Self-locking electric heating substrate for rail transit vehicles

A rail transit vehicle, self-locking technology, applied in the field of rail transit vehicle reliability, lightweight and safety, to achieve the effect of convenient and simple installation and disassembly, high reliability and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

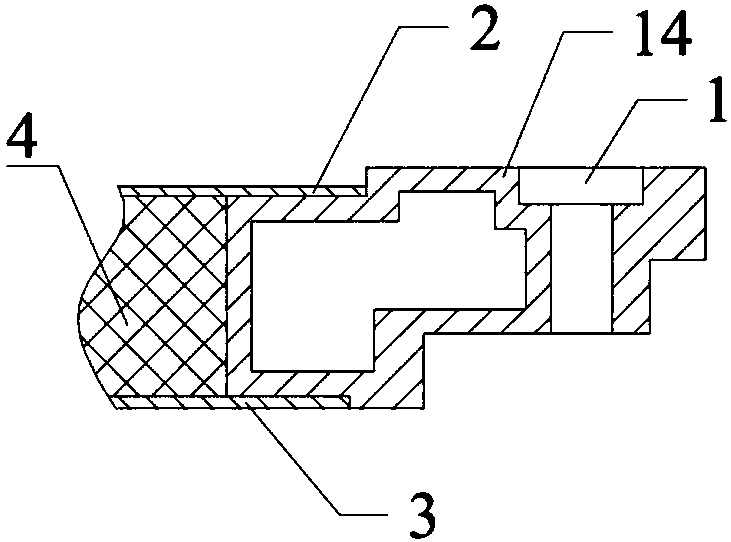

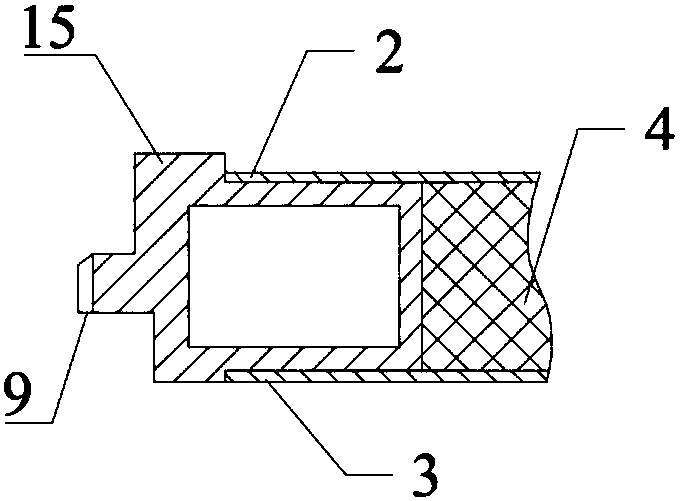

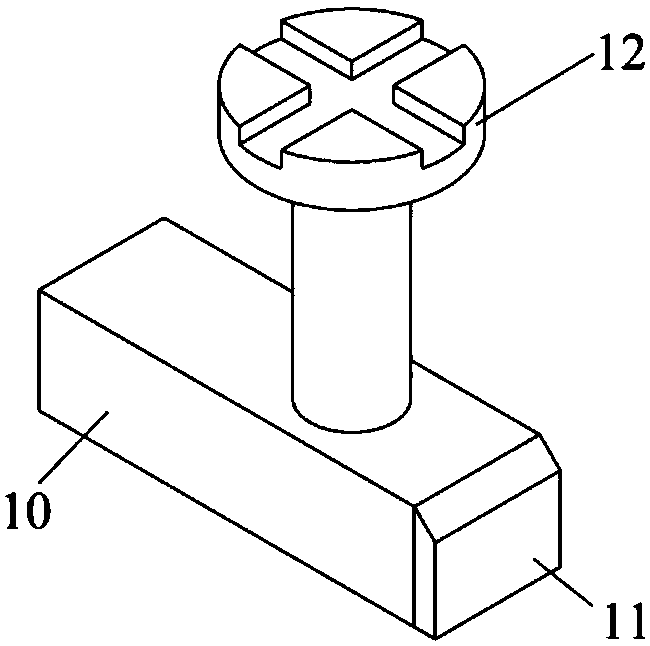

[0023] Such as Figure 4 As shown, the self-locking electric heating substrate for a rail transit vehicle comprises a mother plate 14 and a male plate 15 of an aluminum hollow profile frame, the frames of the motherboard 14 and the male plate 15 are shaped hollow aluminum profiles, and the mother plate 14 The lower surface of the outer edge of the cross-section has a three-step ladder structure, and the upper and lower surfaces of the inner side have a two-step ladder structure. The outer side of the cross section of the male plate 15 is provided with a boss structure, and the top of the boss structure is provided with a male buckle 9 . The inner sides of the main board 14 and the male board 15 are both lightweight and high-strength sandwich composite structures, which are composed of the upper panel 2, the lower panel 3, the foam core mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com