Method for preparing 5-hydroxymethylfurfural by degrading cellulose in formic acid/acetic acid system

A technology for hydroxymethylfurfural and cellulose degradation, applied in the field of chemical engineering, can solve the problems of high cost, inconvenient industrialization, and high cost, and achieve the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing 5-hydroxymethylfurfural by degrading cellulose in a formic acid / acetic acid system, comprising the steps:

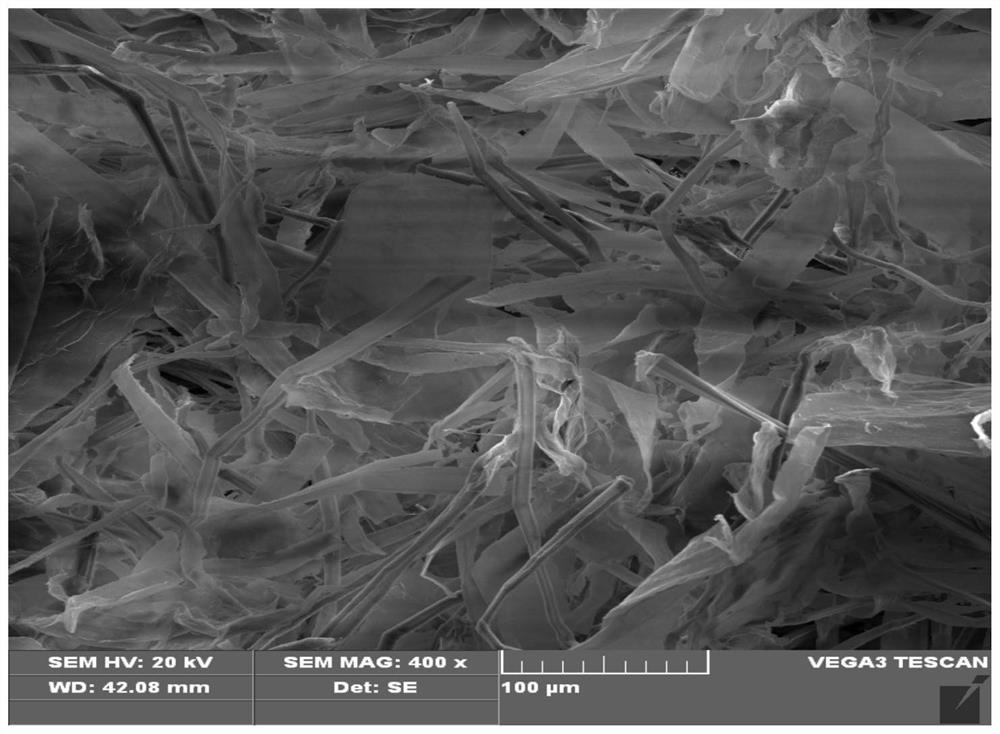

[0039] Step 1, pretreatment of cellulose

[0040] Weigh 1g of cellulose and put it into a 100ml beaker, then add 30ml of distilled water to the beaker and mix evenly, then use an ultrasonic cell pulverizer to sonicate at a power of 600W, set the ultrasonic working mode to 12s (ultrasonic 8s, intermittent 4s), ultrasonic Stop after 8 minutes to obtain ultrasonically pretreated cellulose, and freeze-dry the ultrasonically pretreated cellulose at -40°C for 24 hours before use;

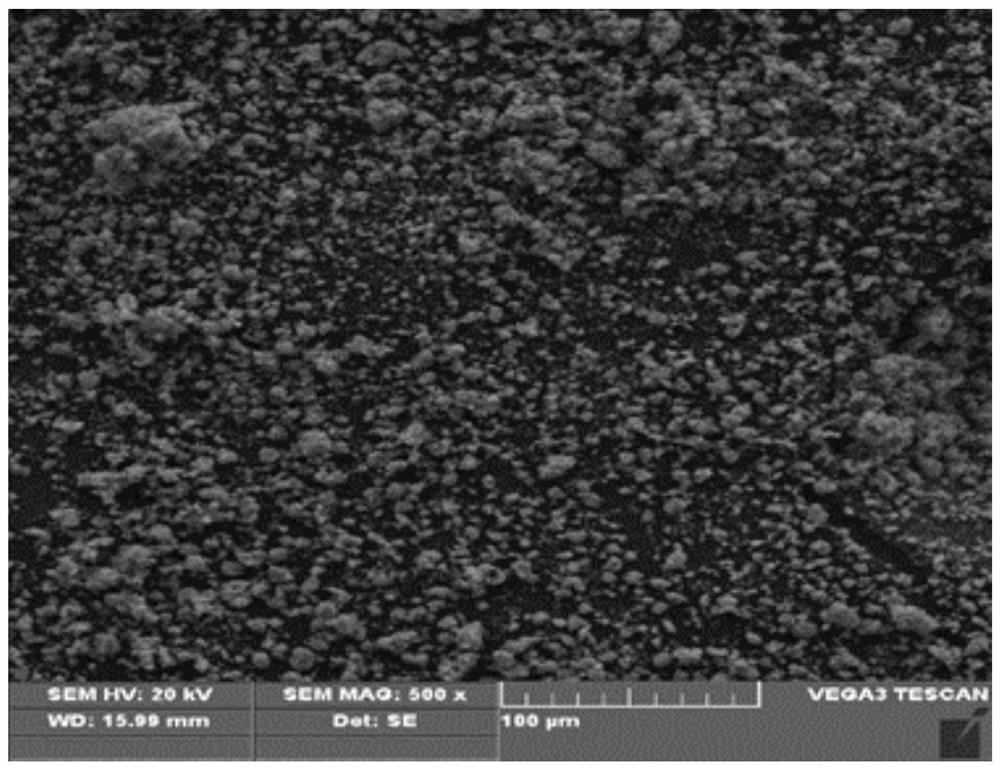

[0041] Step 2, SO 42- / TiO 2 Preparation of solid acid catalyst

[0042] Step 2.1, weigh 1g of nano-titanium dioxide powder and pour it into a beaker, then add 30ml of sulfuric acid with a concentration of 3mol / L to the beaker, stir for 5min and let it stand for 20h, after standing, use a sand filter to filter out the sulfuric acid solution to obtain sulfuric acid tr...

Embodiment 2

[0047] A method for preparing 5-hydroxymethylfurfural by degrading cellulose in a formic acid / acetic acid system, comprising the steps:

[0048] Step 1, pretreatment of cellulose

[0049] Weigh 2g of cellulose and put it into a 100ml beaker, then add 50ml of distilled water to the beaker and mix evenly, then use an ultrasonic cell pulverizer to sonicate at a power of 800W, set the ultrasonic working mode to 12s (ultrasonic 8s, intermittent 4s), ultrasonic Stop after 10 minutes to obtain ultrasonically pretreated cellulose, freeze-dry the ultrasonically pretreated cellulose at -45°C for 24 hours before use;

[0050] Step 2, SO 4 2- / TiO 2 Preparation of solid acid catalyst

[0051] Step 2.1, weigh 2g of nano-titanium dioxide powder and pour it into a beaker, then add 50ml of sulfuric acid with a concentration of 3mol / L to the beaker, stir for 8min and then let it stand for 20h. Nano-titanium dioxide; dry the sulfuric acid-treated nano-titanium dioxide in a vacuum oven at 1...

Embodiment 3

[0056] A method for preparing 5-hydroxymethylfurfural by degrading cellulose in a formic acid / acetic acid system, comprising the steps:

[0057] Step 1, pretreatment of cellulose

[0058] Weigh 3g of cellulose and put it into a 100ml beaker, then add 60ml of distilled water to the beaker and mix evenly, then use an ultrasonic cell pulverizer to sonicate at a power of 900W, set the ultrasonic working mode to 12s (ultrasonic 8s, intermittent 4s), ultrasonic Stop after 12 minutes to obtain ultrasonically pretreated cellulose, freeze-dry the ultrasonically pretreated cellulose at -50°C for 36 hours before use;

[0059] Step 2, SO 4 2- / TiO 2 Preparation of solid acid catalyst

[0060] Step 2.1, weigh 3g of nano-titanium dioxide powder and pour it into a beaker, then add 60ml of sulfuric acid with a concentration of 3mol / L to the beaker, stir for 8min and then let it stand for 24h. After standing, use a sand filter to remove the sulfuric acid solution to obtain sulfuric acid tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com