Wind power blade web plate, wind power blade and a die for preparing wind power blade web plate

A technology of wind turbine blades and webs, applied in the field of wind power generation, can solve problems such as the inability to meet the structural design requirements of large wind turbine blades, poor reliability and safety of wind turbine blades, and increased structural safety risks, so as to improve safety and reliability Sex, avoid the effects of small support range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

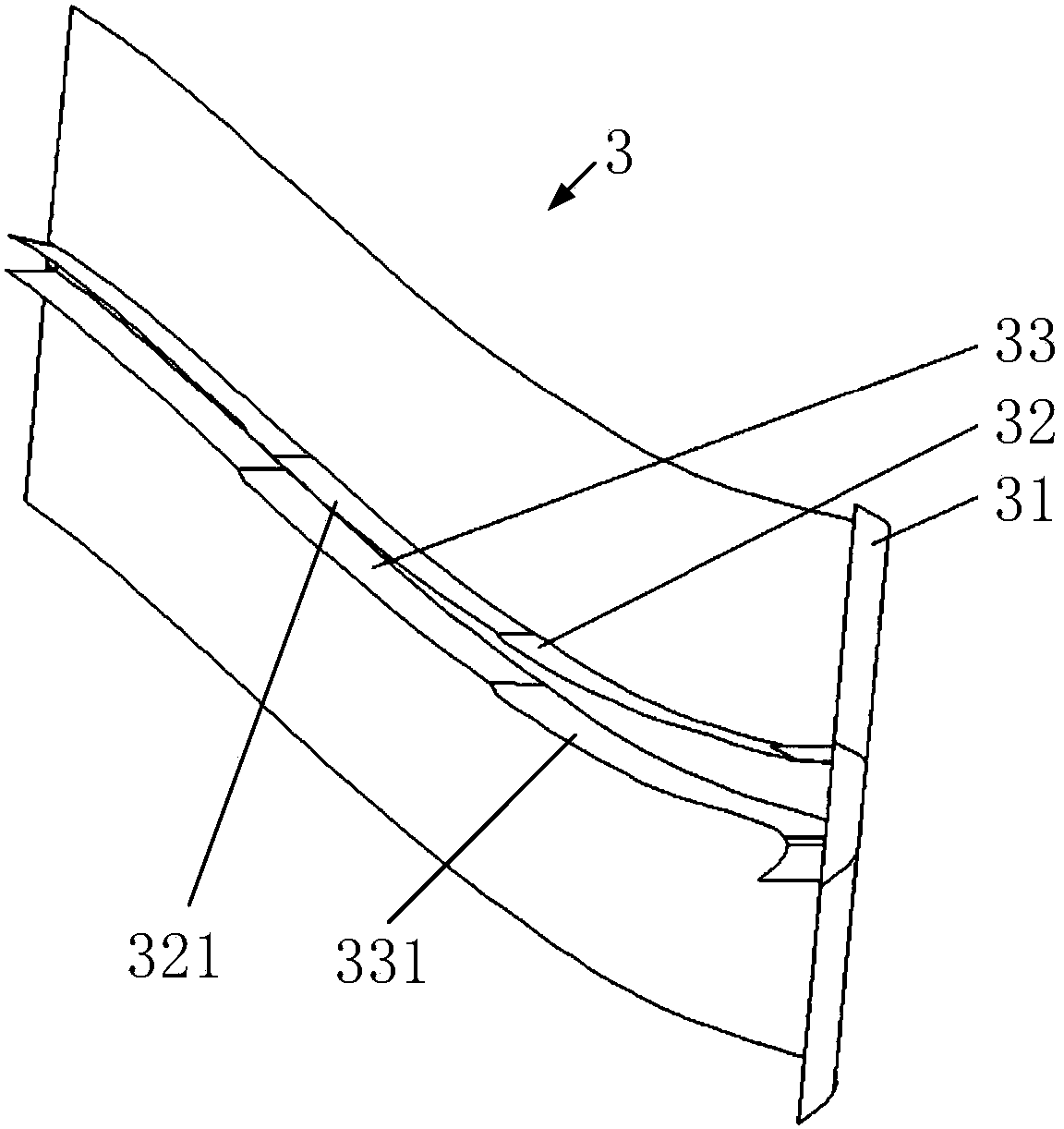

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

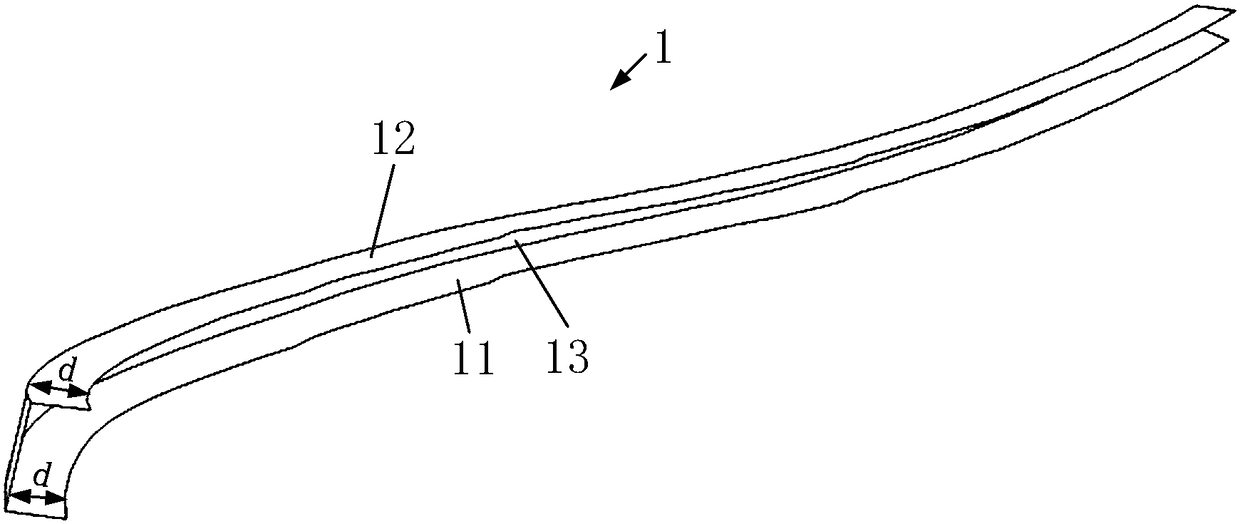

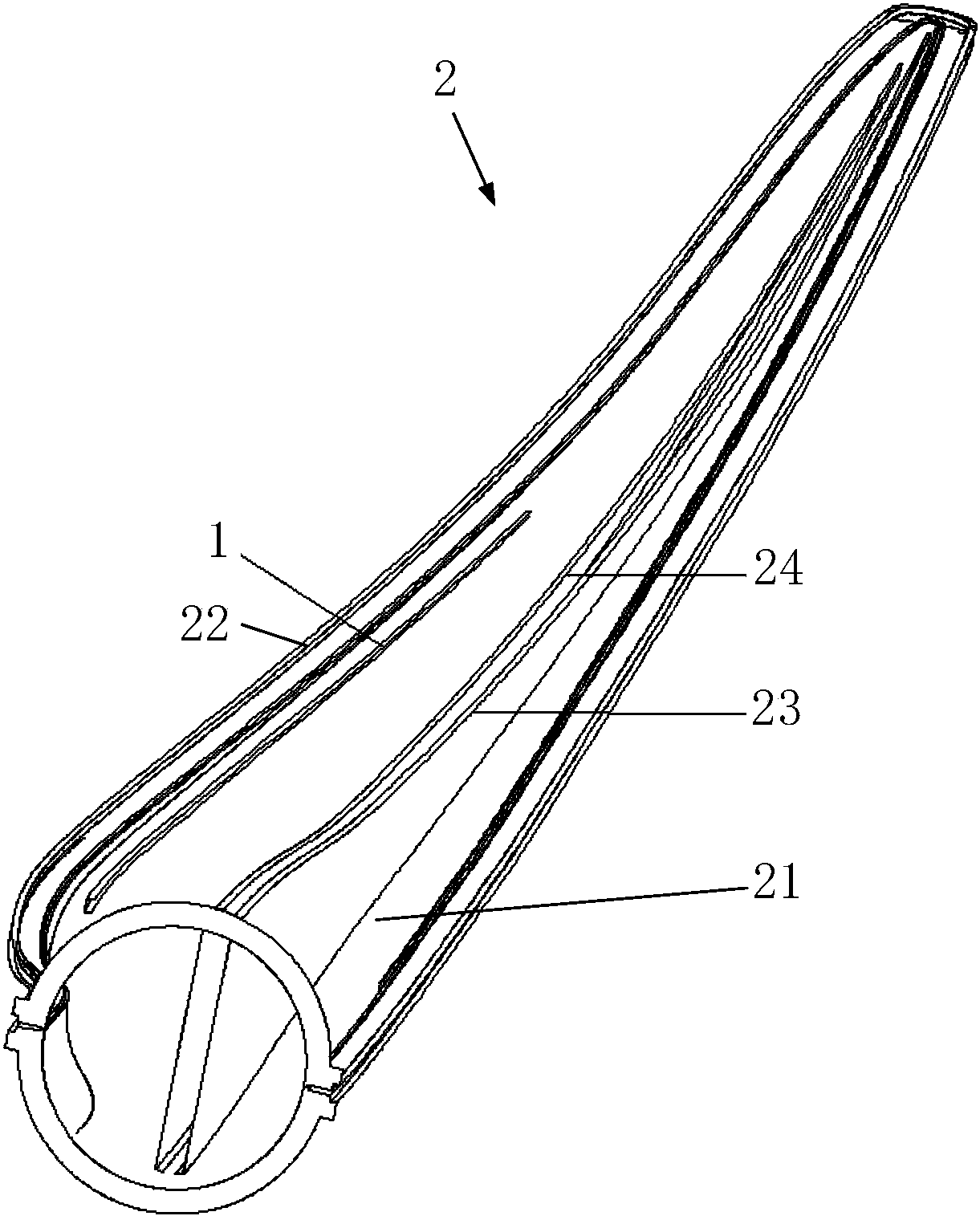

[0030] figure 1 The embodiment of the web of the wind power blade of the present invention is shown, the wind power blade web 1 is set in the cavity of the wind power blade 2 to play a supporting role, and bears the main load of the wind power blade 2 during the movement. In this embodiment, the wind turbine blade web 1 includes a suction surface bonding section 11 , a pressure surface bonding section 12 and a connecting curved surface section 13 . Wherein, the suction surface bonding section 11 is bonded to the blade suction surface; the pressure surface bonding section 12 is bonded to the blade pressure surface; the connecting curved surface section 13 is arranged between the suction surface bonding section 11 and the pressure surface bonding section 12, And ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com