Method used for treating high arsenic waste water

A waste water and solution technology, which is applied in the direction of precipitation treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of poor treatment effect and poor stability of high-arsenic wastewater, and achieve high arsenic removal rate and no secondary Less pollution, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a method for mineral synergistic and stable treatment of high-arsenic wastewater, the specific process is as follows:

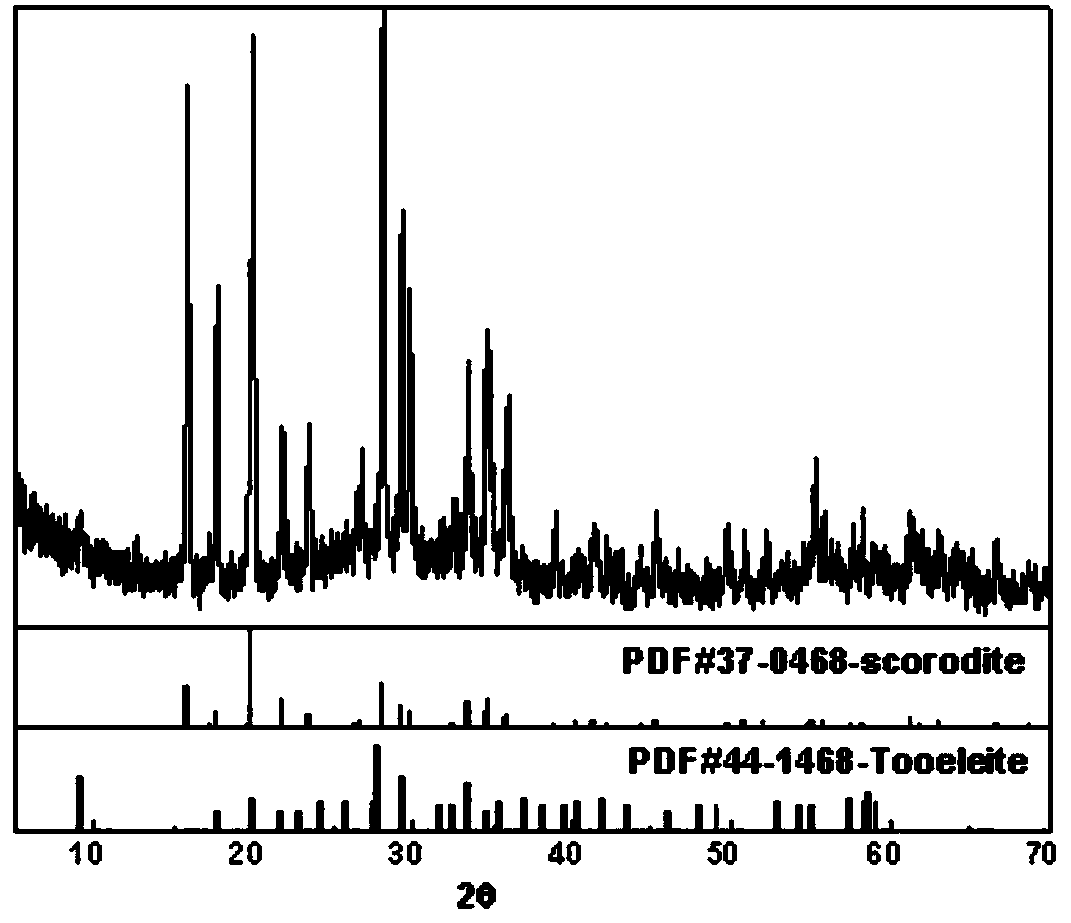

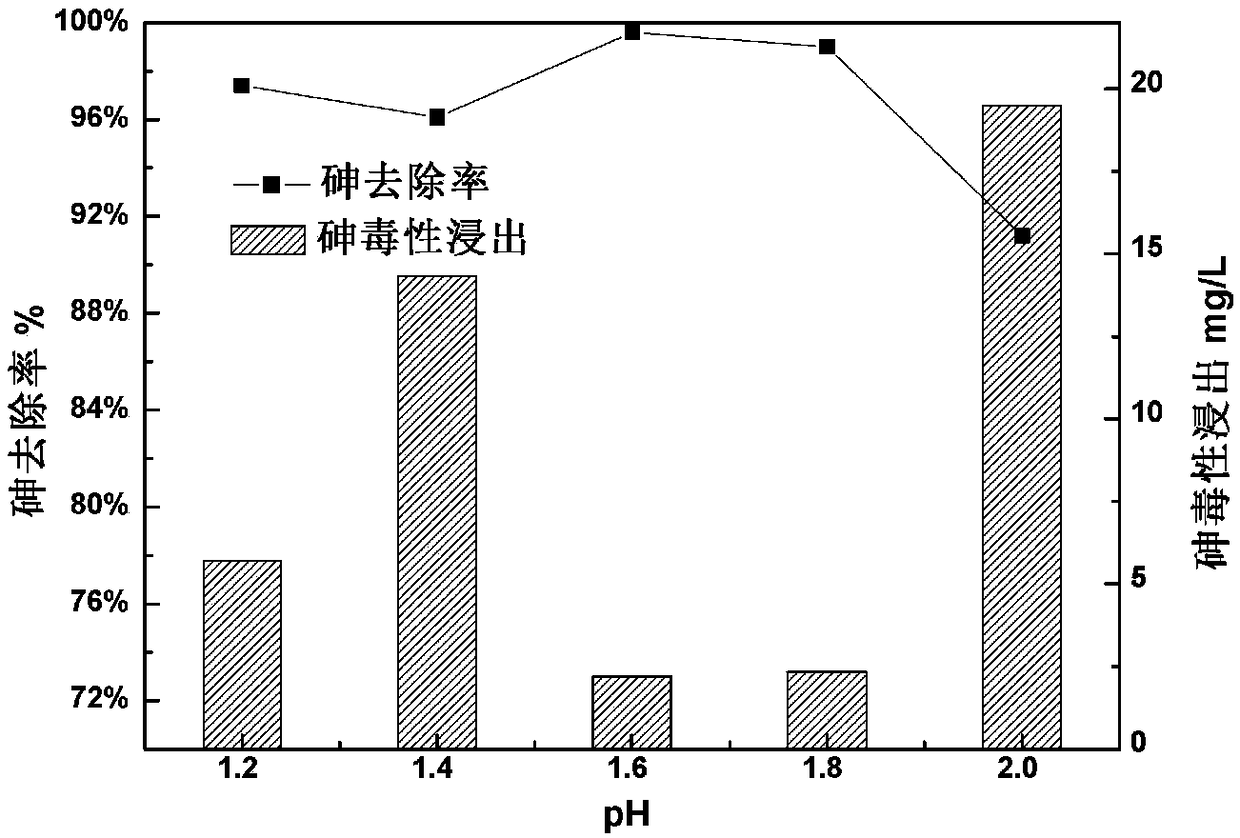

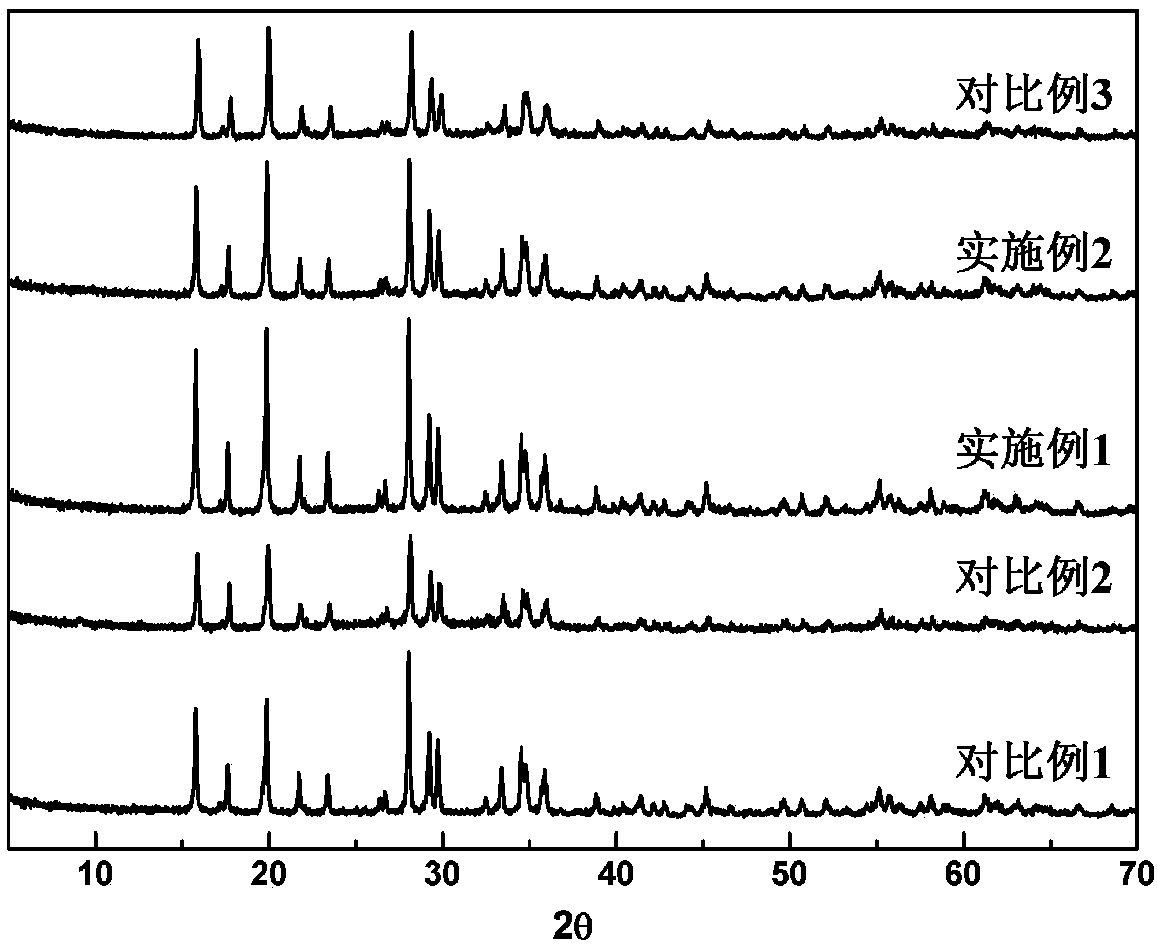

[0027] Arsenous acid, ferric nitrate and sodium sulfate were used as raw materials to prepare As 3+ Arsenic-containing solution with a concentration of 15g / L (calculated as arsenic), Fe 3+ Concentration of 16.8g / L iron salt solution and SO 4 2- The sulfate solution with a concentration of 4.8g / L is set aside; take 20ml respectively and mix well, then adjust the pH of the solution to 1.6 with NaOH. Pour this solution into a reaction kettle with a capacity of 100ml, put it into an oven, set the temperature at 165°C, and start timing when the temperature rises to the set temperature, react at this temperature for 8h, and cool naturally. The concentration of As in the supernatant was detected, and the removal rate of As was calculated to be 99.6%. At the same time, the mixed solution was vacuum-filtered with a 0.45 μm filter mem...

Embodiment 2

[0029] This embodiment provides a method for mineral synergistic and stable treatment of high-arsenic wastewater, the specific process is as follows:

[0030] Arsenous acid, ferric nitrate and sodium sulfate were used as raw materials to prepare As 3+ Arsenic-containing solution with a concentration of 15g / L (calculated as arsenic), Fe 3+ Concentration of 16.8g / L iron salt solution and SO 4 2- The sulfate solution with a concentration of 4.8g / L is set aside; after taking 20ml and mixing well, adjust the pH of the solution to 1.8. Pour this solution into a reaction kettle with a capacity of 100ml, put it into an oven, set the temperature at 165°C, and start timing when the temperature rises to the set temperature, react at this temperature for 8 hours, and cool naturally. The concentration of As in the supernatant was detected, and the removal rate of As was calculated to be 99.1%. At the same time, the mixed solution was vacuum-filtered with a 0.45 μm filter membrane and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com