An atmosphere protective cover for electroslag furnace and electroslag furnace smelting system

A protective cover and electroslag furnace technology, applied in the field of atmosphere protective cover and electroslag furnace smelting system, atmosphere protective cover, can solve the problems of easy formation of eddy current, difficult alignment of electrode holes, lack of atmosphere protective cover, etc., to improve efficiency And the effect of high quality and smelting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

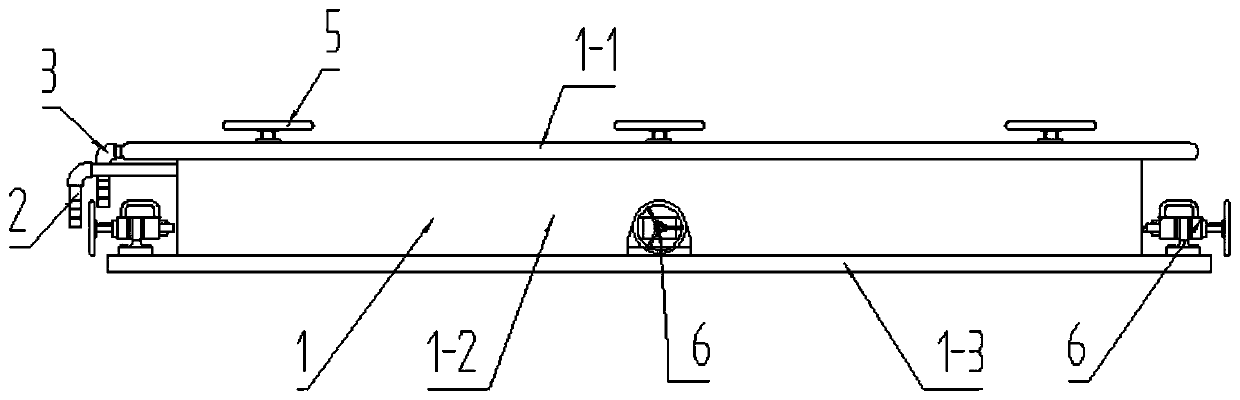

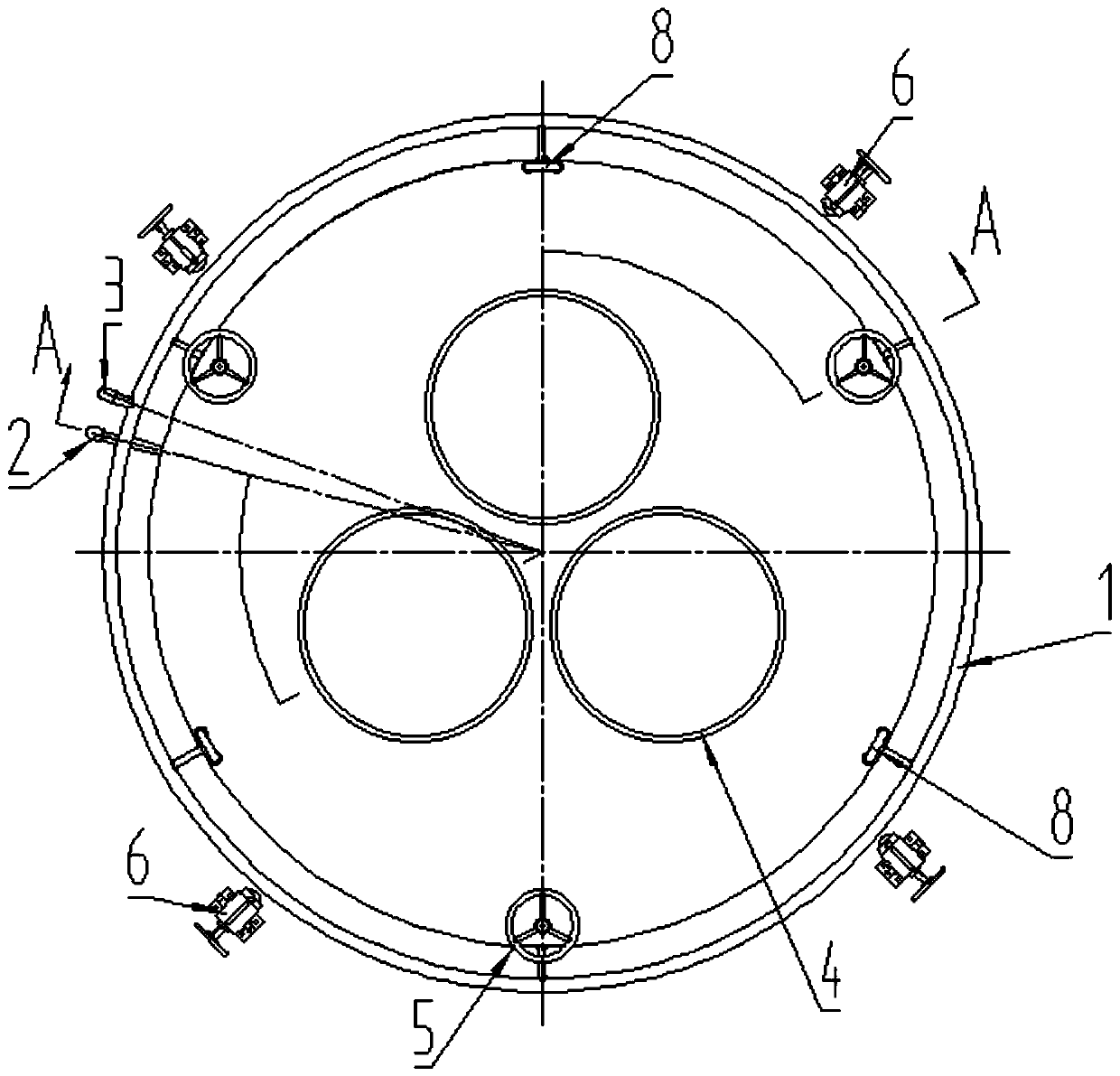

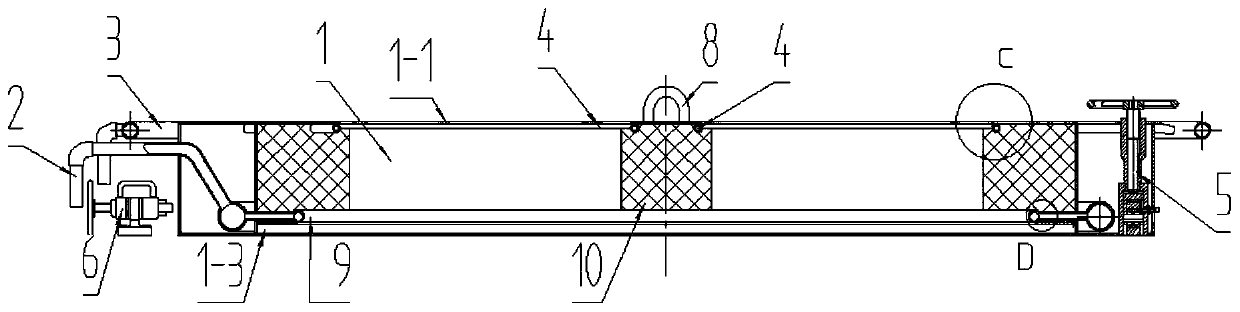

[0047] like Figure 1-Figure 11 As shown, an atmosphere protective cover for an electroslag furnace includes a housing 1, and the housing 1 is provided with 3 through holes for electrode installation;

[0048] The housing 1 is cylindrical, and the housing 1 includes a circular cylinder 1-2, a cover plate 1-1 arranged above the circular cylinder 1-2 and a cover plate arranged on the circular cylinder 1-2. The bottom plate 1-3 below the body 1-2, the cover plate 1-1 is provided with three electrode blowing rings 4, the electrode blowing rings 4 correspond to the electrode installation through holes one by one, the electrode The blowing ring 4 is surrounded by pipe fittings, and the pipe fittings are steel pipes; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com