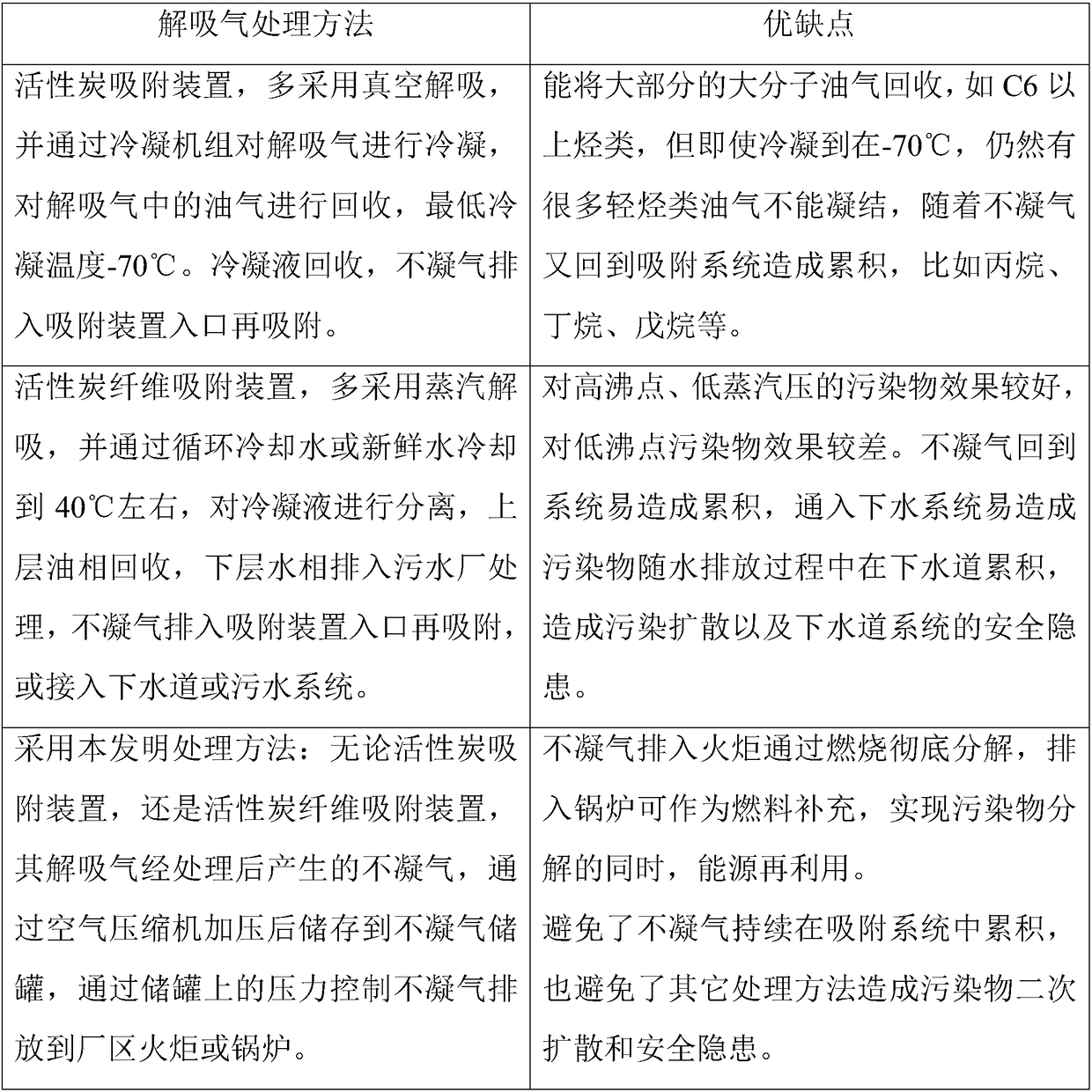

[0031] The existing waste gas treatment method discharges to the front end of the adsorption tower for adsorption, resulting in low treatment efficiency of the waste gas device and the phenomenon that the tail gas does not meet the standard; the desorption tail gas is introduced into the sewer or sewage system without degrading pollutants, which expands the scope of odor pollution.

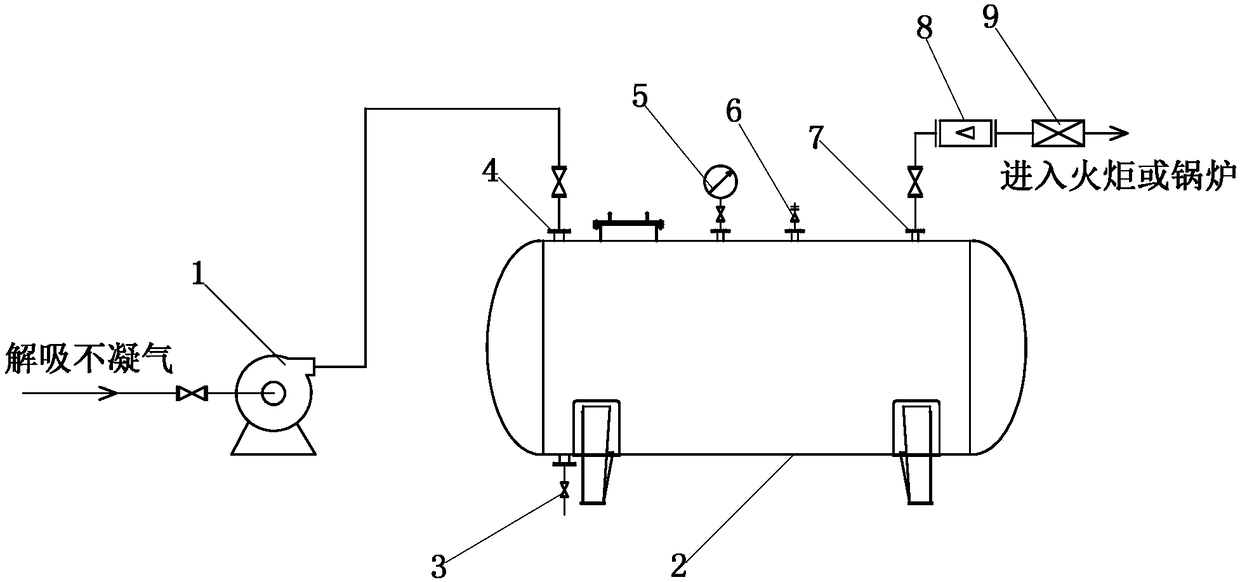

[0032] Such as figure 1 As shown, the desorption and desorption gas treatment device provided by the embodiment of the present invention includes: an air compressor 1, a non-condensable gas storage tank 2, a sewage outlet 3, a feed port 4, a pressure gauge 5, a safety valve 6, and a discharge port 7. Flow meter 8, flame arrester 9.

[0033] The air compressor 1 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com