Quenched workpiece self-rotation mechanism in full-automatic carrier roller quenching production line

A rotating mechanism and fully automatic technology, applied in quenching devices, manufacturing tools, furnaces, etc., can solve problems affecting the strength and quality of bearing rings, deformation, etc., to achieve the effect of solving uneven temperature and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

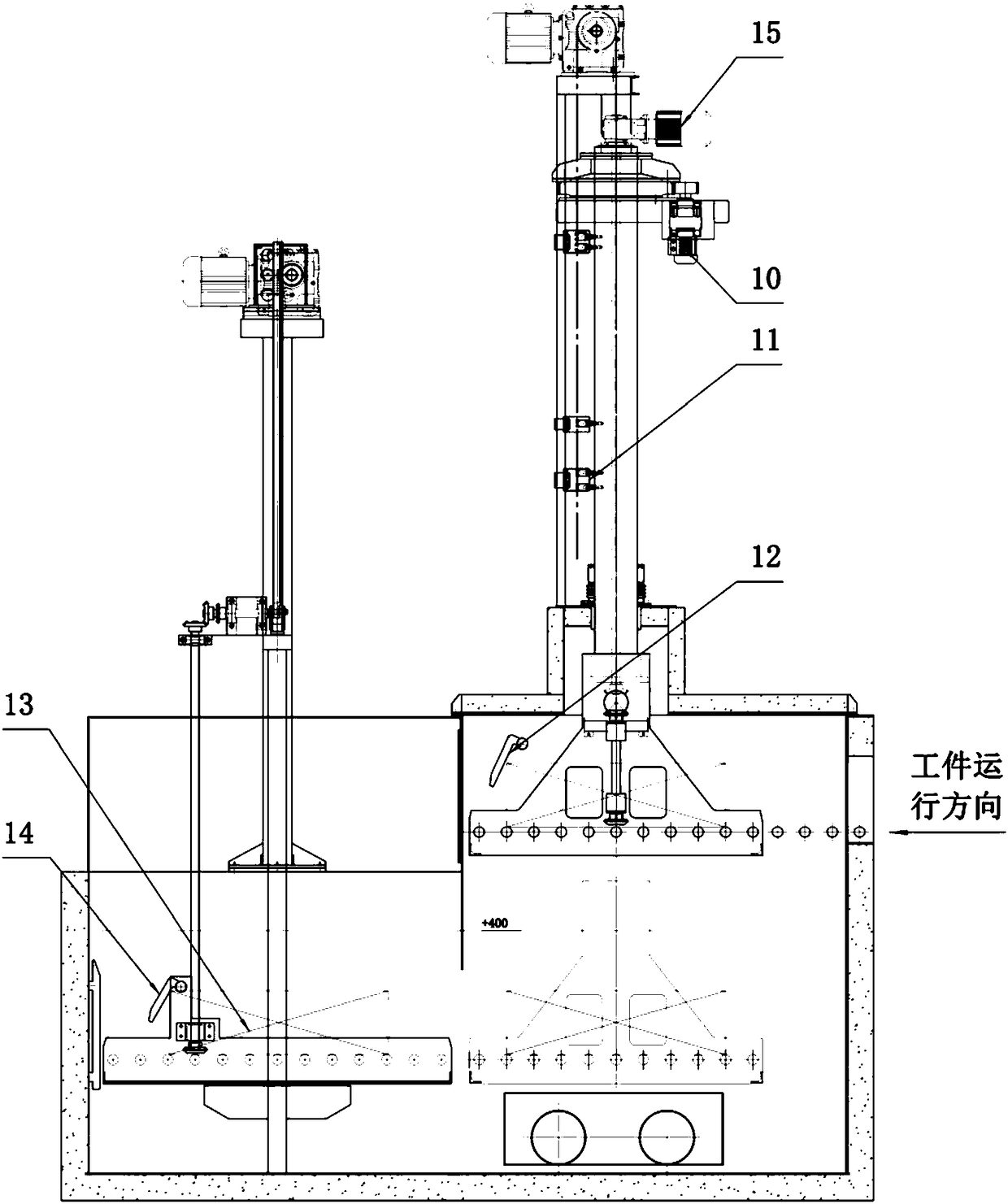

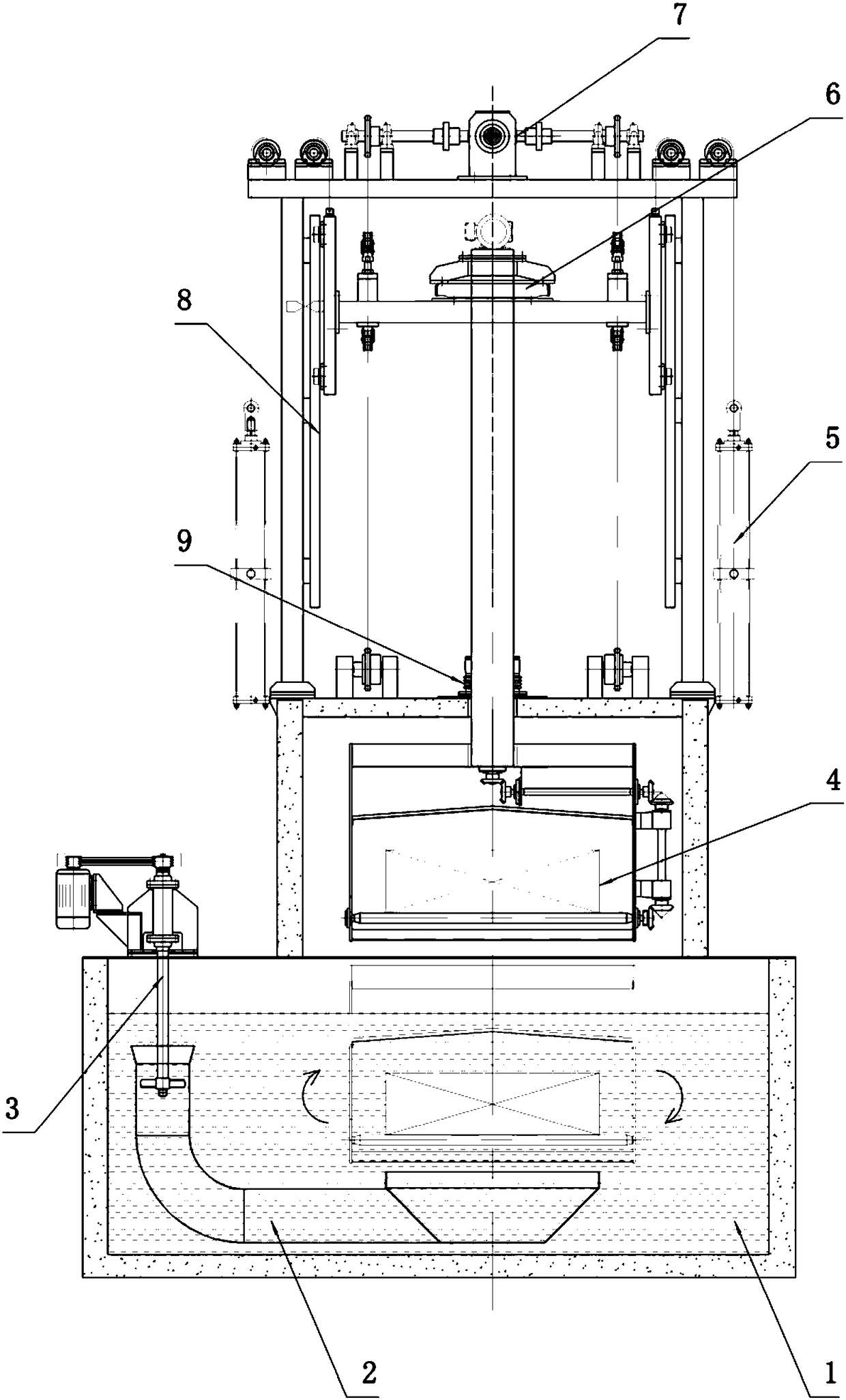

[0013] Embodiment: As shown in the accompanying drawings, the self-rotating mechanism of the quenched workpiece in this fully automatic idler quenching production line mainly includes a nitrate quenching tank 1, a draft tube 2, a stirring mechanism 3, a balancing device 5, a rotating mechanism 6, Lifting mechanism A7, guiding device 8, sealing device 9, servo motor 10, limit switch A11, limit switch B12, lifting mechanism B13, limit switch C14, driving mechanism 15, the lifting mechanism is installed side by side in the nitrate quenching tank 1 B13 and lifting mechanism A7, both sides of lifting mechanism B13 and lifting mechanism A7 are equipped with balance device 5 to maintain balance and guide device 8 to guide and limit, drive mechanism 15 and rotating mechanism 6 are installed under lifting mechanism A7, and rotating mechanism 6 drives the workpiece 4 rotation, the driving mechanism 15 transfers the workpiece 4 to the lifting mechanism B13, the limit switch B12 is set on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com