Method for preparing graphene and graphene

A graphene and graphene technology, applied in the field of materials, can solve the problems of large differences in G performance and failure to meet the requirements of electrochemical energy storage performance, etc., to achieve increased conjugation effects, reduced number of layers, and improved energy storage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of graphene provided by the present embodiment is made like this:

[0044] Weigh 1g of fully dried natural flake graphite and 1g NaNO 3 Mix in a container and inject 50mL of concentrated H 2 SO 4 , the whole system was magnetically stirred in an ice bath environment for 1 h. Then slowly add 5 g KMnO to the solution 4 , keep stirring for 2h, and keep the system temperature at 5°C. The temperature was then raised to 35 °C and stirring was continued for 2 h. After that, 100 mL of deionized water was slowly dropped into it, and the temperature was raised to 98 ° C. After 15 min, 240 ml of 60 ° C deionized water was added to the container again, followed by 10 mL of H 2 o 2 , after the solution turns from brown yellow to golden yellow, the reaction ends. Finally, the above product was diluted with deionized water, centrifuged at 12000 rpm for 15 min to retain the precipitate, and repeated 6 times. After the above solution was sonicated for 1 h, it was centrifu...

Embodiment 2

[0048] A kind of graphene provided by the present embodiment is made like this:

[0049] Weigh 1g of fully dried natural flake graphite and 1g NaNO 3 Mix in a container and inject 50mL of concentrated H 2 SO 4 , the whole system was magnetically stirred in an ice bath environment for 1 h. Then slowly add 5 g KMnO to the solution 4 , keep stirring for 2h, and keep the system temperature at 5°C. The temperature was then raised to 35 °C and stirring was continued for 2 h. After that, 100 mL of deionized water was slowly dropped into it, and the temperature was raised to 98 ° C. After 15 min, 240 ml of 60 ° C deionized water was added to the container again, followed by 10 mL of H 2 o 2 , after the solution turns from brown yellow to golden yellow, the reaction ends. Finally, the above product was diluted with deionized water, centrifuged at 12000 rpm for 15 min to retain the precipitate, and repeated 6 times. After the above solution was sonicated for 1 h, it was centrifuge...

Embodiment 3

[0053] A kind of Graphene provided by the present embodiment is made like this:

[0054] Weigh 1g of fully dried natural flake graphite and 1g NaNO 3 Mix in a container and inject 50mL of concentrated H 2 SO 4 , the whole system was magnetically stirred in an ice bath environment for 1 h. Then slowly add 5 g KMnO to the solution 4 , keep stirring for 2h, and keep the system temperature at 5°C. The temperature was then raised to 35 °C and stirring was continued for 2 h. After that, 100 mL of deionized water was slowly dropped into it, and the temperature was raised to 98 ° C. After 15 min, 240 ml of 60 ° C deionized water was added to the container again, followed by 10 mL of H 2 o 2 , after the solution turns from brown yellow to golden yellow, the reaction ends. Finally, the above product was diluted with deionized water, centrifuged at 12000 rpm for 15 min to retain the precipitate, and repeated 6 times. After the above solution was sonicated for 1 h, it was centrifu...

PUM

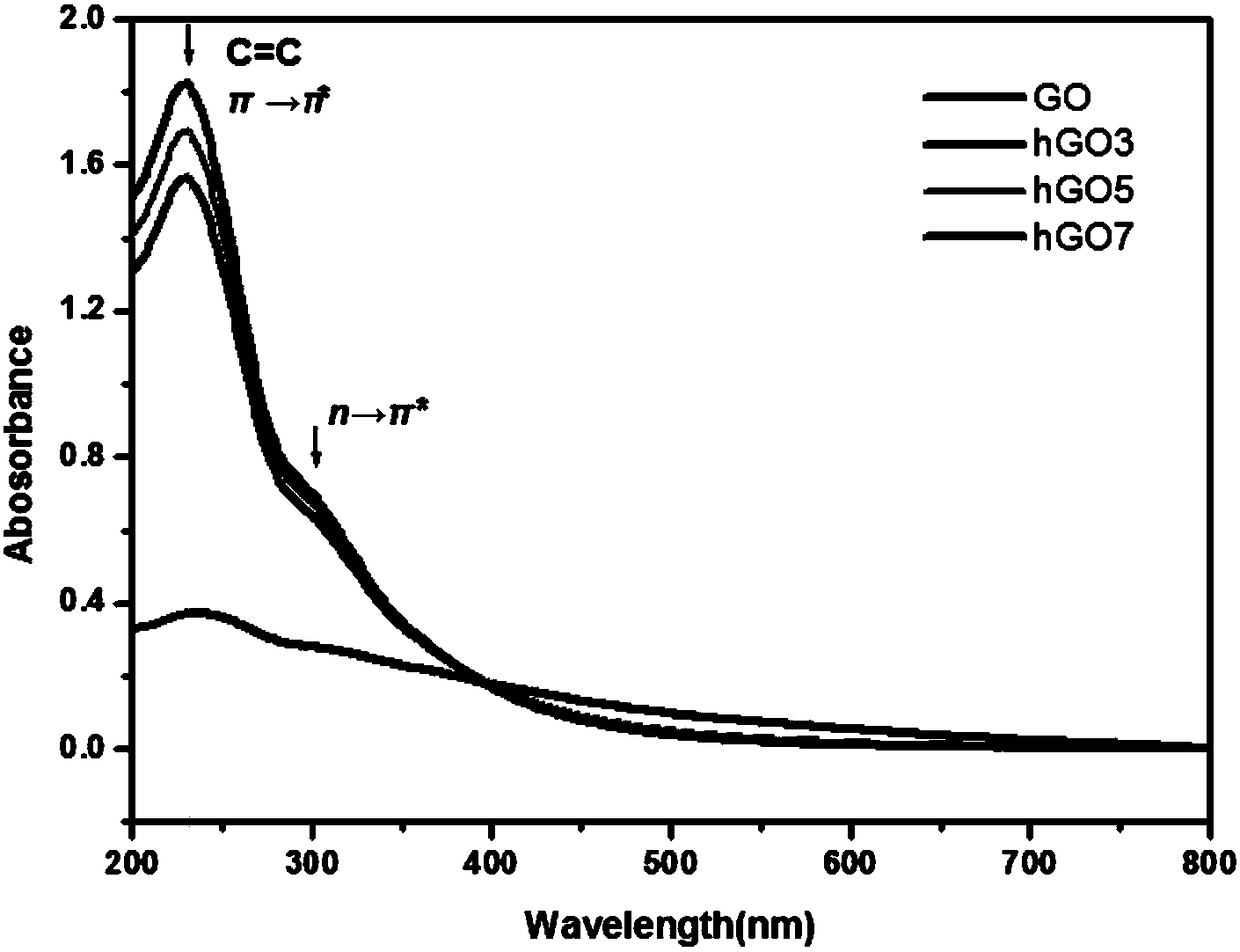

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com