Sulfur hexafluoride supplementary gas overhaul vehicle

A technology of sulfur hexafluoride and supplementary gas, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of not being able to meet the displacement of narrow gaps, not being able to move obliquely, complex and bulky structures, etc., to save manpower and operate The effect of convenience and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

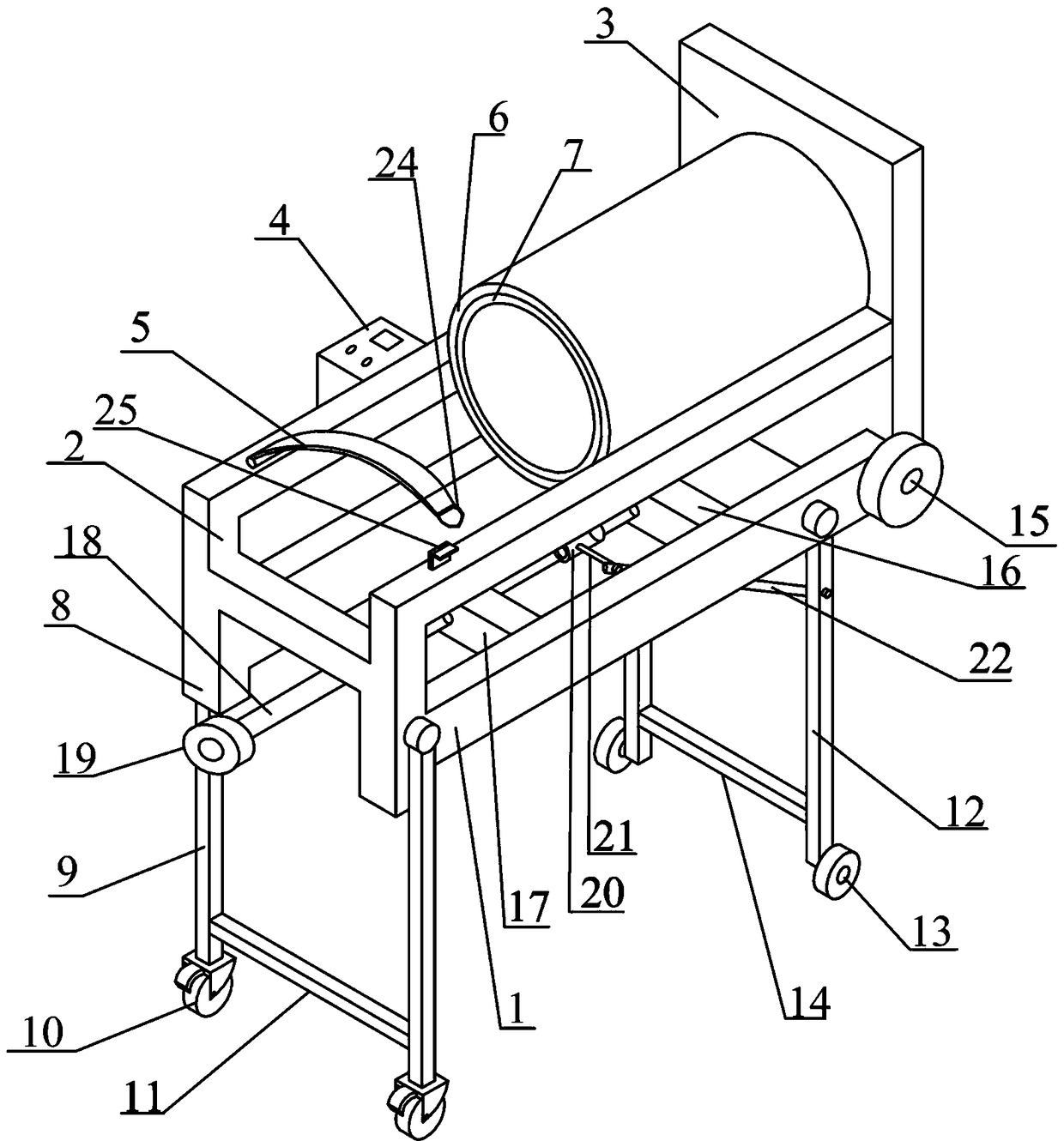

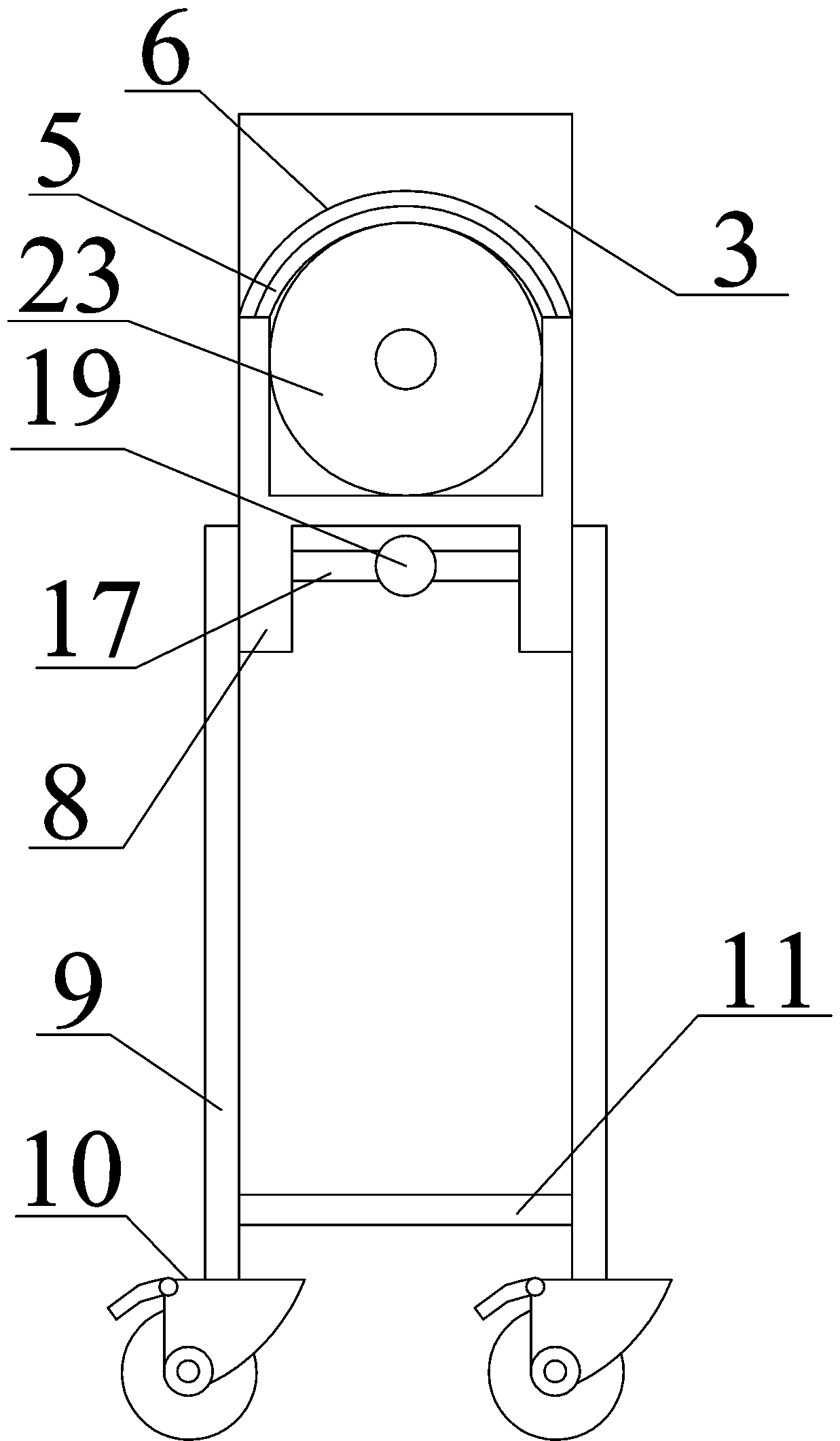

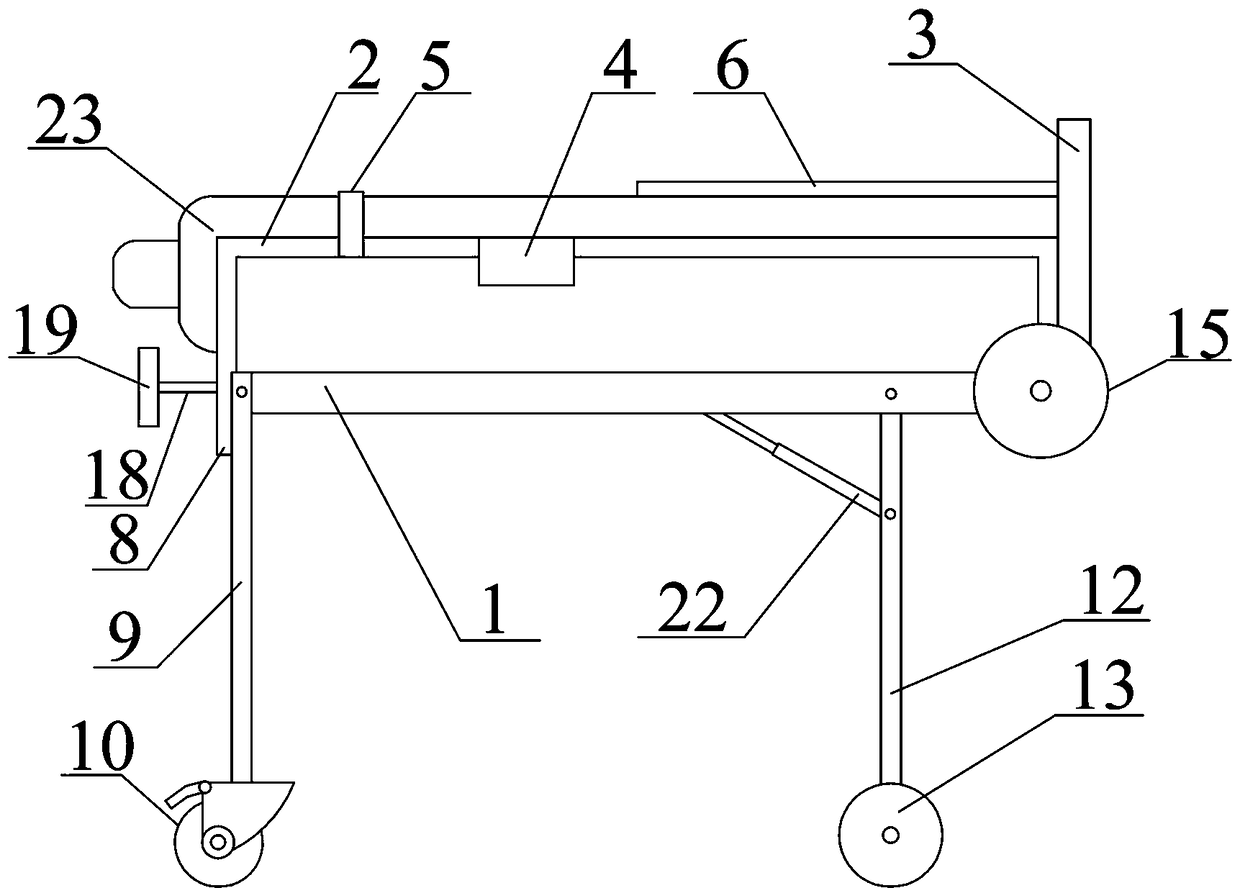

[0031] see Figure 1-5, a sulfur hexafluoride supplementary gas maintenance vehicle, including a frame, the frame includes a base and a bearing tank 2 that matches the shape of the gas cylinder 23, the bearing tank 2 is a frame structure, and the bearing tank 2 A load cell 3 is arranged at the bottom, and a display controller 4, a clip 5 and a heat preservation cover 6 matching the shape of the gas cylinder 23 are also arranged on the carrying tank 2, and the display controller 4 is electrically connected to the load cell 3 , the top of the carrying tank 2 is hinged to one end of the clip 5, the other end of the clip 5 is hinged to the hook 24, the top of the carrying tank 2 is provided with a buckle 25 matching the hook 24, and the heating cover 6 is provided device 7, the heating device 7 is a heating blanket; the base includes two vertical boards 1 symmetrically arranged on both sides of the bottom of the bearing tank 2, and a vertical handle 8 is provided at the end of the...

Embodiment 2

[0036] see Figure 6 , the structure of the sulfur hexafluoride supplementary gas maintenance vehicle in this embodiment is similar to that of the embodiment, and the similarities will not be repeated. Some differences are: the crank handle 26 is set on the runner 19, and the crank handle 26 is convenient for rotating the runner 19. An air drum 27 is also arranged on the outside of the vertical board 1, and the air drum 27 is used to shrink the air rope of the sulfur hexafluoride cylinder to keep the construction site clean.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com