Nut demounting machine

A nut machine and nut technology, applied in ceramic molding machines, unloading devices, metal processing, etc., can solve the problems of low production efficiency, time-consuming and laborious, etc., and achieve the effects of high production efficiency, simple process and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

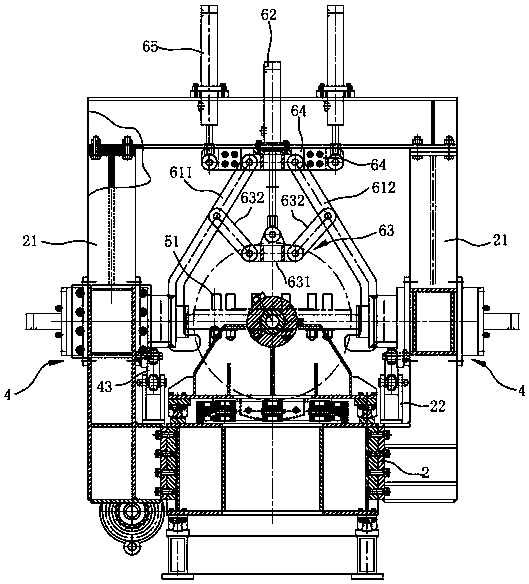

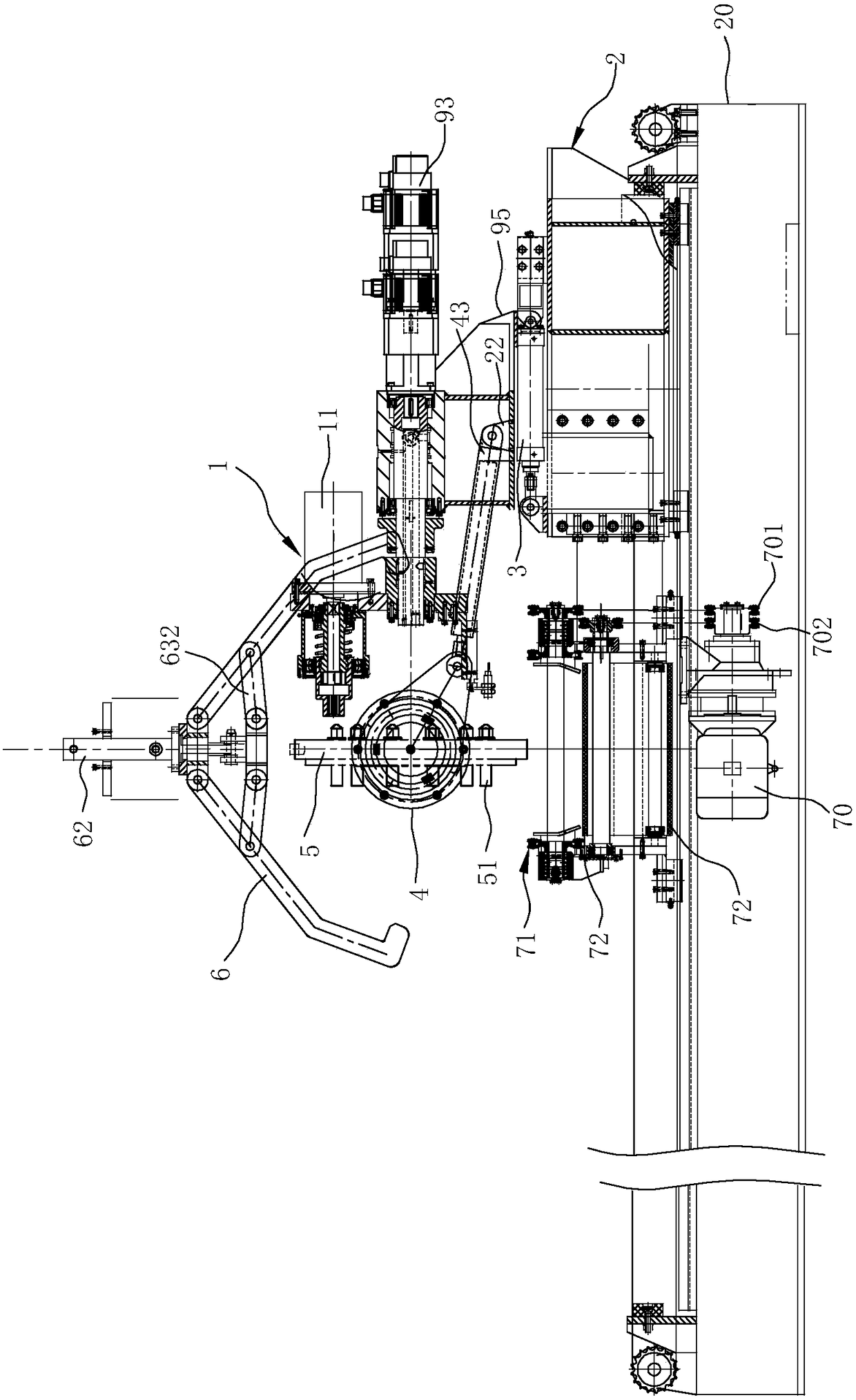

[0047] like Figure 1 to Figure 15 Shown is the first embodiment of the present invention. The nut removal machine of this embodiment includes an organic platform 2, a nut removal assembly 1 that is arranged on the machine platform 2 and disassembles the nuts on the end plate 5, a first drive mechanism 3, a turning mechanism 4 and a conveying mechanism, and a clamping mechanism. Take the clamping mechanism 6 of the end plate 5, wherein,

[0048] In this embodiment, the nut removal assembly 1 is arranged on the first support 95 of the machine table 2, and the first support 95 is provided with a ninth driving mechanism 951 for driving the nut removal assembly 1 to approach or move away from the end plate 5, and the nut removal The assembly 1 moves under the drive of the ninth driving mechanism 951 to facilitate the disassembly of the nuts on the end plate; specifically, when the nuts on the end plate are removed, the ninth driving mechanism drives the nut removal assembly 1 clo...

Embodiment 2

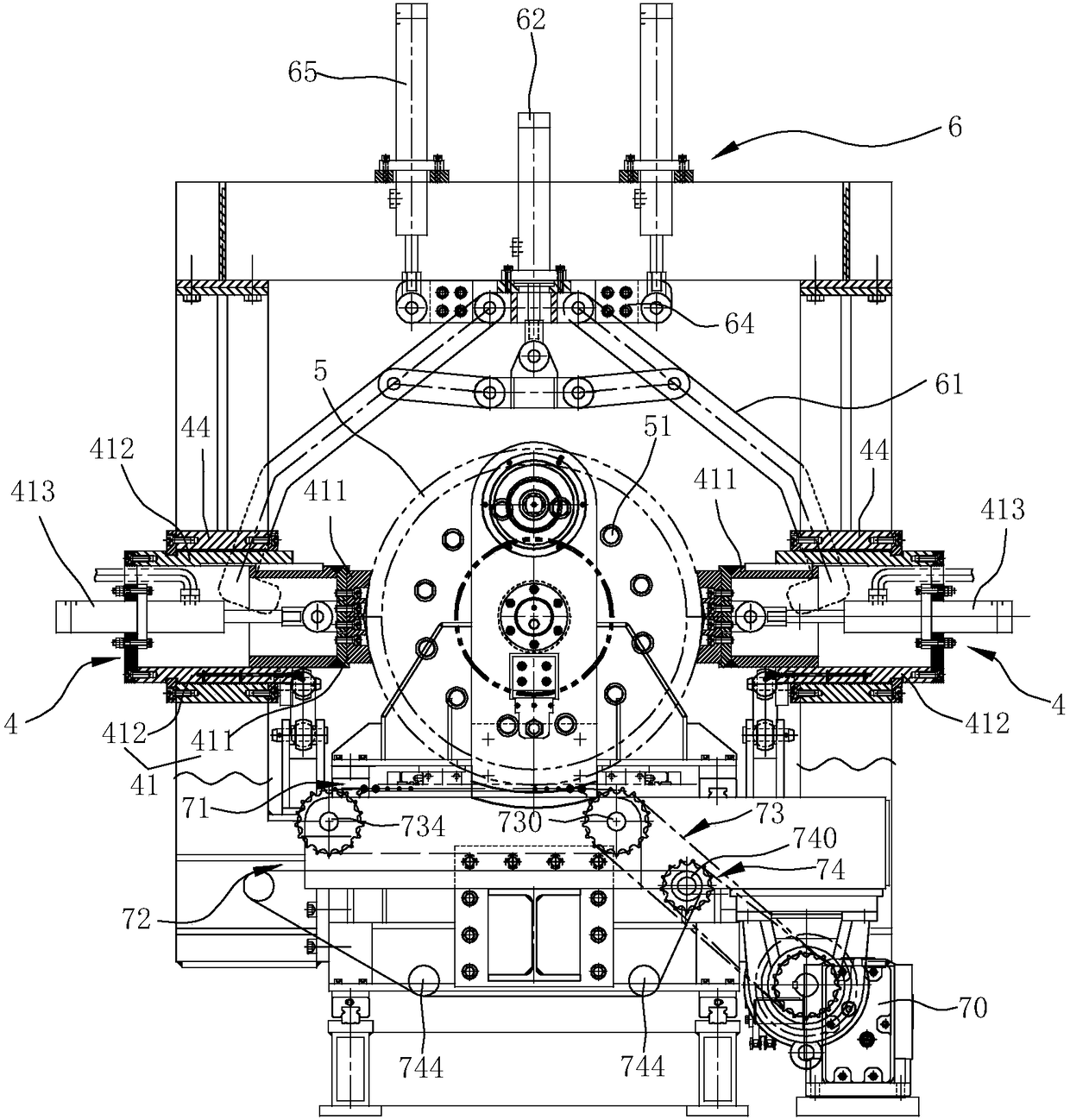

[0077] like Figure 16 to Figure 22 As shown, it is the second embodiment of the present invention. The difference between this embodiment and the above-mentioned embodiment one is: a. The first conveying mechanism 71 is fixedly connected with the second conveying mechanism 72, and the power output end of the seventh driving mechanism 70 A first sprocket 701 is connected, and the first sprocket 701 is in transmission connection with the first transmission mechanism 73 and is used to drive the first conveying mechanism 71 and the second conveying mechanism 72 to move synchronously.

[0078] b. The circumferential limit structure between the demoulding shaft 12 and the output shaft 111 of the air motor 11 is different: the output shaft 111 of the motor 11 is inserted into the socket 122 of the demoulding shaft 12, and the outer peripheral wall of the output shaft 111 and The inner peripheral walls of the insertion holes 122 are respectively provided with key grooves 110, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com