On-line detection system and method for droplet deposition during spraying operation of equipment for plant protection

A technology for detection system and deposition amount, which is applied in the direction of measuring device, injection device, particle and sedimentation analysis, etc., which can solve the problems of cumbersome operation, heavy workload, and inability to detect in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution and device structure of the present invention are clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention:

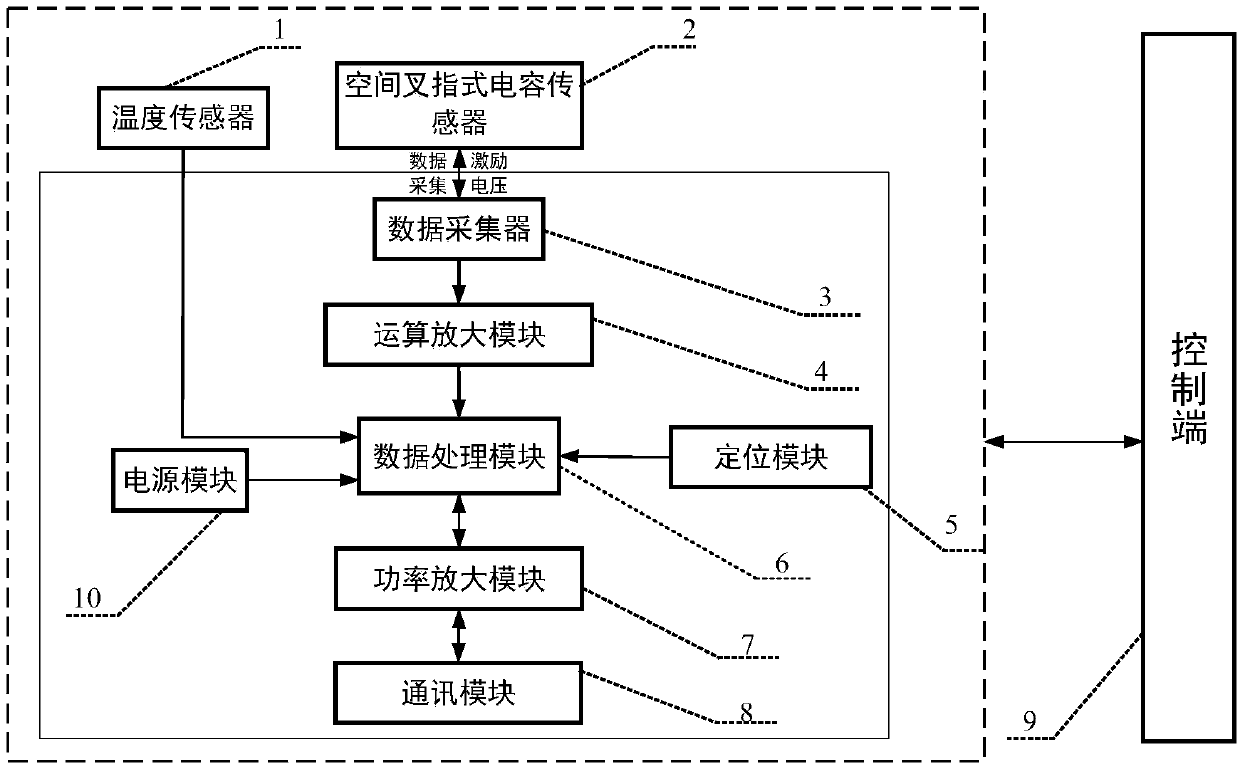

[0023] like figure 1 As shown, it is a schematic structural diagram of an on-line detection system for spraying droplet deposition of plant protection machinery provided by an embodiment of the present invention. The system combines wireless sensor network technology and droplet deposition sensors to complete data collection and processing. The system includes a temperature sensor 1, a space interdigitated capacitance sensor 2, a data collector 3, an operational amplification module 4, a positioning module 5, a data processing module 6, a power amplification module 7, a communication module 8, a control terminal 9 and a power supply module 10. The temperature sensor 1, the positioning module 5, and the power module 10 are directly connected to the data processing modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com