Intelligent load relieving device

An intelligent and mitigation technology, applied in the load mitigation system and structural engineering fields, can solve the problems of large seasonal temperature difference, small mitigation range, and low line fault troubleshooting efficiency, and achieve energy saving, large mitigation range, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

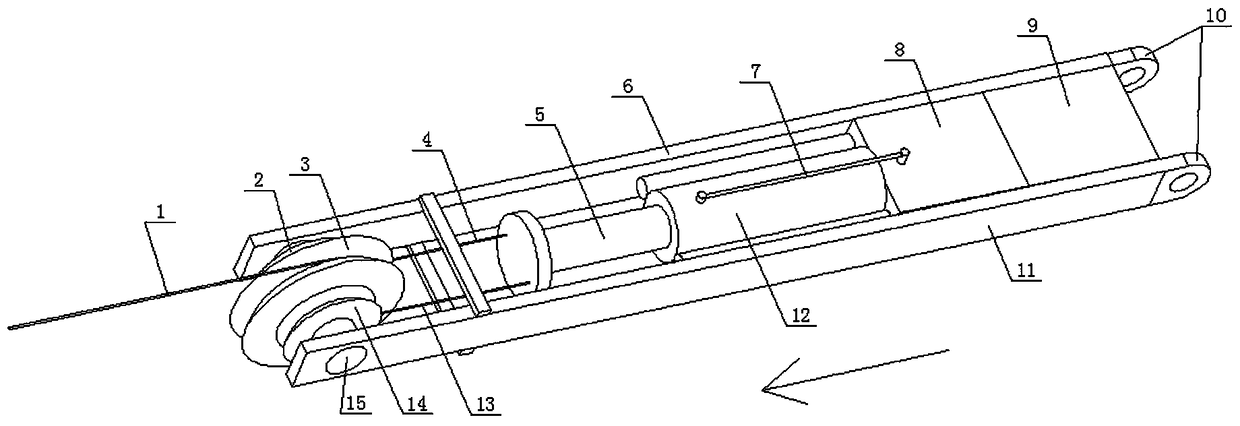

[0017] Such as figure 1 As shown, an intelligent load mitigation device includes a support frame composed of the left main frame side plate 11, the right main frame side plate 6 and intermediate connectors, and in the support frame from the front end to the rear end, that is, along the direction of the arrow A Roller mechanism, air cylinder 12, air pump 8 and accumulator 9 are installed successively, and the piston rod 5 of described air cylinder 12 is arranged toward the direction of roller mechanism, and described roller mechanism comprises rotating shaft 15, and driving pulley 3, The first buffer pulley 2 and the second buffer pulley 14, the first buffer pulley 2 and the second buffer pulley 14 are distributed on both sides of the drive pulley 3, and the two ends of the rotating shaft 15 are respectively connected to the corresponding left main frame side plate 11 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com