A kind of rare earth methanation catalyst and its preparation method and application

A technology of methanation catalyst and rare earth compound, which is applied in the field of rare earth methanation catalyst and its preparation, can solve the problems of unsatisfactory anti-coking and poor stability, and achieve the effect of good carbon resistance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

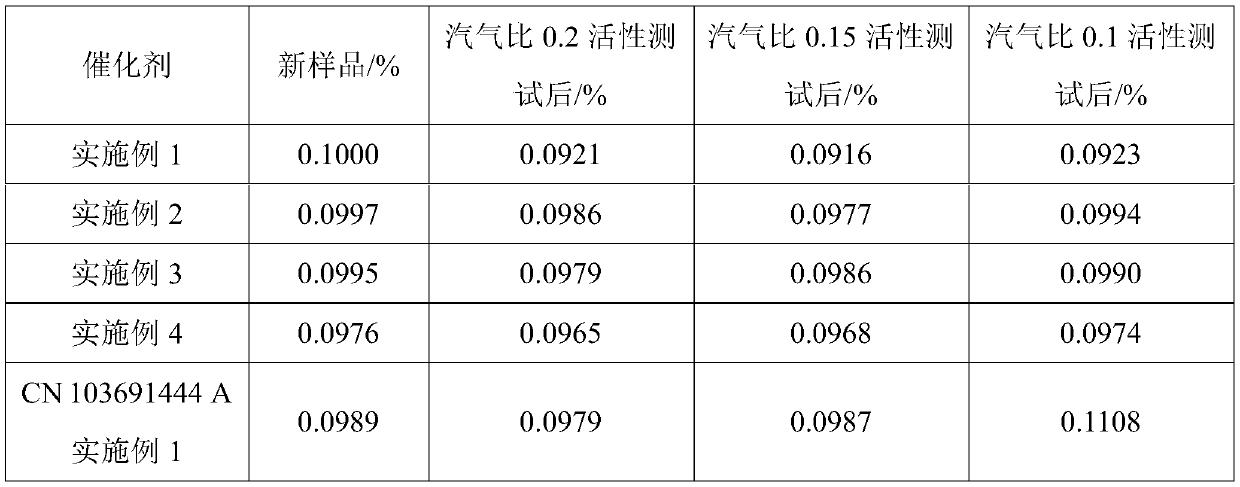

Embodiment 1

[0036] This embodiment provides the preparation of the rare earth methanation catalyst of the present invention, which specifically includes the following steps:

[0037] (1) 10g of calcium nitrate, 25g of magnesium nitrate and 75g of auxiliary aluminum nitrate are prepared to make a mixed solution of 1000mL, and then the mixed solution is heated to 50-70°C and then loaded into the constant temperature storage tank 1;

[0038] (2) Set the concentration of 500mL as Na 2 CO 3 10% is heated to 50-70°C and loaded into the constant temperature storage tank 2;

[0039] (3) After adding 700mL of water to 70g kaolin to prepare a suspension, put it into the reactor; mix the mixed solution in the constant temperature storage tank 1 and the Na 2 CO 3 The solution is simultaneously added to the reactor containing the kaolin suspension to react, and the mixed solution and Na 2 CO 3 The speed of adding the solution keeps the pH of the reaction system at 7.0-8.5, and the reaction time ...

Embodiment 2

[0045] This embodiment provides the preparation of the rare earth methanation catalyst of the present invention, which specifically includes the following steps:

[0046] (1) 12g of calcium nitrate, 30g of magnesium nitrate and 70g of auxiliary aluminum nitrate are prepared to make a mixed solution of 1000mL, and then the mixed solution is heated to 50-70°C and then loaded into the constant temperature storage tank 1;

[0047] (2) Set the concentration of 500mL as Na 2 CO 3 10% is heated to 50-70°C and loaded into the constant temperature storage tank 2;

[0048] (3) After adding 72g of kaolin and 1440mL of water to prepare a suspension, put it into the reactor; mix the mixed solution in the constant temperature storage tank 1 and the Na 2 CO 3 The solution is simultaneously added to the reactor containing the kaolin suspension to react, and the mixed solution and Na 2 CO 3 The speed of adding the solution keeps the pH of the reaction system at 7.0-8.5, and the reaction ...

Embodiment 3

[0054] This embodiment provides the preparation of the rare earth methanation catalyst of the present invention, which specifically includes the following steps:

[0055] (1) 20g of calcium nitrate, 20g of magnesium nitrate and 66g of auxiliary aluminum nitrate were prepared to make a mixed solution of 1000mL, and then the mixed solution was heated to 50-70°C and then loaded into the constant temperature storage tank 1;

[0056] (2) Set the concentration of 500mL as Na 2 CO 3 10% is heated to 50-70°C and loaded into the constant temperature storage tank 2;

[0057] (3) After adding 1000mL of water to 78g kaolin to prepare a suspension, put it into the reactor; mix the mixed solution in the constant temperature storage tank 1 and the Na 2 CO 3 The solution is simultaneously added to the reactor containing the kaolin suspension to react, and the mixed solution and Na 2 CO 3 The speed of adding the solution keeps the pH of the reaction system at 7.0-8.5, and the reaction ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com