Mold grinding and automatic cleaning method

A mold and grinding machine technology, applied in chemical instruments and methods, separation methods, grinding machines, etc., can solve the problems of dust damage to the human body, and achieve the effect of good grinding effect, reasonable structure and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

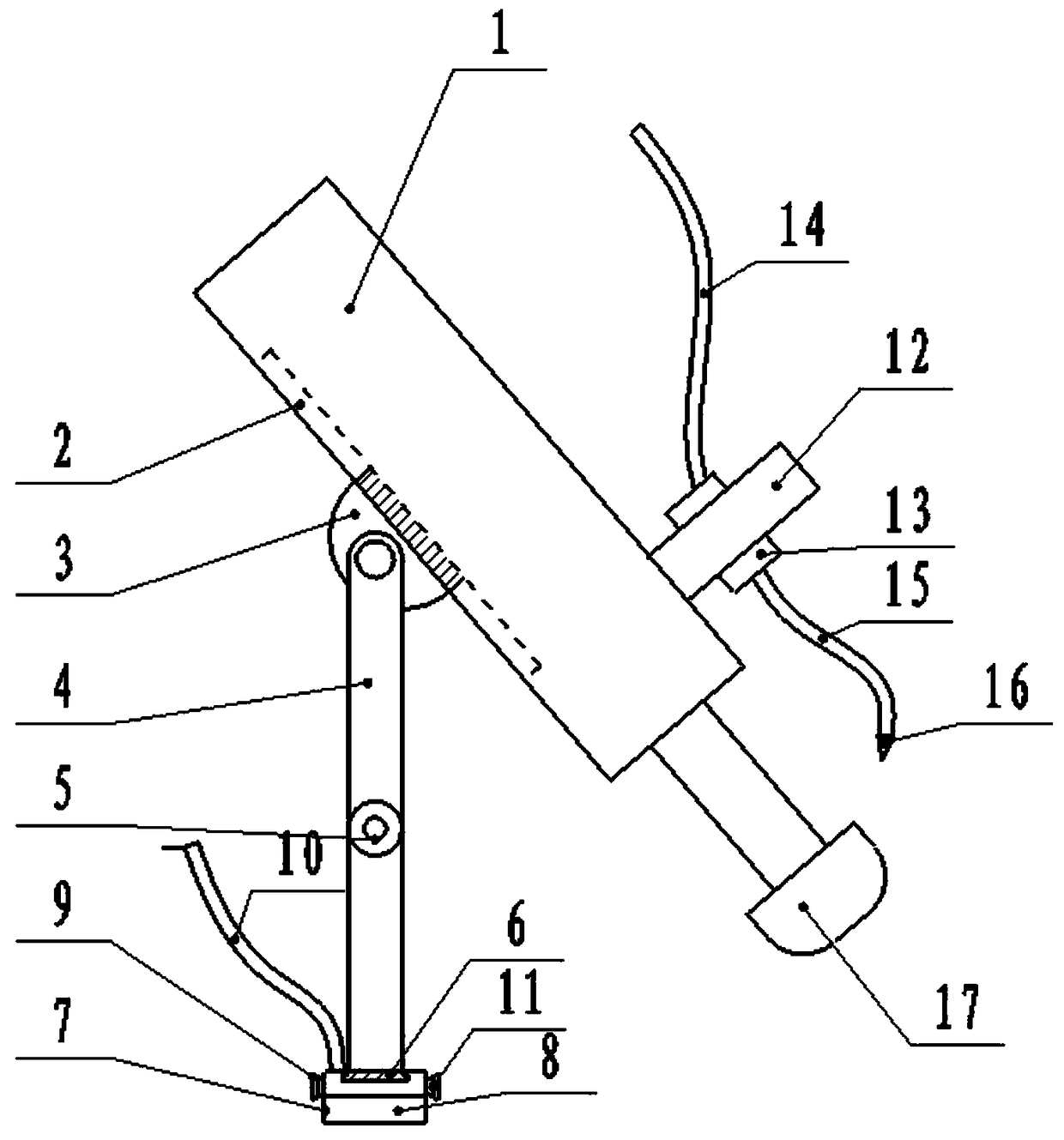

[0025] Such as figure 1 Shown, a kind of mold polishing automatic cleaning method of the present invention comprises steps:

[0026] Step 1. A chute 2 is provided on one side of the hand-held grinder 1. A hinged seat 3 is provided in the chute 2. The hinged seat 3 is hinged to a support rod 4, and the middle part of the support rod 4 is provided with a folding hinge shaft. 5;

[0027] Step 2 The bottom end of the support rod 4 is connected to the base 7 through the rotating block 6, the bottom of the base 7 is provided with an electromagnet 8, and the upper part of the base 7 is surrounded by a plurality of dust suction ports 9, and the dust suction port 9 are all communicated with the dust suction pipe 10, and a wire filter screen 11 is provided in the dust suction port 9;

[0028] Step 3. A support 12 is provided on the other side of the hand-held grinder 1, and an atomizer 13 is provided on the support 12. The upper side of the atomizer 13 is connected to a water inlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com