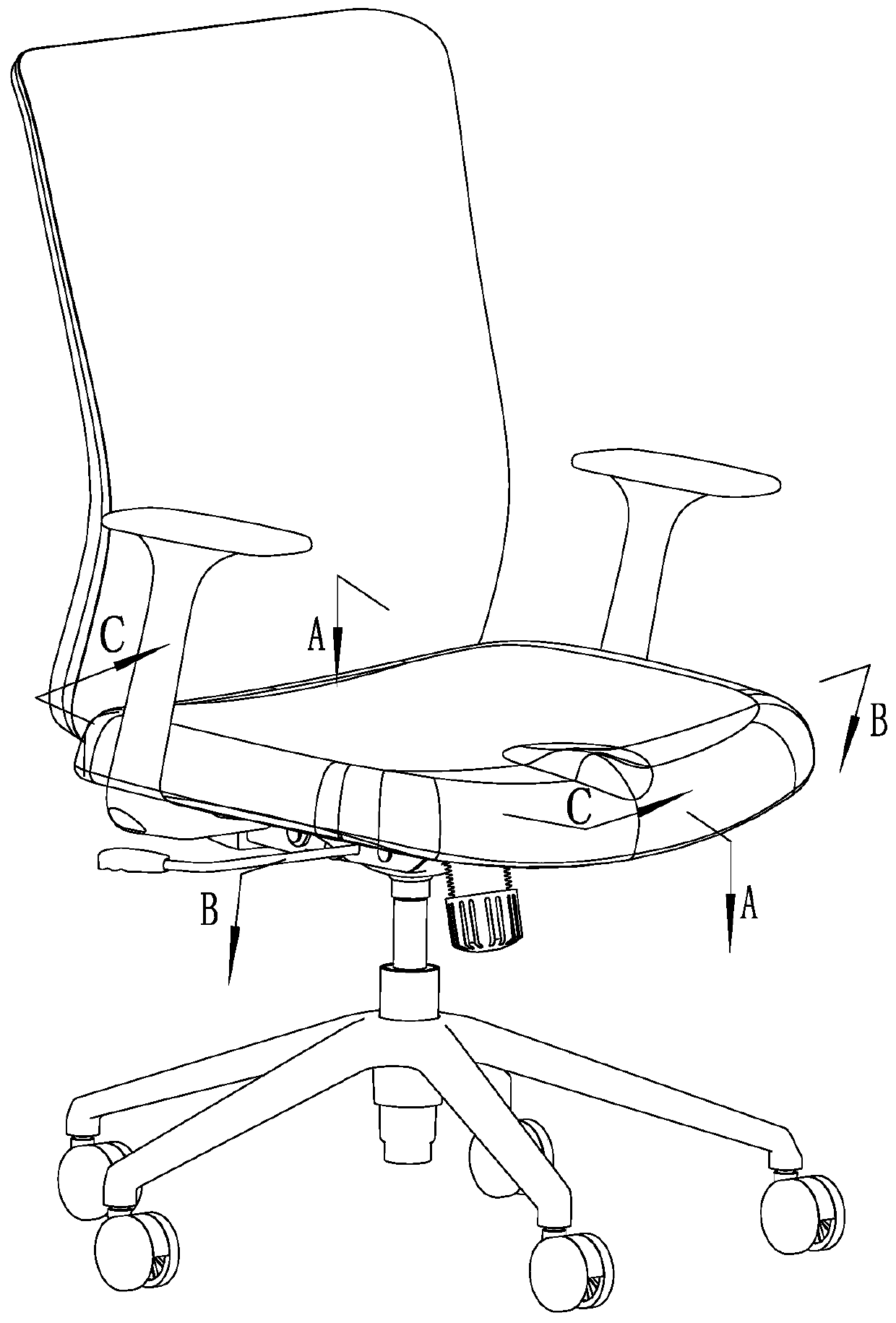

A kind of elastic layered cushion and seat

A cushion and elasticity technology, applied in the field of elastic layered cushions and seats, can solve the problems of not having massaged human acupuncture points, slow blood flow in the thighs, and no comfort, so as to reduce office diseases, increase elasticity, and improve comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

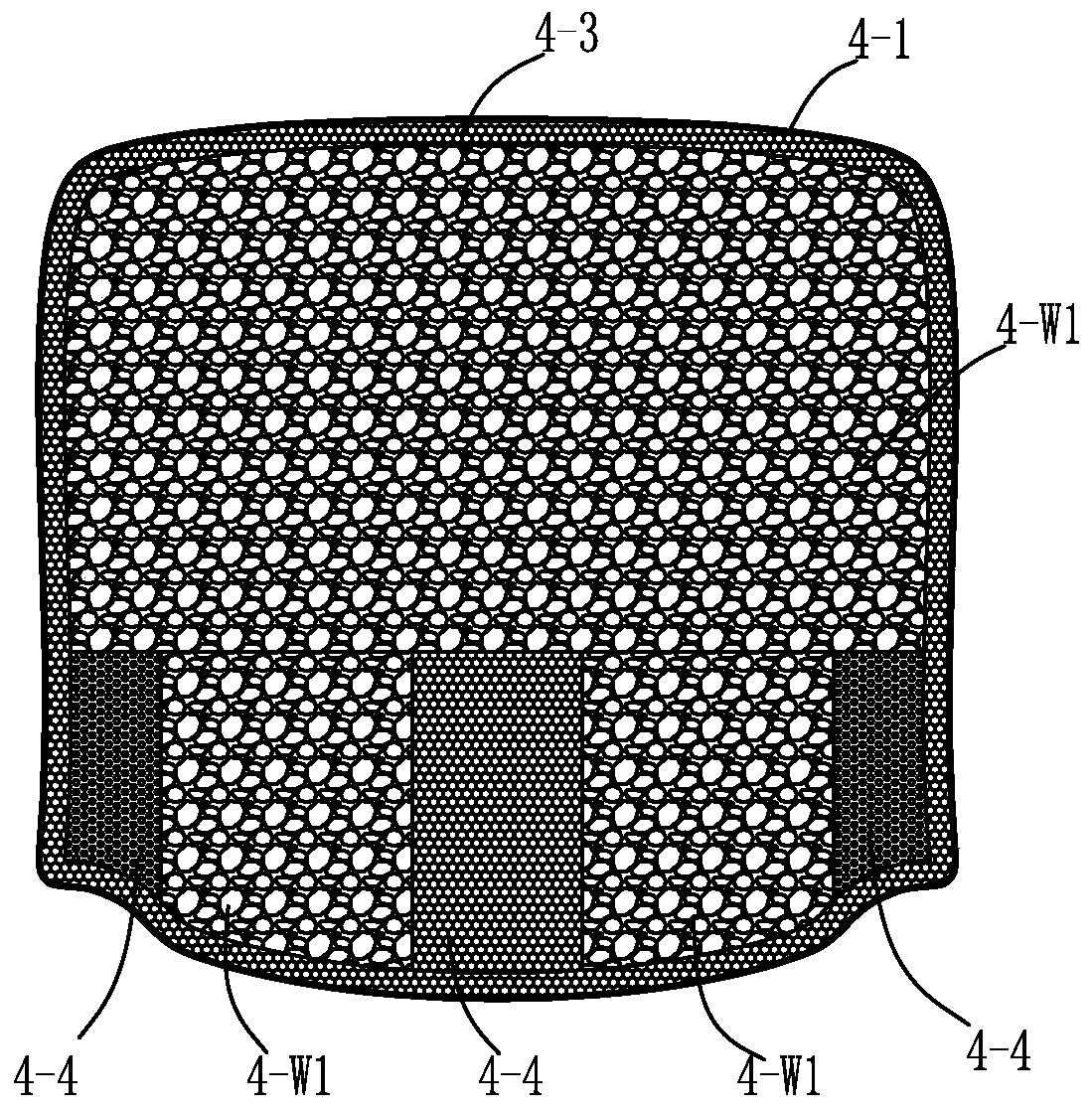

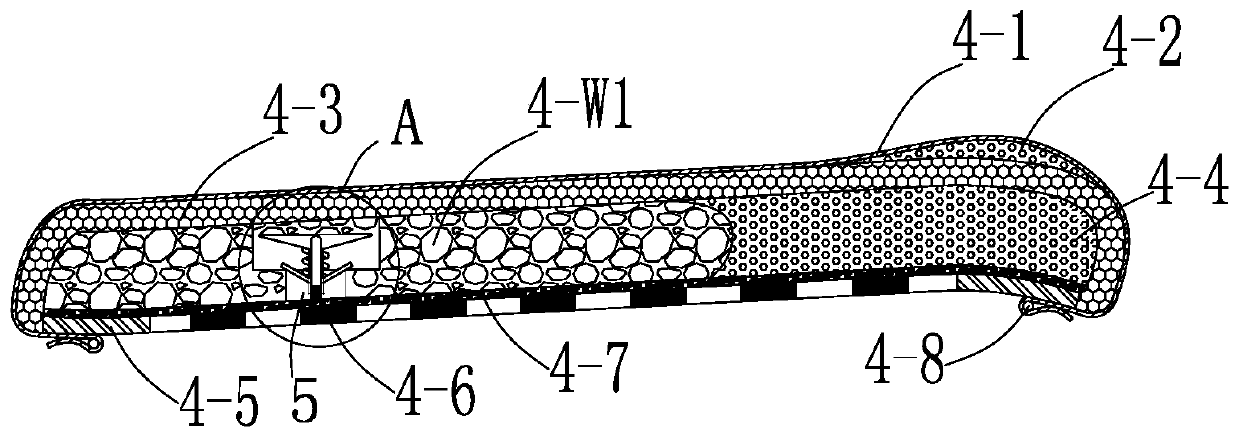

[0043] Embodiment one: if Figure 1-5 As shown, an elastic layered cushion, which sequentially includes the first cushion layer 4-3, the second cushion layer 4-W1, the third cushion layer 4-7 and the fourth cushion layer 4-5 from top to bottom, so The first cushion layer 4-3 extends downwards until it is flush with the end of the fourth cushion layer 4-5, and the second cushion layer 4-W1, the third cushion layer 4-7, and the fourth cushion layer 4-5 are respectively wrapped inside. The thickness percentages of the cushion layers are: the first cushion layer 4-3 15%-25%; the second cushion layer 4-W1 50%-70%; the third cushion layer 4-7 1%-10%; The fourth cushion 4-5 10%-15%.

[0044] The first cushion layer 4-3 is made of polyester fiber polyurethane material, the second cushion layer 4-W1 is made of thermoplastic polyetherester air fiber, the third cushion layer 4-7 is made of suede, and the second cushion layer 4-W1 is made of suede. Four cushions 4-5 are made of plywood...

Embodiment 2

[0057] Embodiment two: if Figure 4-8 As shown, the difference between this embodiment and Embodiment 1 is that the front part of the second cushion layer 4-W1 is not set only for the thigh load action area, and the fifth cushion layer 4-4 and the sixth cushion layer 4-4 are canceled in this embodiment. As a cushion layer, the second cushion layer 4-W1 replaces the fifth cushion layer 4-4 and the sixth cushion layer. The layered cushion of the present embodiment is convenient for processing and making.

Embodiment 3

[0058] Embodiment three: as Figure 9-11 As shown, the difference between this embodiment and the first embodiment is that the thickness and density of the second cushion layer 4-W1 are greater than that of the first embodiment, because the greater the thickness and density of the thermoplastic polyetherester air fibers, the more layered The better the elasticity of the cushion, so the elastic performance of this embodiment is greater than that of Embodiment 1, different thermoplastic polyether ester air fibers can be selected according to the different requirements of the product for elastic performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com